Oxyhydrogen machine and oxyhydrogen generating method

A technology of hydrogen oxygen machine and fuselage, which is applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of increased cost and difficulty in assembly, and achieve the effects of convenient assembly, increased gas production, and excellent promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

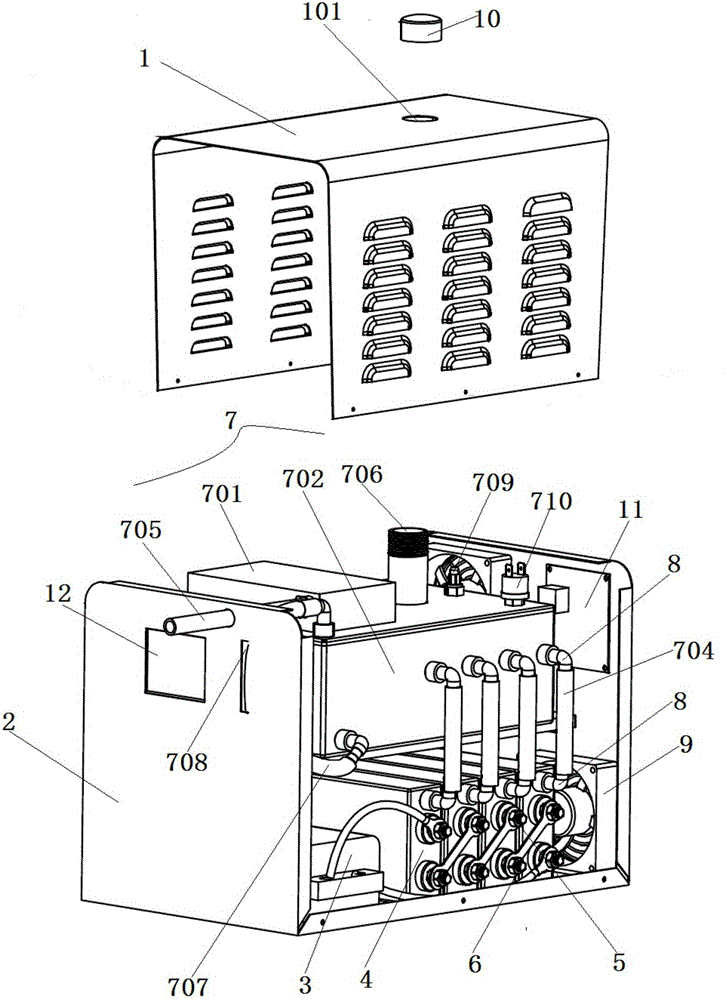

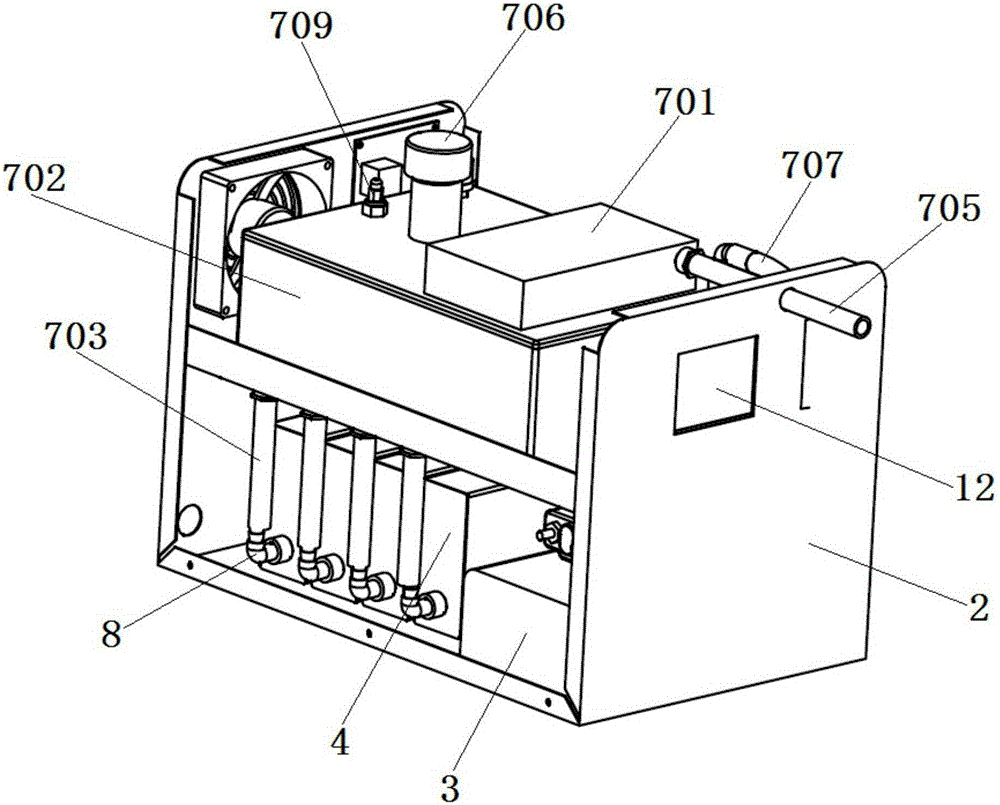

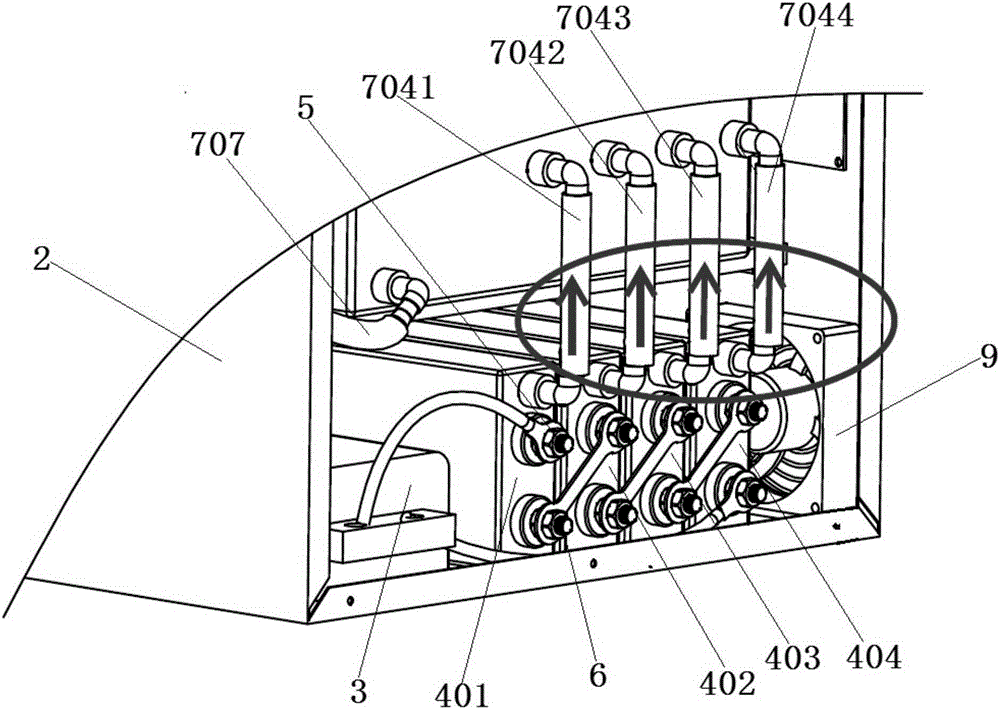

[0066] In the first aspect, the embodiment of the present invention provides an oxygen hydrogen machine, as attached figure 1 As shown, the hydrogen oxygen machine includes: an upper casing 1, a main body 2 matched with the upper casing 1, a power supply 3 arranged in the main body 2, an electrolyzer assembly 4, a steam-water separation assembly 7, a cooling assembly and a control Assemblies, the steam-water separation assembly 7 is located above the electrolyzer assembly 4. Wherein, the electrolytic cell assembly 4 includes a plurality of electrolytic cells arranged vertically in sequence, and the plurality of electrolytic cells are connected in series and electrically connected to the power supply 3 . For example, the electrolysis c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com