RCO waste gas treatment device and treatment method thereof

A waste gas treatment device and waste gas technology are applied in the direction of combustion methods, combustion types, incinerators, etc., which can solve the problems of large floor space, large volume, and increased equipment costs of enterprises, and achieve reduction of floor space and equipment costs, and shrink volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the present invention will be described in conjunction with the drawings in the present invention, and is clearly, and it is intended to be described herein, not all of the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments in the present invention, all other embodiments obtained without making creative labor without making creative labor.

[0037]Aiming at the cost of the RCO exhaust gas treatment apparatus in the prior art, thereby leading to a technical issue of equipment costs that cover an area of equipment and invisible enterprises.

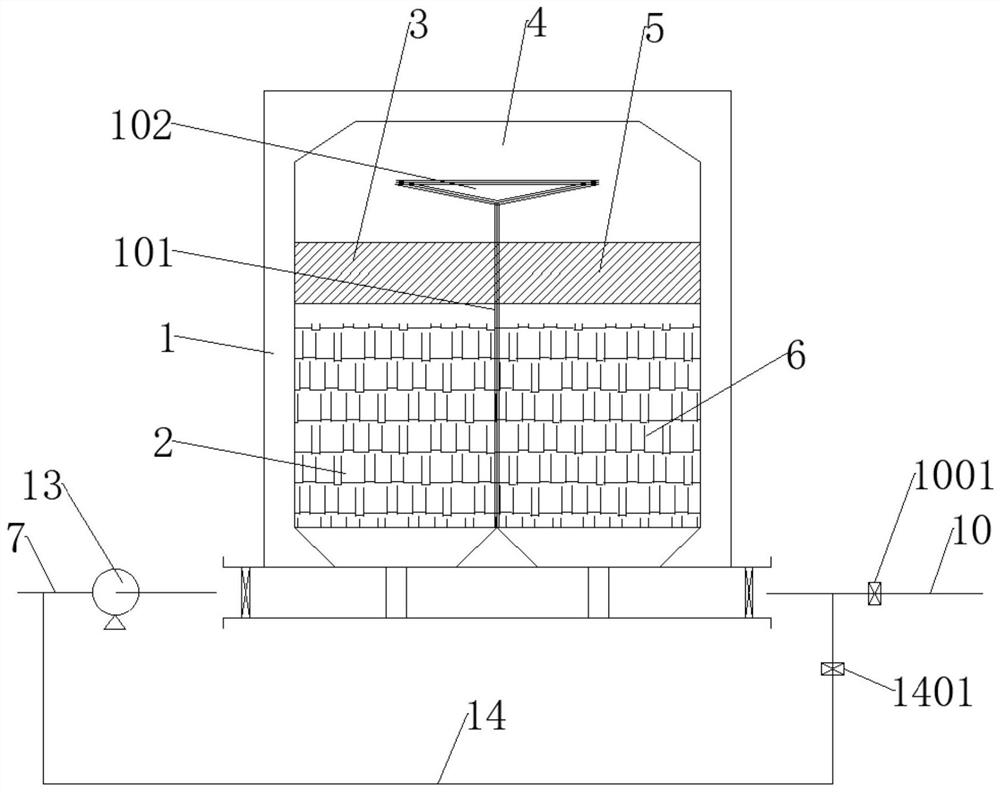

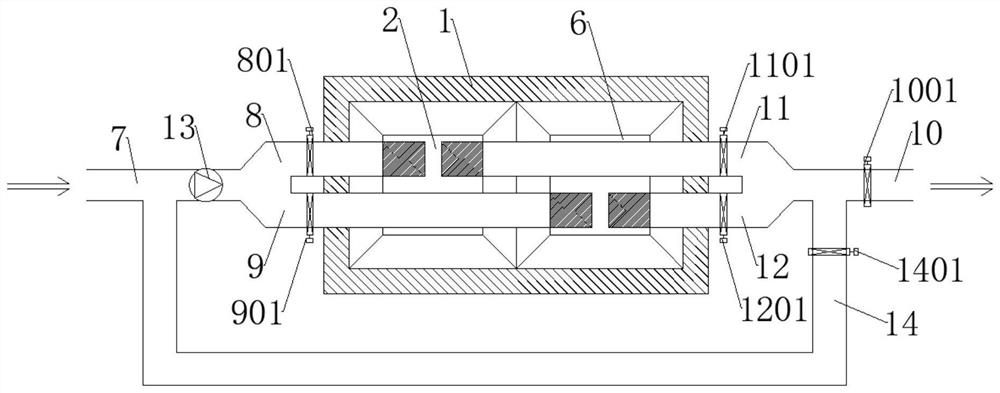

[0038] This example discloses an RCO exhaust gas treatment device, reference attached Figure 1-2 The inside of the casing 1 is included, and the inside of the casing 1 is sequentially provided with an electric storage zone, a catalytic region, and a heating zone 4; wherein the interior of the casing 1 is provided with a separator 101, and the separator 101 will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com