Novel hydraulic mount

A hydraulic mount, a new type of technology, applied in the field of auto parts, can solve problems such as complex structure, high cost, and failure to meet shock absorption requirements, and achieve the effect of simple overall structure, stable performance, and reasonable design of vibration isolation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

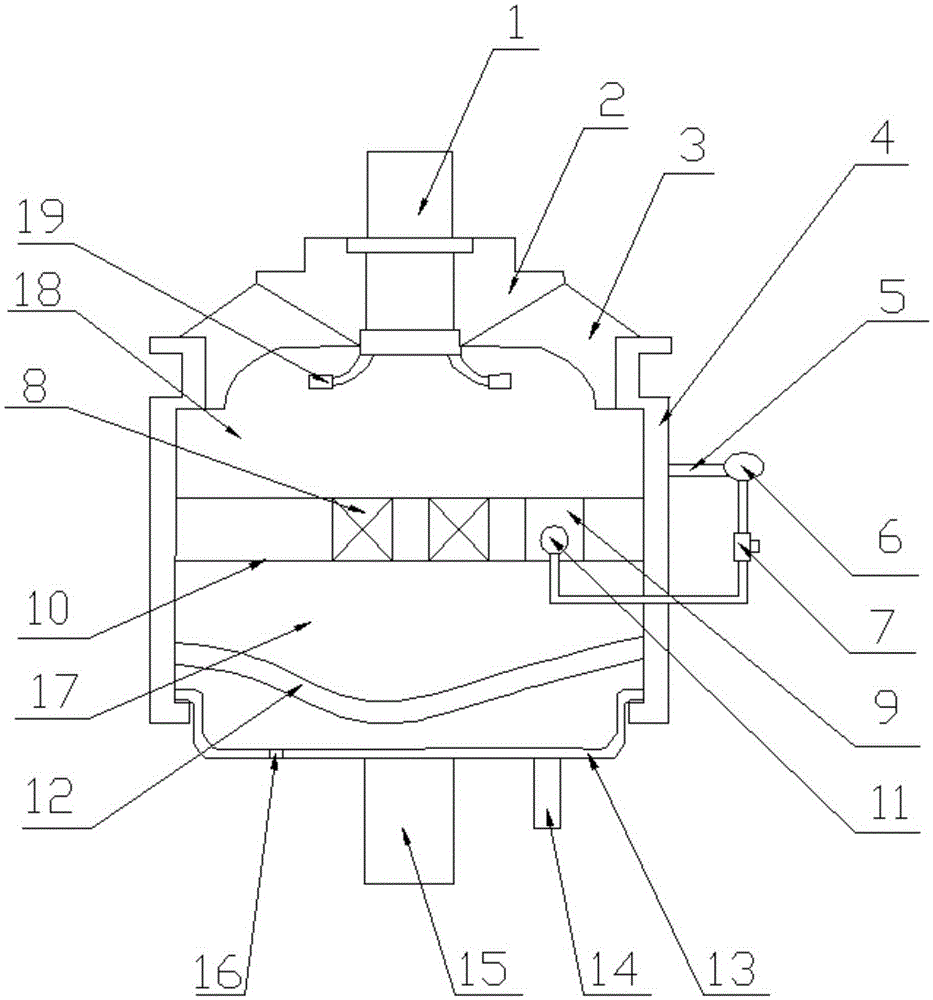

[0019] New hydraulic mounts, such as figure 1 As shown, it includes a rubber main spring 3, a housing 4 and a bottom film 12. The rubber main spring 3, the housing 4 and the bottom film 12 form a cavity filled with magnetorheological fluid, and a vibration isolation mechanism 10 is arranged in the cavity. The vibration mechanism 10 divides the cavity into an upper liquid chamber 18 and a lower liquid chamber 17. The vibration isolation mechanism 10 is provided with a ring coil 8, and the two ends of the ring coil 8 are connected to a power supply. The vibration isolation mechanism 10 is provided with an inertia channel 9. Magneto-rheological fluid is a suspension composed of tiny soft magnetic particles with high magnetic permeability and low hysteresis and a non-magnetic liquid. This suspension exhibits low-viscosity Newtonian fluid characteristics under zero magnetic field conditions; Under the action of a strong magnetic field, it exhibits high viscosity and low flow charac...

Embodiment 2

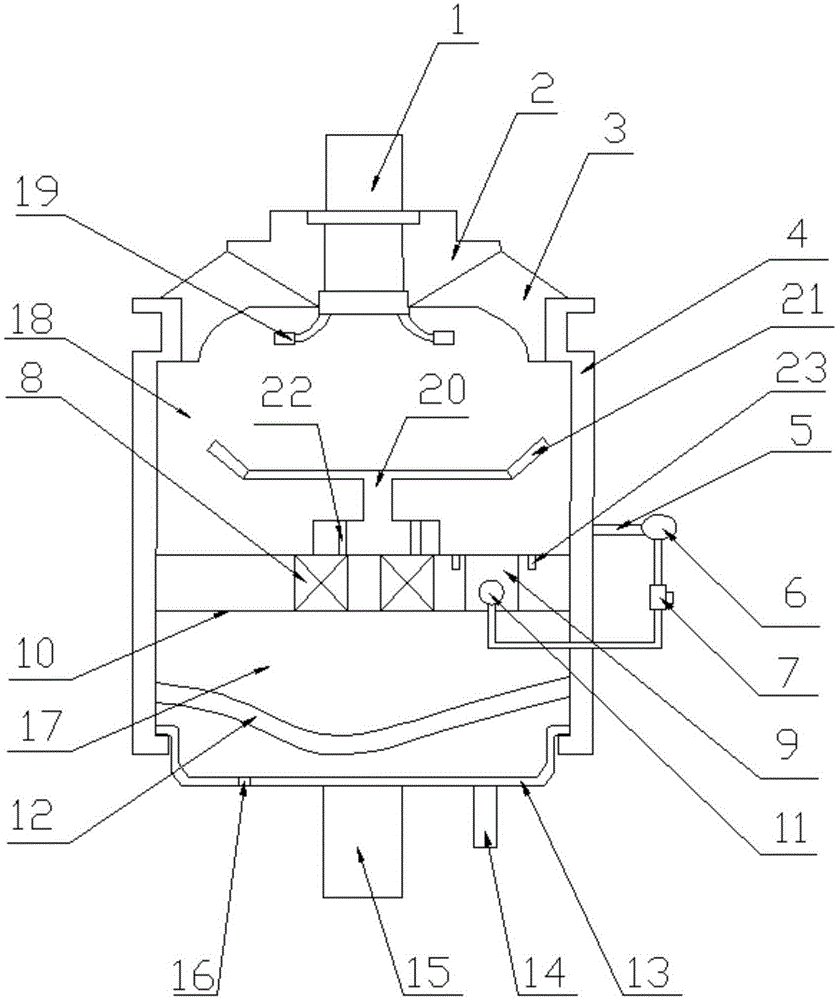

[0027] With embodiment 1, the difference is as figure 2 As shown, the isolation plate 20 is provided on the vibration isolation mechanism 10, and the two ends of the isolation plate 20 are provided with sloping plates 21. The sloping plates 21 are arranged obliquely upward. When the upper connecting bolt 1 is squeezed, the liquid below the upper connecting bolt 1 The deformation is the largest, and the liquid flows to the inertial channel 9 along the isolation plate 20, the isolation plate 20 changes the flow direction of the liquid, increases the liquid flow distance, and consumes energy when the liquid flows, thereby increasing the damping of the hydraulic mount; the inclined plate 21 and the isolation plate 21 The space of the vibration mechanism 10 is larger than the space between the isolation plate 20 and the vibration isolation mechanism 10. Since the liquid flows from the large space to the small space, the liquid is squeezed and the damping becomes larger, thereby inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com