Automatic installation and control device of engine piston and design method of automatic installation and control device

An automatic installation and control device technology, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems that affect installation accuracy, low efficiency, fatigue work, etc., and achieve the effects of labor saving, low energy consumption and perfect functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

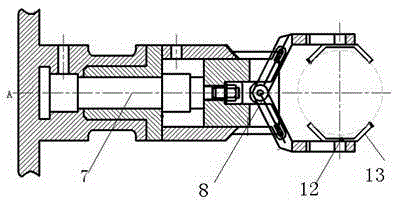

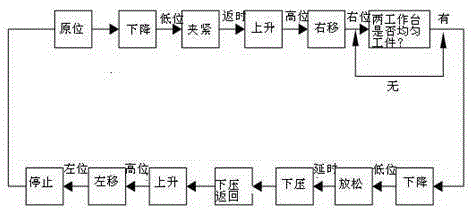

[0020] Embodiment of the present invention: a design method for automatic engine piston installation and control device, characterized in that: the method uses the control system to drive the actuator to complete the grasping and spatial position positioning of the piston, and the drive system is used after the belt positioning is completed Push the positioned piston to the designated position of the mechanical equipment.

[0021] Among them, the control system is implemented by PLC, and the actuator is implemented by a mechanical gripper. The mechanical gripper is controlled by the PLC to complete the grasping of the piston and the positioning of the spatial position. The dynamic system adopts the pneumatic drive technology. Right above, push the piston to the specified position of the mechanical equipment after realizing the positioning with the piston.

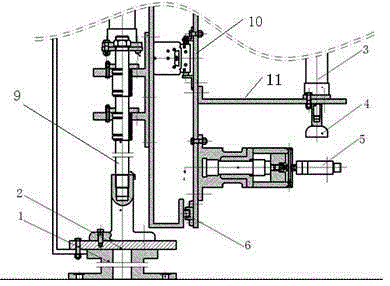

[0022] A kind of engine piston automatic installation and control device required according to the above method, as shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com