Colorful FDM 3D printing material and preparation method thereof

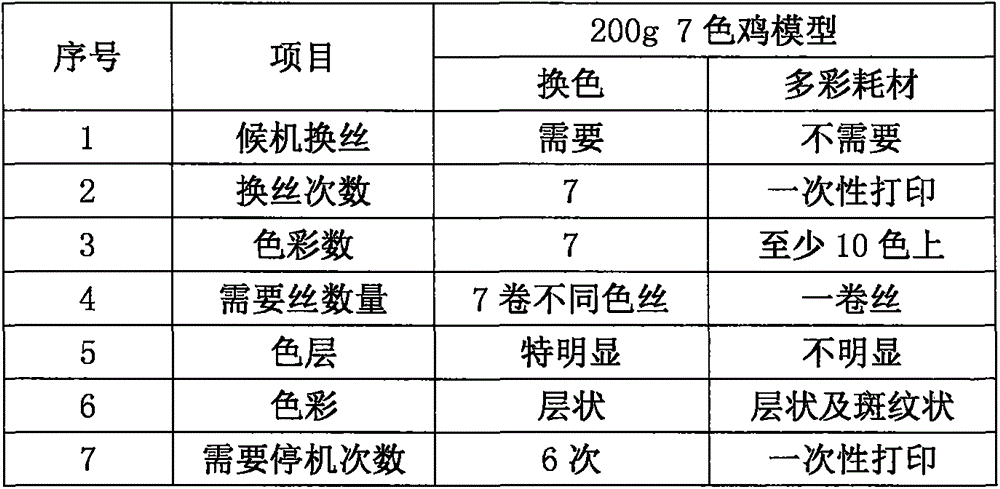

A technology of colorful and printing materials, applied in the field of 3D printing, can solve problems such as complicated operation, printing failure, and easy misalignment of printing positions, and achieve the effects of easy use, low machine failure rate, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh in proportion: 100 parts of PLA, 10100.5 parts of antioxidant, 0.5 parts of plasticizer DOP, 5 parts of toughening agent PTW, 5 parts of compatibilizer polylactic acid grafted maleic anhydride and 0-10 parts of rheology modifier , mixed evenly, and then dried at 60-65 ° C for 4 hours; then the dried pellets are added to the barrel of the single-screw extruder, extruded and formed, and water-cooled after the exit die until the shape is set; the uniform pulling force is selected for traction , uniform 3D printing filaments with a diameter of 1.75 mm and a diameter of 3.00 mm can be obtained.

[0045] coloring. Adopt mechanical control, intermittent coloring. Swap tinting yellow, red, and blue, and control the tinting gap.

[0046] In the setting process, the length of coloring yellow is 10cm; the gap is 3cm; the coloring red is 10cm, the gap is 3cm, and the blue is 10cm. Alternate coloring and gaps in sequence.

[0047] (4) Air-cooled, wound into rolls:

[0048...

Embodiment 2

[0057] Weigh in proportion: 100 parts of PLA, 10100.5 parts of antioxidant, 0.5 parts of plasticizer DOP, 10 parts of toughening agent EVA, 5 parts of polylactic acid grafted maleic anhydride, 0-10 parts of rheology modifier, mix well , and then dried at 60-65 °C for 4 hours; then add the dried pellets into the barrel of the single-screw extruder, extrude and form, and after the exit die, use water cooling until the shape is set; select the uniform pulling force to obtain the diameter Uniform 3D printing filament of 1.75mm and 3.00mm diameter. coloring. Adopt mechanical control, intermittent coloring. Swap tinting yellow, red, and blue, and control the tinting gap.

[0058] In the setting process, the length of the coloring yellow is 3cm; the gap is 5cm; the coloring red is 3cm, the gap is 5cm, and the blue is 3cm. Alternate coloring and gaps in sequence.

[0059](4) Air-cooled, wound into rolls:

[0060] The printed model is colorful, beautiful, and the layering is obvio...

Embodiment 3

[0062] Weigh in proportion: 100 parts of PLA, 10100.5 parts of antioxidant, 0.5 part of plasticizer DOP, 5 parts of toughening agent EVA, 0-10 parts of rheology modifier, and 5 parts of silicon micropowder. Mix evenly, then dry at 60-65°C for 4 hours; then add the dried pellets into the barrel of the twin-screw extruder, and extrude and granulate. Then, the pellets are dried, extruded by a single-screw extruder, and water-cooled after exiting the die until the shape is set; uniform 3D printing filaments with a diameter of 1.75mm and a diameter of 3.00mm can be obtained by selecting uniform pulling force. This material was then tested for printing. coloring. Adopt mechanical control, intermittent coloring. Swap tinting yellow, red, and blue, and control the tinting gap.

[0063] In the setting process, the length of coloring yellow is 5cm; the gap is 1cm; the coloring red is 5cm, the gap is 3cm, and the blue is 10cm. Alternate coloring and gaps in sequence. Keep the shadin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com