A kind of method for preparing 2-ethylhexanal

A technology of ethylhexanal and ethyl, which is applied in the field of preparation of 2-ethylhexanal, can solve the problems of low catalyst processing capacity, high energy consumption in separation process, and three wastes of heavy components, achieves considerable economic benefits, and reduces choice Sexuality, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

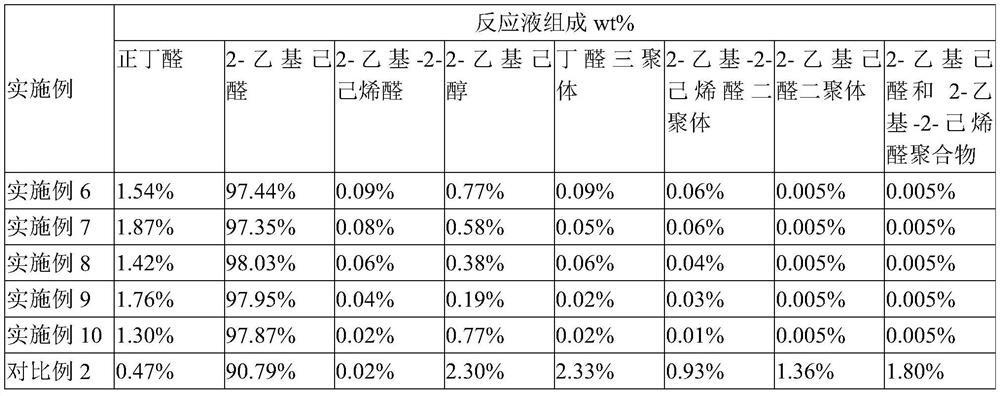

Examples

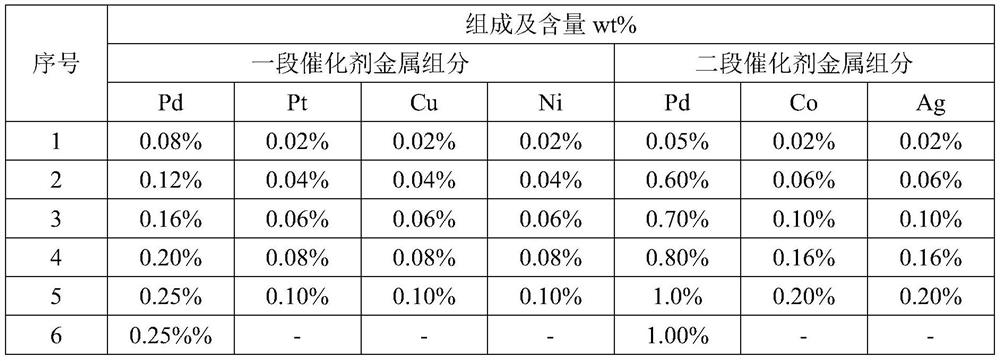

Embodiment 1

[0054] One-stage catalyst preparation:

[0055] Add 65.6L of deionized water to the reaction kettle, and then add 998.6g of nano-alumina with a particle size of 20-50nm to prepare a nano-oxide dispersion, and the temperature of the dispersion is 75°C;

[0056] Weigh 1.73g Pd(NO 3 ) 2 , 0.33gPt(NO 3 ) 2 , 0.59gCu(NO 3 ) 2 , 0.62gNi(NO 3 ) 2 , add 323.95g of water, and add the obtained mixed salt solution and alkaline precipitant sodium carbonate into the nano-oxide dispersion liquid for reaction at the same time, the reaction temperature is 80°C, the dropwise addition time is 2h, and the pH of the reaction system is controlled to be 6 during the reaction process. After the dropwise addition, add an alkaline precipitant to adjust the pH to 8, then age at 90°C for 1.5 hours to obtain a slurry;

[0057] The slurry was filtered, washed, and dried at 100°C for 18 hours to obtain a filter cake; then roasted at 1000°C for 8 hours, crushed, pressed into tablets, reduced at 135°...

Embodiment 2

[0064] One-stage catalyst preparation:

[0065] Add 98.8L of deionized water to the reaction kettle, and then add 997.6g of nano-titanium oxide with a particle size of 20-50nm to prepare a nano-oxide dispersion, and the temperature of the dispersion is 75°C;

[0066] Weigh 2.60g Pd(NO 3 ) 2 , 0.65gPt(NO 3 ) 2 , 1.18gCu(NO 3 ) 2 , 1.25gNi(NO 3 ) 2 , add 372.8g of water, and add the obtained mixed salt solution and alkaline precipitant potassium bicarbonate into the nano-oxide dispersion liquid for reaction at the same time. The reaction temperature is 85°C, and the dropping time is 2.5h. 5. After the dropwise addition, add an alkaline precipitant to adjust the pH to 7.5, and then age, the aging temperature is 85°C, and the aging time is 1h to obtain a slurry;

[0067] The slurry was filtered, washed, and dried at 100°C for 12 hours to obtain a filter cake; then roasted at 800°C for 10 hours, crushed, pressed into tablets, reduced at 120°C and 5 MPa for 24 hours, and dried...

Embodiment 3

[0074] One-stage catalyst preparation:

[0075] Add 198.3L of deionized water to the reaction kettle, and then add 996.6g of nano-zirconia with a particle size of 20-50nm to prepare a nano-oxide dispersion, and the temperature of the dispersion is 75°C;

[0076] Weigh 3.46g Pd(NO 3 ) 2 , 0.98gPt(NO 3 ) 2 , 1.77gCu(NO 3 ) 2 , 1.87gNi(NO 3 ) 2 , add 1608.80g of water, and add the obtained mixed salt solution and alkaline precipitant ammonium bicarbonate into the nano-oxide dispersion liquid for reaction at the same time, the reaction temperature is 85°C, and the dropping time is 2.5h. During the reaction, the pH of the reaction system is controlled to 7. After the dropwise addition, add an alkaline precipitant to adjust the pH to 8.5, and then age, the aging temperature is 90°C, and the aging time is 2 hours to obtain a slurry;

[0077] The slurry was filtered, washed, and dried at 100°C for 24 hours to obtain a filter cake; then roasted at 1200°C for 5 hours, crushed, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com