Steel wire liner conveyor belt joint sensing device

A technology for sensing devices and conveyor belts, which is applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve the problems of hall sensor deafness, low recognition rate, and easy fall-off of magnetic nails, so as to reduce energy consumption, Extended equipment life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

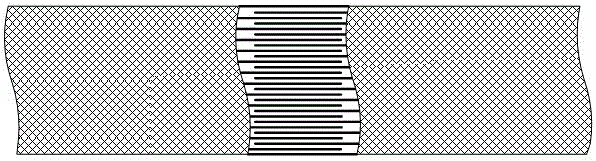

[0024] A steel wire-lined conveyor belt joint sensing device, comprising a housing 4, a base 12, a screw 8, a magnetic steel 10, a magnetic steel fixing frame 9, magnetic collecting blocks 14, 16, and a Hall sensor module 15, see image 3 ;

[0025] The two ends of the screw 8 are supported on the base 12 through the internal thread holes of the two fixing frames 5 and 13, the magnetic steel 10 is installed on the magnetic steel fixing frame 9, the magnetic steel 10 is made of rare earth, and the screw rod 8 passes through the magnetic steel Threaded holes on the fixed mount 9 enable the magnetic steel fixed mount 9 to move along the screw rod 8 . The magnetic collecting blocks 16, 14 are two pieces up and down, and the Hall sensor module 15 is housed in the gap between the two magnetic collecting blocks 14, 16, and the gap forms a connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com