Catalyst for synergistically purifying multiple pollutants in adipic acid device and preparation and application thereof

A composite catalyst, dual-function catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, adipic acid production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

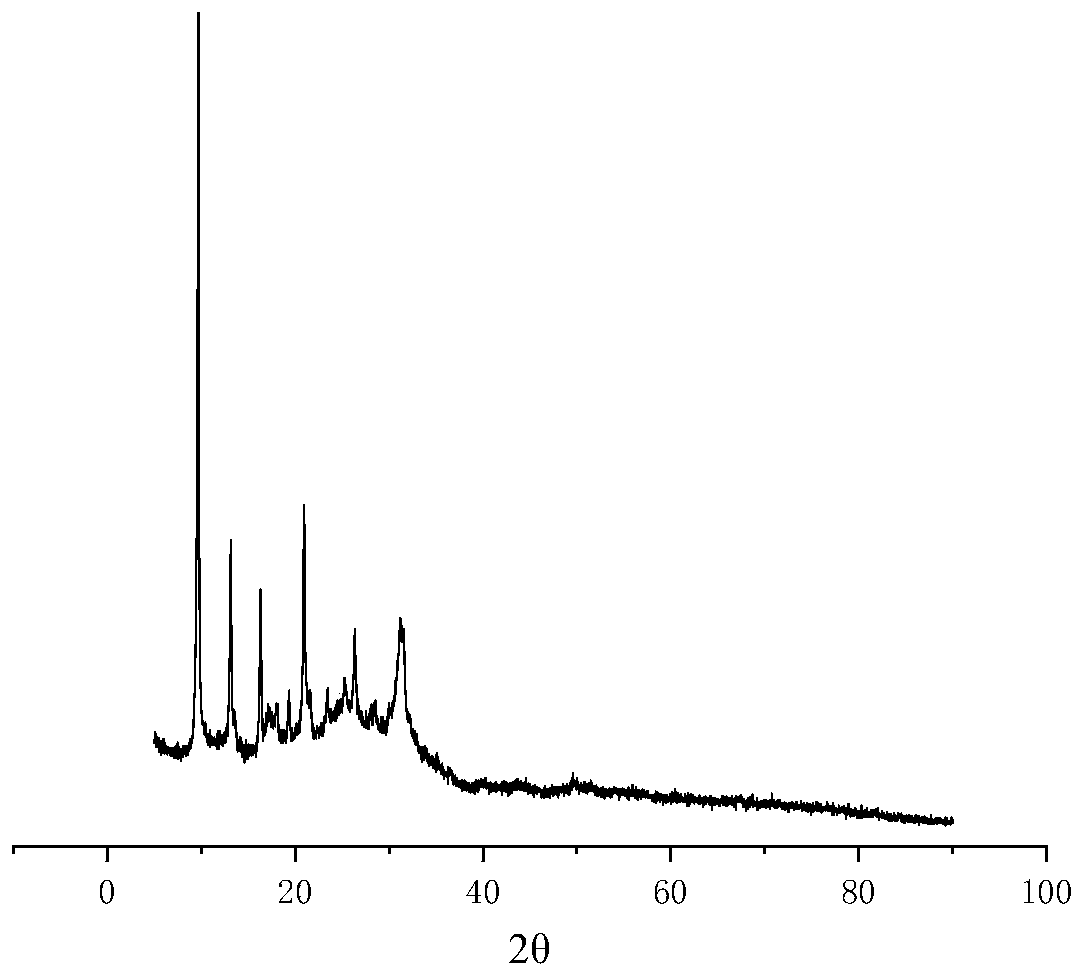

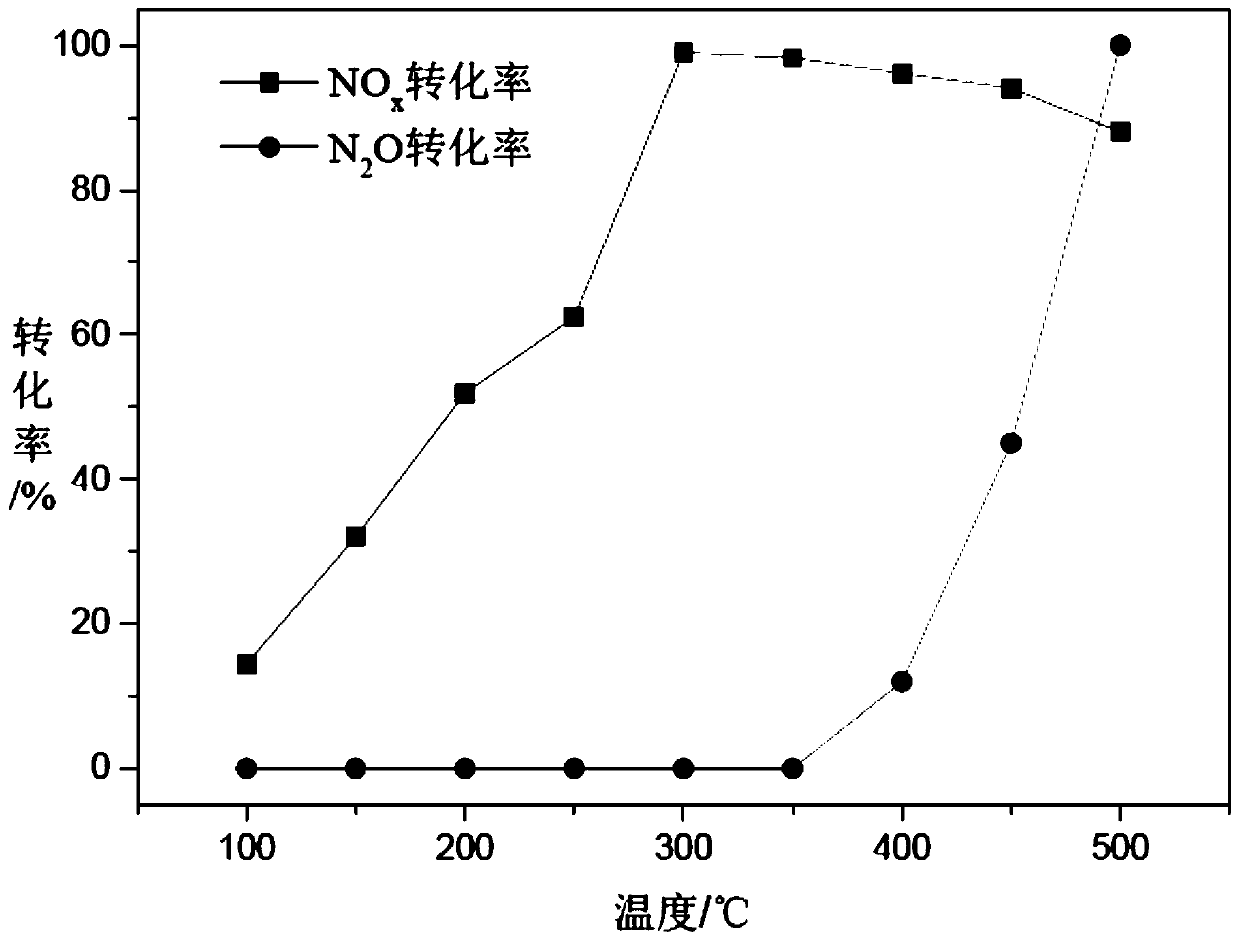

Embodiment 1

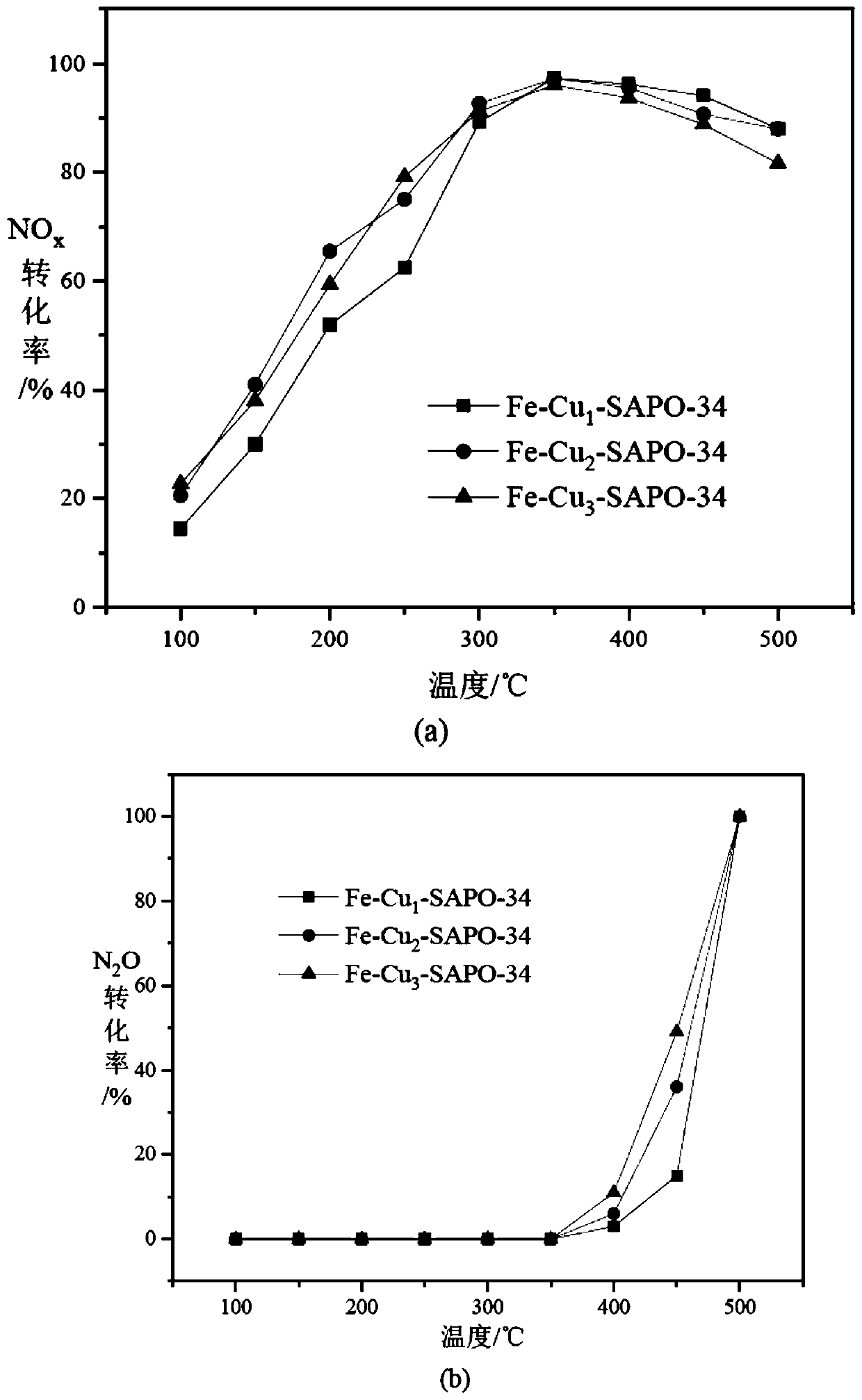

[0025] Embodiment 1: take by weighing 2.2g copper acetate monohydrate (Cu(CH 3 COO) 2 ·H 2 O) Dissolve in 1 g of water, add 0.5 g of tetraethylenepentamine (TEPA), stir at room temperature for 2 h, and obtain copper amine complex (Cu-TEPA). Then weigh 7.5g of phosphoric acid, add 17g of water, mix evenly, pour into the complexed Cu-TEPA solution and stir for 5min. Add 5.6g pseudo-boehmite (70%wt), 5.3g silica sol (30%wt), 5g diethylamine (DEA), 1g seed crystal (H-SAPO-34Si:Al:P=1:1 : 1), stirring at normal temperature for 60min, the crystallization liquid is packed into 100mL to be equipped with in the dynamic reactor of polytetrafluoroethylene liner, and pass into N 2 and N 2 Mixture of O N 2 :N 2 O=9:1, keep the pressure at 1.5Mpa, and crystallize at 150°C for 7 days to obtain a solid phase product. The product was washed and separated by centrifugation at 5000r / min for 3min, dried in an oven at 100°C for 12h, and finally calcined at 550°C for 6h with a heating rate o...

Embodiment 2

[0027] Embodiment 2: take by weighing 4.5g copper acetate monohydrate (Cu(CH 3 COO) 2 ·H 2 O) Dissolve in 2.5 g of water, add 0.5 g of tetraethylenepentamine (TEPA), and stir at room temperature for 2 h to obtain copper amine complex (Cu-TEPA). Then weigh 7.5g of phosphoric acid, add 17g of water, mix evenly, pour into the complexed Cu-TEPA solution and stir for 5min. Add 5.6g pseudo-boehmite (70%wt), 5.3g silica sol (30%wt), 5g diethylamine (DEA), 1g seed crystal (H-SAPO-34Si:Al:P=1:1 : 1), stirring at normal temperature for 60min, the crystallization liquid is packed into 100mL to be equipped with in the dynamic reactor of polytetrafluoroethylene liner, and pass into N 2 and N 2 Mixture of O N 2 :N 2 O=9:1, keep the pressure at 1.5Mpa, and crystallize at 150°C for 7 days to obtain a solid phase product. The product was washed and separated by centrifugation at 5000r / min for 3min, dried in an oven at 100°C for 12h, and finally calcined at 550°C for 6h with a heating ra...

Embodiment 3

[0028] Embodiment 3: take by weighing 9g copper acetate monohydrate (Cu(CH 3 COO) 2 ·H 2 O) Dissolve in 2.5 g of water, add 0.767 g of tetraethylenepentamine (TEPA), and stir at room temperature for 2 h to obtain copper amine complex (Cu-TEPA). Then weigh 6.92g of phosphoric acid, add 15.25g of water, mix well, pour into the complexed Cu-TEPA solution and stir for 5min. Add 5.46g pseudo-boehmite (70%wt), 5.41g silica sol (30%wt), 4.64g diethylamine (DEA), 0.6g seed crystal (H-SAPO-34Si:Al:P=1 :1:1), stirring at room temperature for 30min, the crystallization solution was charged into a 50mL dynamic reactor equipped with a polytetrafluoroethylene liner, and N 2 and N 2 Mixture of O N 2 :N 2 O=9:1, keep the pressure at 1.5Mpa, and crystallize at 150°C for 7 days to obtain a solid phase product. The product was washed and separated by centrifugation at 5000r / min for 3min, dried in an oven at 100°C for 12h, and finally calcined at 550°C for 6h with a heating rate of 2°C / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com