Pre-protecting system for slipping of wind driven generator coupler and detection control method

A technology of wind turbines and couplings, applied in the control of wind turbines, monitoring of wind turbines, wind turbines, etc., can solve the problems of rising spare parts cost, frequent replacement, time-consuming and laborious replacement, etc., to achieve low loss and prevent slippage damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

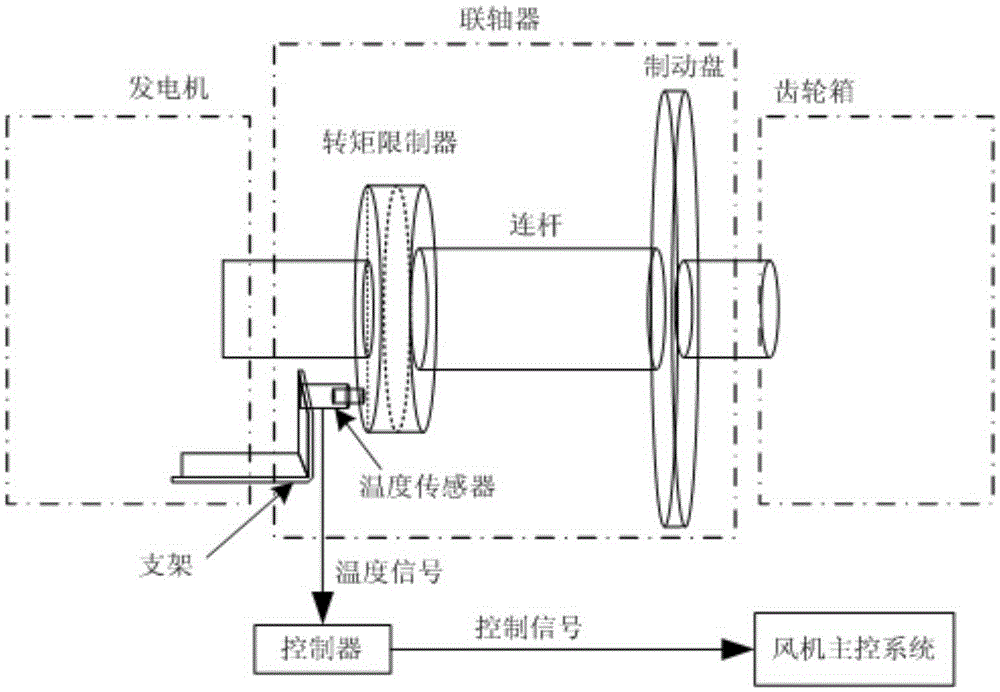

[0024] refer to figure 1 , is a structural schematic diagram of the present invention; the pre-protection system of the wind turbine coupling slipping, the wind turbine includes a gearbox output shaft, a coupling and a generator main shaft, and the coupling is connected to the gear The output shaft of the box and the main shaft of the generator, the coupling includes a torque limiter connected with the main shaft of the generator, and a brake disc connected with the output shaft of the gearbox, and the torque limiter is connected with the brake disc through a connecting rod The generator is connected to a temperature sensor through a bracket, and the temperature sensor communicates with the controller; the controller communicates with the main control system of the fan; the temperature sensor is preferably an infrared temperature sensor, which is used to monitor the current temperature of the coupling to obtain the current temperature, and send the obtained current temperature...

Embodiment 2

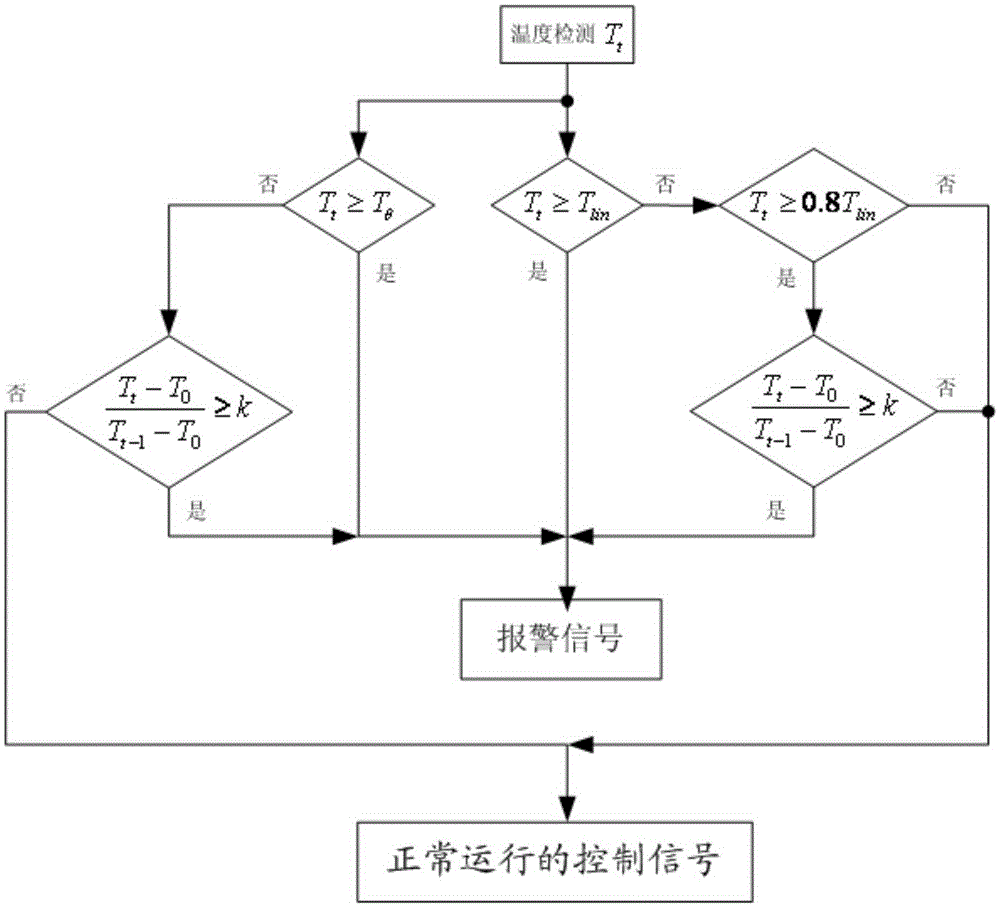

[0026] Please refer to figure 2 , the present invention also provides a coupling slip detection control method, the method includes the following steps:

[0027] Step 1: Obtain the initial temperature value T of the coupling 0 , the initial temperature value of the coupling is the ambient temperature, and start the wind turbine;

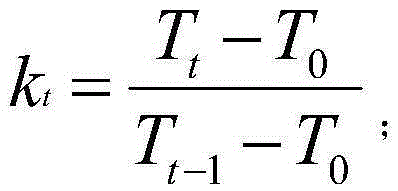

[0028] Step 2: After the wind turbine is started, obtain the temperature value T of the coupling at the current time t t And the temperature value T at time t-1 t-1 , and calculate the temperature rise slope k from time t-1 to time t t ,in, k t = T t - T 0 T t - 1 - T 0 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com