Flexible polishing unit of casting robot

A technology of robots and castings, which is applied in the direction of manipulators, grinding workpiece supports, manufacturing tools, etc., can solve the problems that cannot be polished, and achieve the effect of saving floor space and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

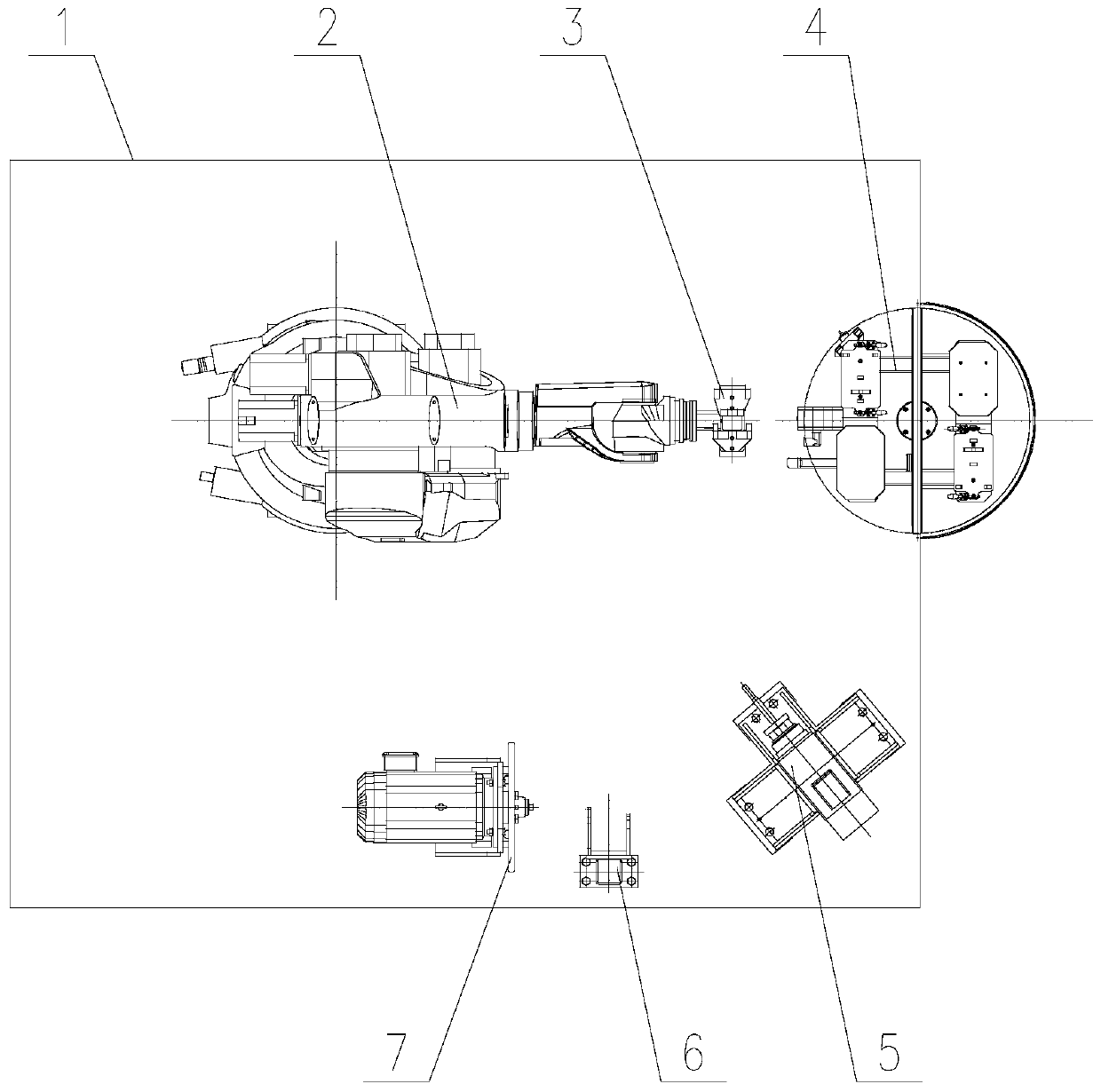

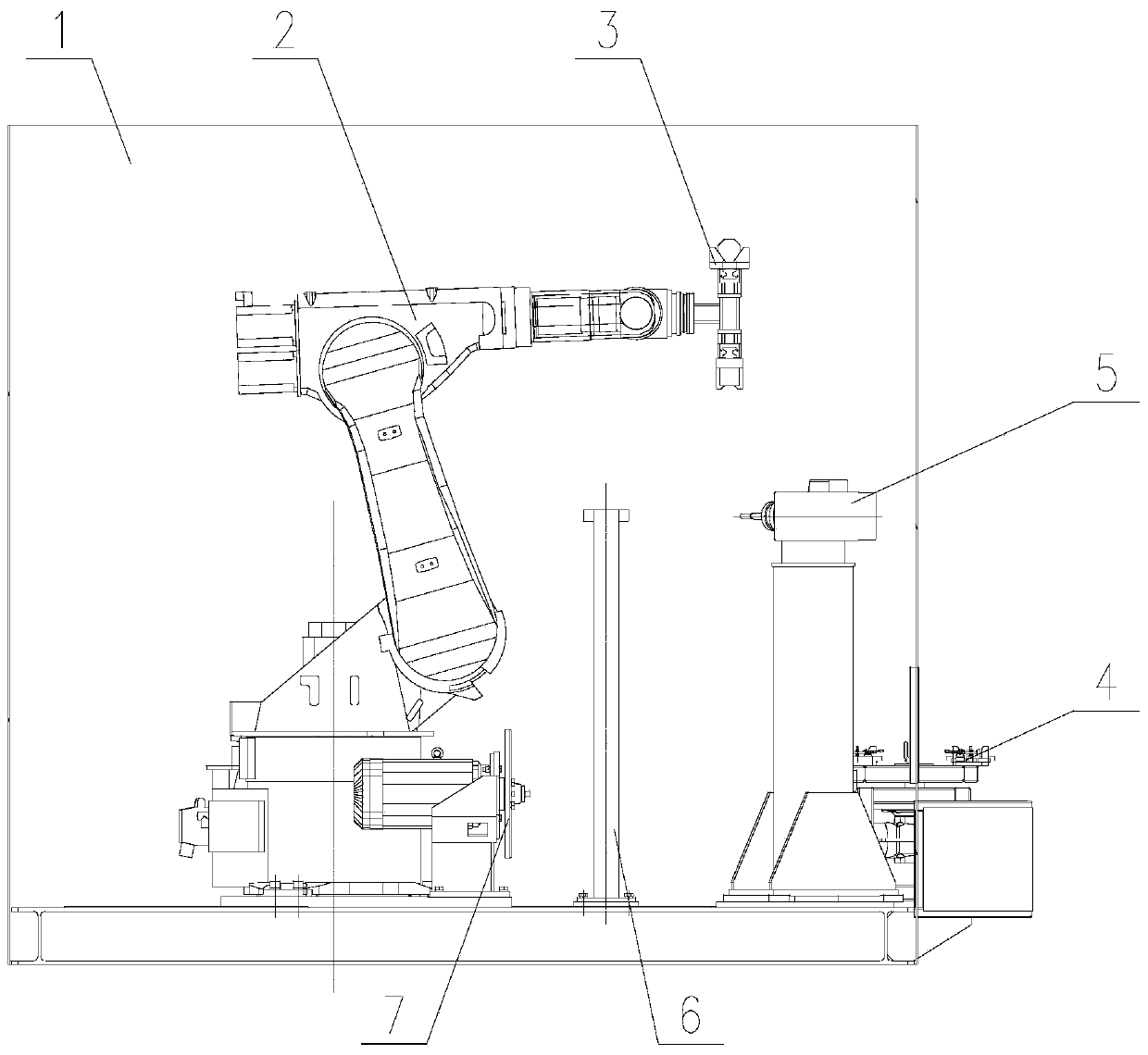

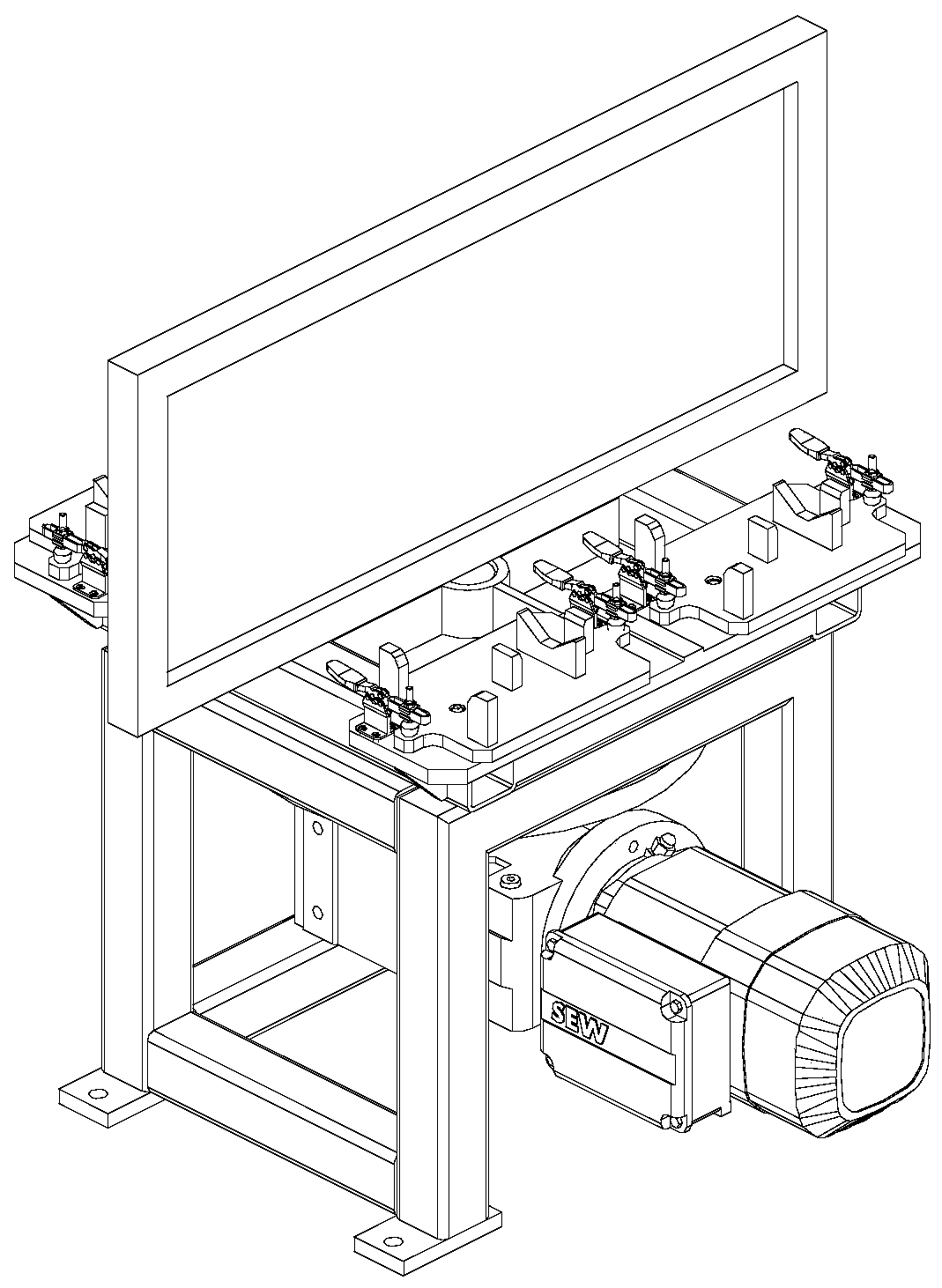

[0020] Such as figure 1 As shown, the casting robot flexible grinding unit of the present invention includes a dust removal soundproof cover 1, a robot 2, a clamp 3, a loading and unloading turntable 4, a first fixed power head 5, a second fixed power head 7, an adapter bracket 6, and a dust removal The soundproof cover covers the entire grinding unit, and a dust removal interface (not shown) is left to communicate with the dust removal pipe in the workshop, which plays the role of isolating dust, noise and safety protection. The robot, as a motion carrier, is equipped with a corresponding The fixture 3 passes through the fixture 3 and transports the casting and feeds and grinds; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com