Process for preparing electrolytic copper foil in short range by utilizing copper oxide ore

A technology of copper oxide ore and electrolytic copper foil, which is applied in the field of electrolytic copper foil, can solve the problems of not meeting the copper-acid ratio requirements of copper foil, complex production process, environmental pollution of waste acid, etc., to achieve saving power consumption, good social benefits, The effect of saving manufacturing cost and capital occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

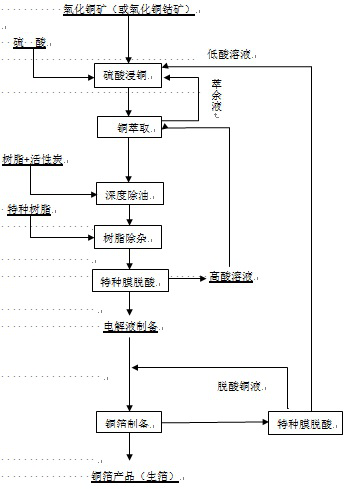

[0007] Such as figure 1 As shown, the present invention comprises the following steps: (1), sulfuric acid copper leaching: copper oxide ore and sulfuric acid are mixed and soaked for a period of time to obtain a leachate; (2) copper extraction: the leachate is subjected to copper extraction to obtain an extract and a raffinate, and the extraction The remaining liquid is returned to step (1); (3), deep degreasing: use resin + activated carbon to carry out deep degreasing of the extract; (4), resin decontamination: use the extract after step (3) deep degreasing Special resin for impurity removal; (5), special membrane deacidification: deacidify the extract after step (4) resin removal with special membrane to obtain copper sulfate crystals and high-acid solution, and high-acid solution returns to step (2) (6), preparation of electrolyte: configure copper sulfate crystals into electrolyte; (7), preparation of copper foil: prepare copper foil with electrolyte, obtain raw foil and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com