Combined type drying room

A combination and drying room technology, applied in the direction of separation method, coating, pretreatment surface, etc., can solve the problems of increased area occupied by the drying room, energy consumption and equipment cost, etc., and achieve overall energy consumption reduction, energy consumption The effect of reducing and reducing the floor area and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

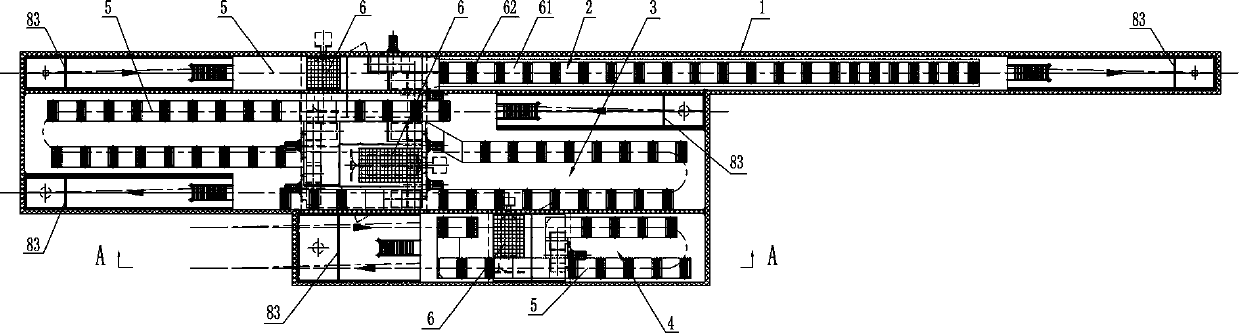

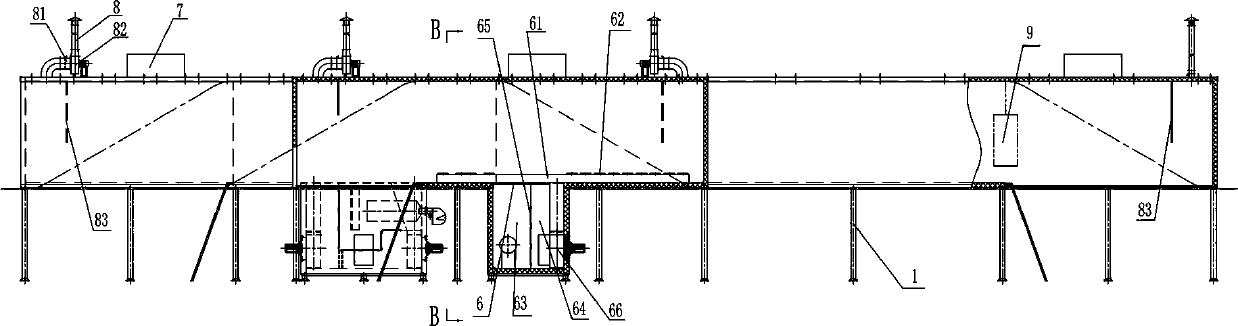

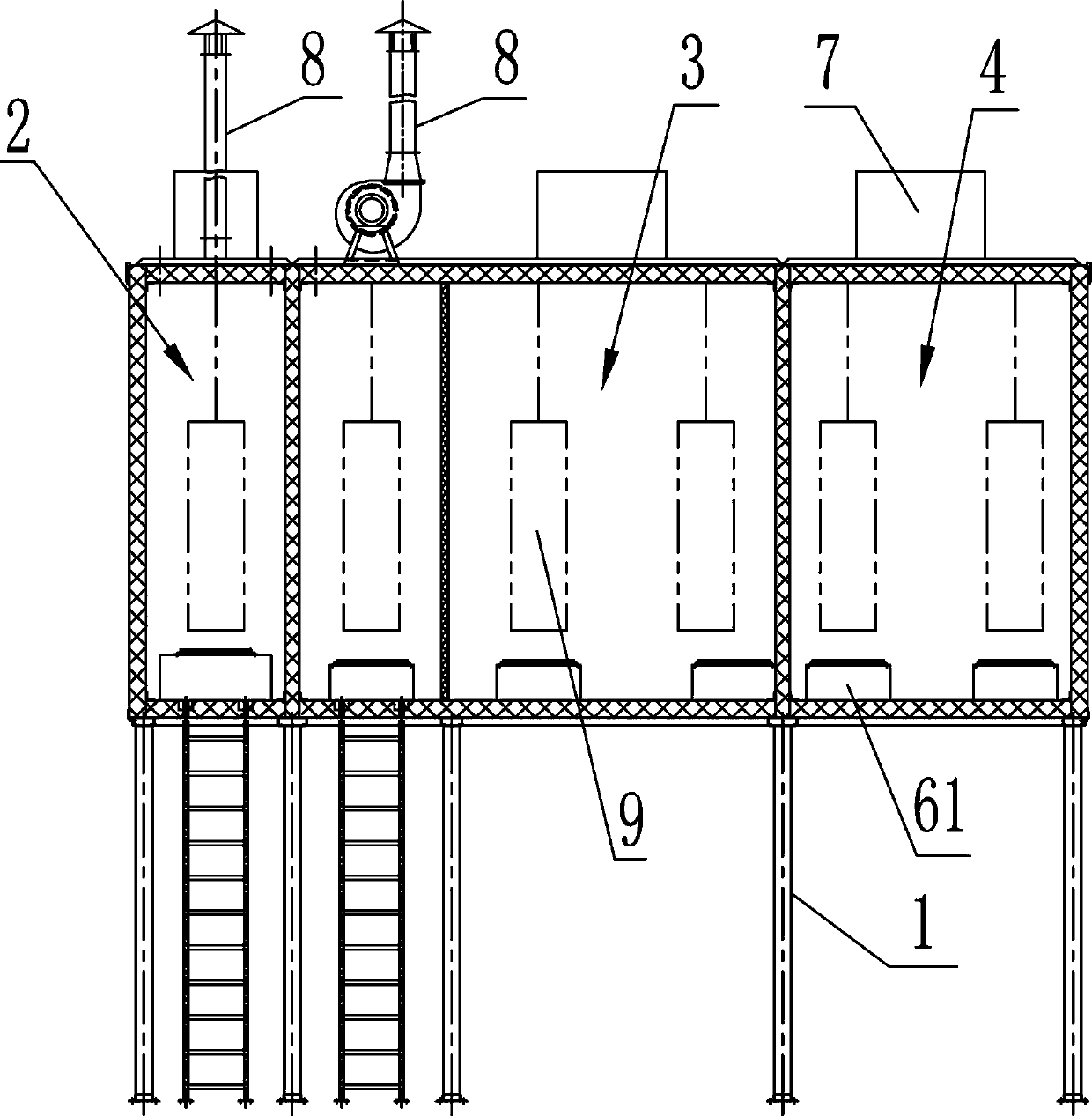

[0015] Such as figure 1 As shown, a combined drying room includes: a frame 1, and three drying rooms sharing the side walls between them are arranged side by side on the frame 1, which are respectively: used for drying super-long workpieces after dusting The first drying room for curing 2, the second drying room for drying and curing small-sized workpieces after powder spraying, the third drying room 4 for drying and drying small-sized workpieces after pretreatment, and the three drying rooms share the side After the wall is installed, the equipment cost and floor area can be greatly reduced. The drying temperature of the first and second drying rooms 2 and 3 is higher than that of the third drying room 4. The length of the first drying room 2 is longer than that of the second drying room 3. The length of the second drying room 3 is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com