Leaching system for recycling lithium and cobalt from waste lithium cobalt oxide battery and method and application thereof

A lithium cobalt oxide and leaching technology, which is applied in the field of waste resource recycling, can solve the problems of lithium battery recycling companies increasing process costs and increasing the difficulty of subsequent treatment of waste acid, etc., to achieve leaching process optimization, high leaching efficiency, and low raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of leaching method of reclaiming the lithium cobalt in waste lithium cobalt oxide battery comprises the following steps:

[0045] (1) Discharge and disassemble the waste lithium cobaltate battery to obtain the positive electrode of the electrode, and obtain lithium cobaltate powder after crushing and other treatments.

[0046] (2) Make the leaching system of lithium cobalt, i.e. lithium cobalt oxide, polyvinyl chloride and water. Wherein, the volume of water is 210ml, and the mass sum of polyvinyl chloride and lithium cobaltate is 21g.

[0047] (3) After mixing the leaching system made in (2), put it into the reaction kettle and seal it, and continuously feed nitrogen for five minutes. After energized heating to 275°C, the reaction kettle was cooled with cooling water, and after cooling, Li + and Co 3+ mixed solution.

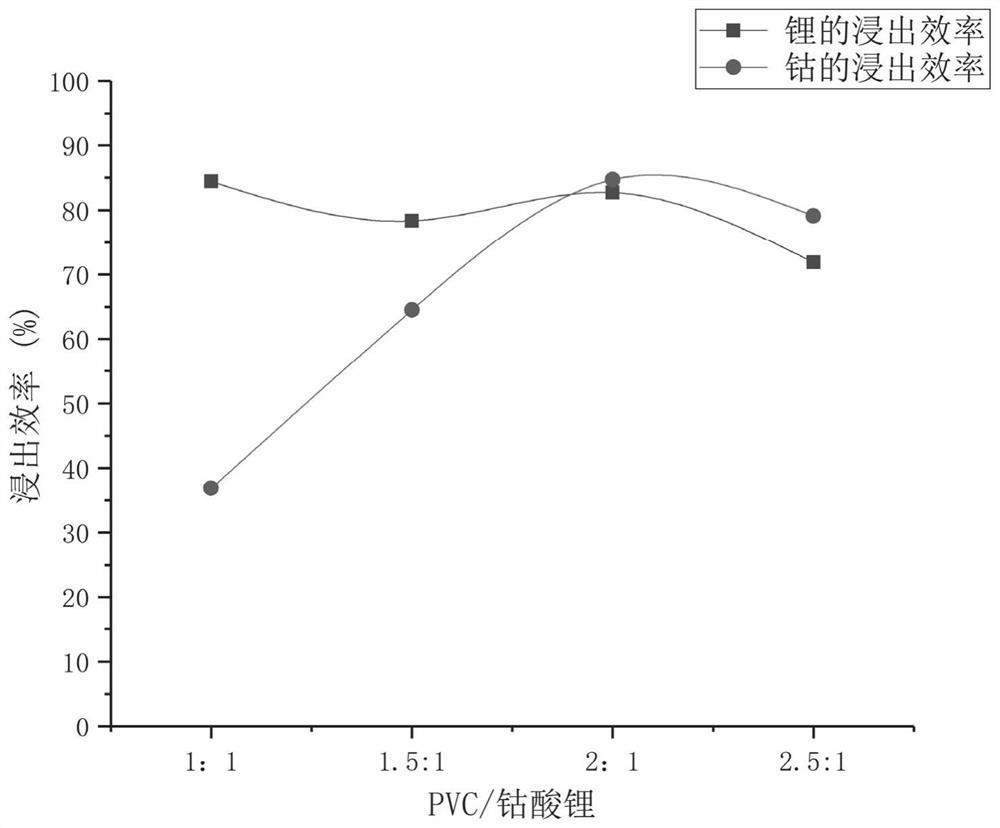

[0048] Experiments were carried out under different mass ratios of polyvinyl chloride and lithium cobaltate, and the Li in the solution after t...

Embodiment 2

[0050] A kind of leaching method of reclaiming the lithium cobalt in waste lithium cobalt oxide battery comprises the following steps:

[0051] (1) Discharge and disassemble the waste lithium cobaltate battery to obtain the positive electrode of the electrode, and obtain lithium cobaltate powder after crushing and other treatments.

[0052] (2) Make the leaching system of lithium cobalt, i.e. lithium cobalt oxide, polyvinyl chloride and water. Among them, the volume of water is 210ml, the mass of polyvinyl chloride is 14g, and the mass of lithium cobaltate is 7g.

[0053] (3) After mixing the leaching system made in (2), put it into the reaction kettle and seal it, and continuously feed nitrogen for five minutes. After electrified heating to different temperatures, the reaction kettle is cooled with cooling water, and after cooling, a mixture containing Li is obtained. + and Co 3+ mixed solution.

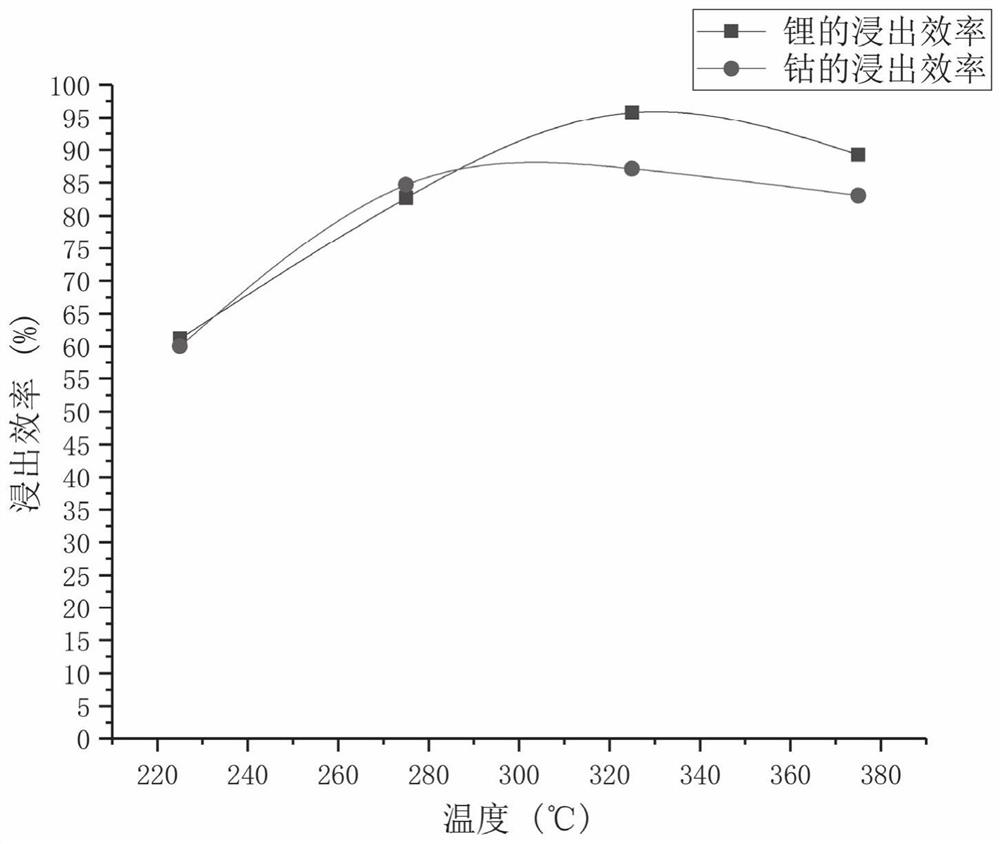

[0054] Experiments were carried out at different reaction temperatures, and...

Embodiment 3

[0056] A method for leaching lithium cobalt in reclaiming waste lithium cobalt oxide batteries, comprising the following steps:

[0057] (1) Discharge and disassemble the waste lithium cobaltate battery to obtain the positive electrode of the electrode, and obtain lithium cobaltate powder after crushing and other treatments.

[0058] (2) Make the leaching system of lithium cobalt, i.e. lithium cobalt oxide, polyvinyl chloride and water. Among them, the volume of water is 210ml, the mass of polyvinyl chloride is 14g, and the mass of lithium cobaltate is 7g.

[0059] (3) After mixing the leaching system made in (2), put it into the reaction kettle and seal it, and continuously feed nitrogen for five minutes. After heating to 325°C with electricity, keep it warm for a period of time, then cool the reaction kettle with cooling water, and after cooling, get a solution containing Li + and Co 3+ mixed solution.

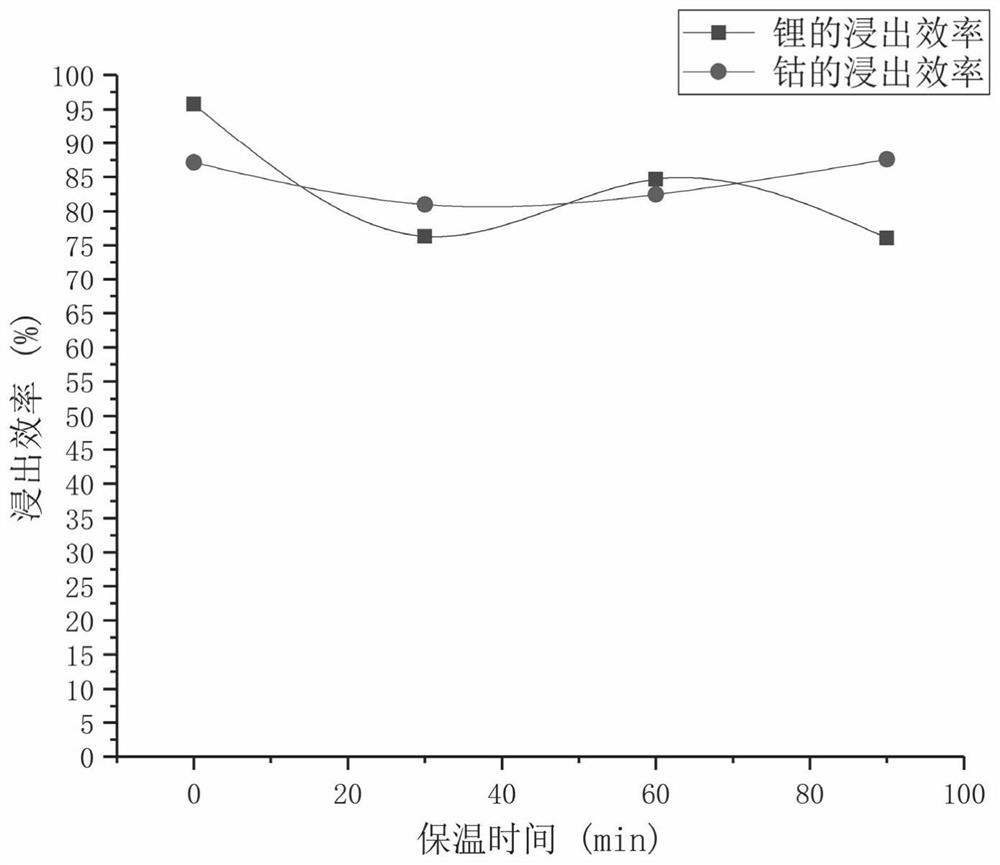

[0060] Experiments were carried out at different holding times, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com