Technique for short-range preparation of electrolytic copper foil from copper sulfate solution in wet smelting process

A technology of copper sulfate solution and electrolytic copper foil, which is applied in the field of electrolytic copper foil, can solve the problems of not meeting the copper-acid ratio requirements of copper foil, environmental pollution of waste acid, complex production process, etc., and achieve saving power consumption, good social benefits, The effect of shortening the industrial process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

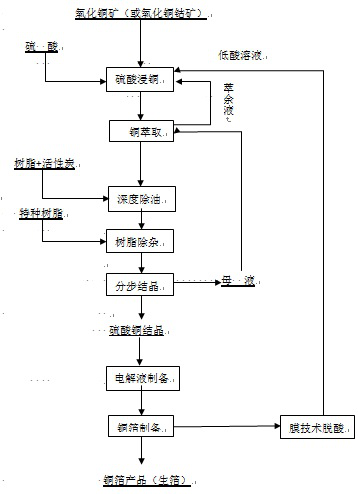

[0007] Such as figure 1 As shown, the present invention comprises the following steps: (1), sulfuric acid copper leaching: copper oxide ore and sulfuric acid are mixed and soaked for a period of time to obtain a leachate; (2) copper extraction: the leachate is subjected to copper extraction to obtain an extract and a raffinate, and the extraction The remaining liquid is returned to step (1); (3), deep degreasing: use resin + activated carbon to carry out deep degreasing of the extract; (4), resin decontamination: use the extract after step (3) deep degreasing Special resins are used for impurity removal; (5), fractional crystallization: the extract solution after step (4) resin impurity removal is fractionally crystallized to obtain copper sulfate crystals and mother liquor, and the mother liquor is returned to step (2); (6), electrolyte solution Preparation: Prepare copper sulfate crystals into electrolyte; (7) Copper foil preparation: prepare copper foil with electrolyte to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com