Detecting method for pile-bottom supporting layer of mechanical pore-forming concrete filling pile

A technology of mechanical hole forming and detection method, which is applied in the test of infrastructure, construction, infrastructure engineering, etc., can solve the problems of high survey cost, long survey time, uncertainty, etc., and achieves reduction of survey cost, detection cost, Detecting fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

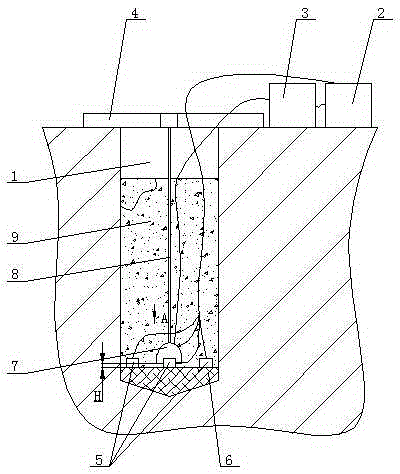

[0027] A method for detecting the bearing layer at the bottom of a mechanical hole-forming concrete pouring pile of the present invention comprises the following steps:

[0028] ① Place several double geophones evenly along the circumferential direction at the bottom of the large-diameter pile hole;

[0029] ② Use the electric spark source to artificially excite the elastic wave at the center of the bottom of the pile hole;

[0030] ③Use the shallow seismograph to record the reflected waves received by the dual geophones at the bottom of the pile hole;

[0031] ④ Analyze and study these waveform records to determine whether there are unfavorable geological conditions such as caves, troughs or broken zones within a certain range at the bottom of the pile hole.

[0032] A further scheme provided by the present invention is: the steps are as follows:

[0033] ①Drilling pile holes;

[0034] ② Place the double geophones from the edge of the pile hole to the bottom of the pile ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com