Novel turbine blade

A technology for steam turbine blades and blades, which is applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problems that blade radiation lines are not on the same plane, cannot guarantee accuracy, and affect blade life, so as to prevent water corrosion and Lateral movement, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

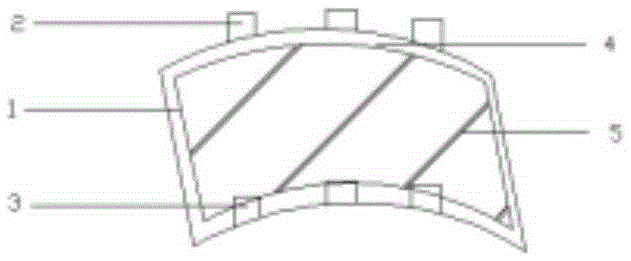

[0017] The blade 1 is annularly wound on the rotor, and the blade shroud 4 is located on the blade. The inner radial surface of the blade shroud 4 is provided with a groove 3, and the outer radial surface of the blade shroud body is provided with a protruding tooth 2 that can fit into the groove 3 to realize adjacent The positioning of the blade crown, while avoiding the lateral movement of the blade, improves the accuracy. The surface of the blade 1 is covered with a layer of ceramic material 5. The manufacturing steps of the ceramic material 5 are: firstly polish the blade surface, and evenly cover the blade surface with a special Ceramic soil, sent to the kiln for firing.

[0018] Finally, it should be noted that: the above embodiments are only used to illustrate the present invention and are not intended to limit the technical solutions described in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com