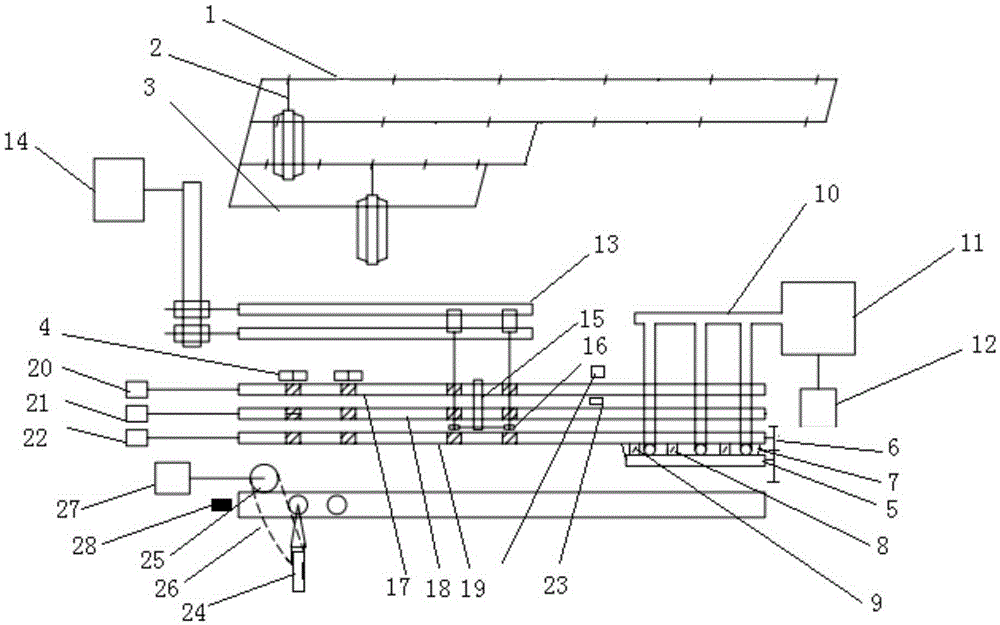

Multifunctional spinning frame

A spinning frame and multi-functional technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of high cost, difficulty in multi-functional yarn simulation training, and new multi-functional varieties. Issues such as large development investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

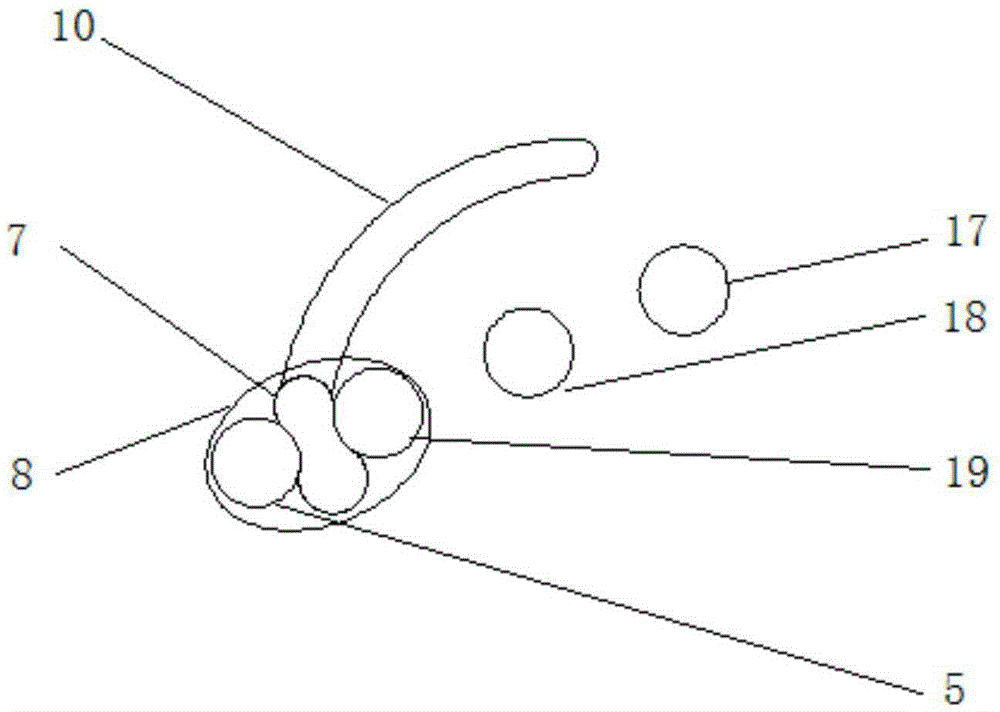

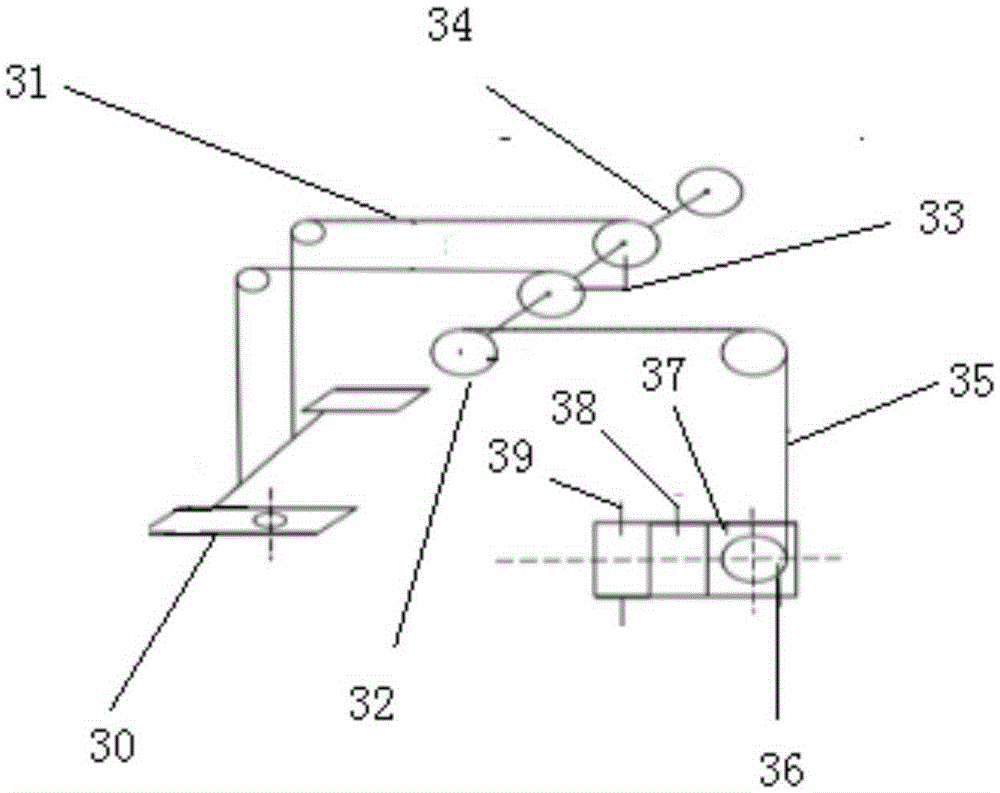

Method used

Image

Examples

Embodiment 1

[0029] Develop 14.6tex65 / 35 polyester / wood pulp fiber siro spinning knitting yarn, select polyester / wood pulp fiber 65 / 35 blended roving with a basis weight of 3.1g / 10m and a roving twist coefficient of 72, and put the transformed spinning frame into the mechanical In the parameter adjustment interface, set the distance between the bell mouth to 4mm, the gap between the jaws to 3mm, the roller gauge to 18mm*34mm, and the yarn twist coefficient to 330, and place the two roving bobbins on the inner and outer roving creels respectively. , bypassing the yarn guide rod, feed into the double bell mouth respectively, start the siro spinning function, and the spinning frame can produce 14.5tex65 / 35 polyester / wood pulp fiber siro spun knitting yarn.

Embodiment 2

[0031] Develop 7.3tex65 / 35 cotton / Tencel compact blended yarn, select the roving with 30% Tencel fiber and 70% cotton fiber obtained through sliver blending, and enter the compact spinning parameters of the transformed spinning frame Adjust the interface, adjust the compact spinning air negative pressure value to 1300 Pa, enter the mechanical parameter adjustment interface, adjust the total draft ratio of the spinning frame to 44.18, the spinning twist to 131.9 twists / 10m, the spindle speed to 15000r / min, and the roller gauge to be designed as 18mm*34mm, place the roving bobbin on the roving frame in the compact spinning area, bypass the yarn guide rod, feed into the bell mouth, enter the drafting area and twisting winding area, start the compact spinning function, and the spinning frame will It can produce 7.3tex65 / 35 cotton / tencel compact blended yarn.

Embodiment 3

[0033] Develop aloe fiber / spun silk / cotton 40 / 40 / 20 blended roving as outsourcing fiber and spandex as core yarn to spin 40tex (44.4dtex) multi-component spandex core-spun yarn. Core yarn parameter adjustment interface (the same adjustment interface as compact spinning), input spandex linear density as 44.4dex, spandex yarn pre-drawing 4.0 times, twist design as 60 twist / 10m, core yarn feeding guide roller line speed as 22.3m / min, spindle speed 12600r / min, rear area draft 1.20 times, roller center distance 18mm*34mm, place the roving tube on the roving frame in the compact spinning area, bypass the yarn guide rod, feed into the bell mouth, and enter the drafting process zone and twisting winding zone, start the core-spun yarn spinning function, and the spinning frame can produce 40tex (44.4dtex) aloe fiber spun silk cotton spandex core-spun yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com