Worktable device used for processing board, capable of decreasing noise and provided with rolling device and application method thereof

A rolling device and plate processing technology, applied in the field of plate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

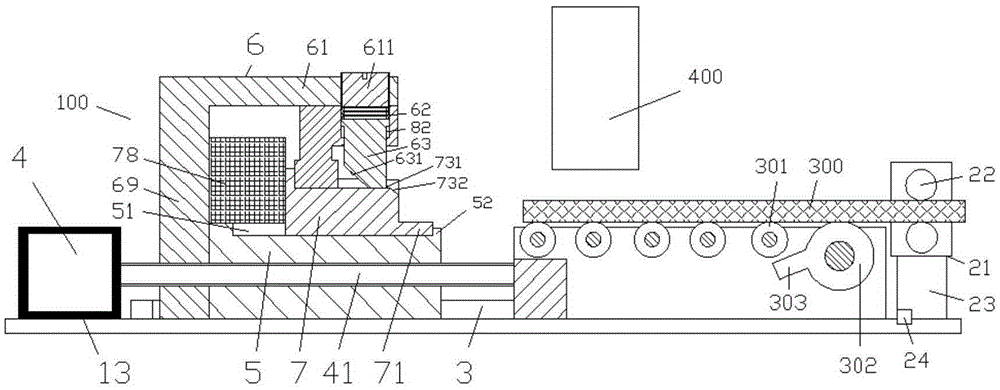

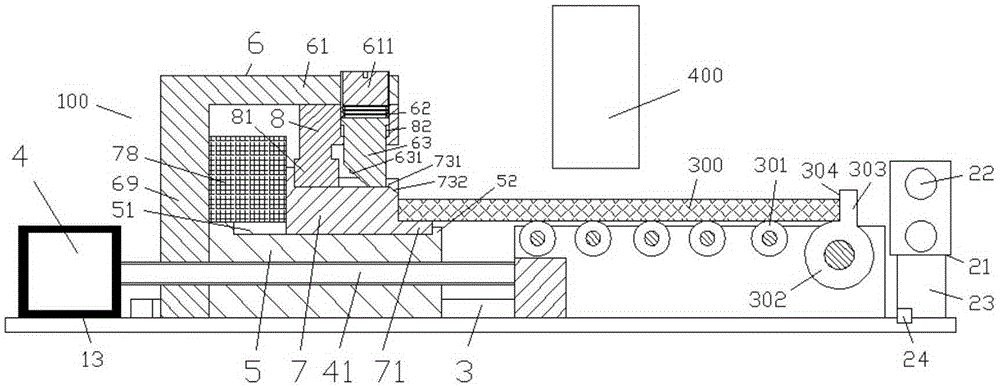

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] According to an embodiment, a workbench device capable of reducing noise and equipped with a rolling device for plate processing includes a transmission support device fixedly connected to the frame, a locking drive motor 4 fixedly connected to the frame, and The drive screw 41 that is powered by the locking drive motor 4 and the locking assembly 100 that is driven by the screw thread on the drive screw 41, the outer periphery of the lock drive motor 4 is provided with a soundproof box 13 to reduce the locking drive. The noise generated by the motor 4 during operation, and the soundproof box 13 is made of metal material can also play a role in cooling, wherein the locking assembly 100 is used to lock the plate 300 under the drive of the locking drive motor 4 Positioning and locking are performed close to the side of the locking assembly 100; the conveying support device is located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com