Decentralized cup-shaped cylinder and swash plate axial piston pump supported by rolling bearings

A rolling bearing, decentralized technology, applied in the components of pumping devices for elastic fluids, multi-cylinder pumps, variable displacement pump components, etc., can solve the problems of slipper failure, reduced pump reliability, slipper wear and other issues , to reduce the moment of inertia, improve reliability and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

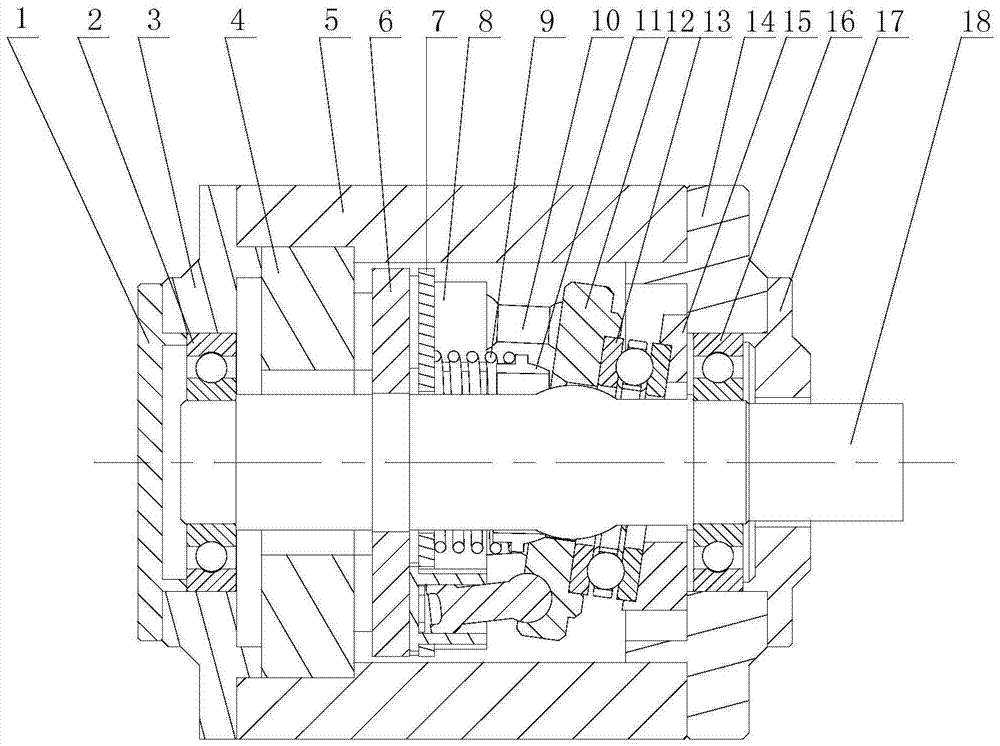

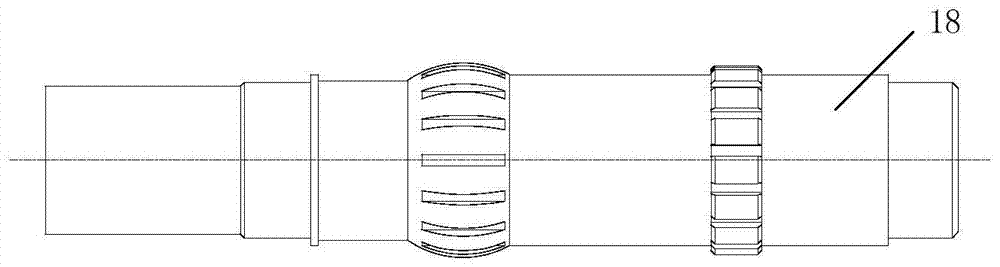

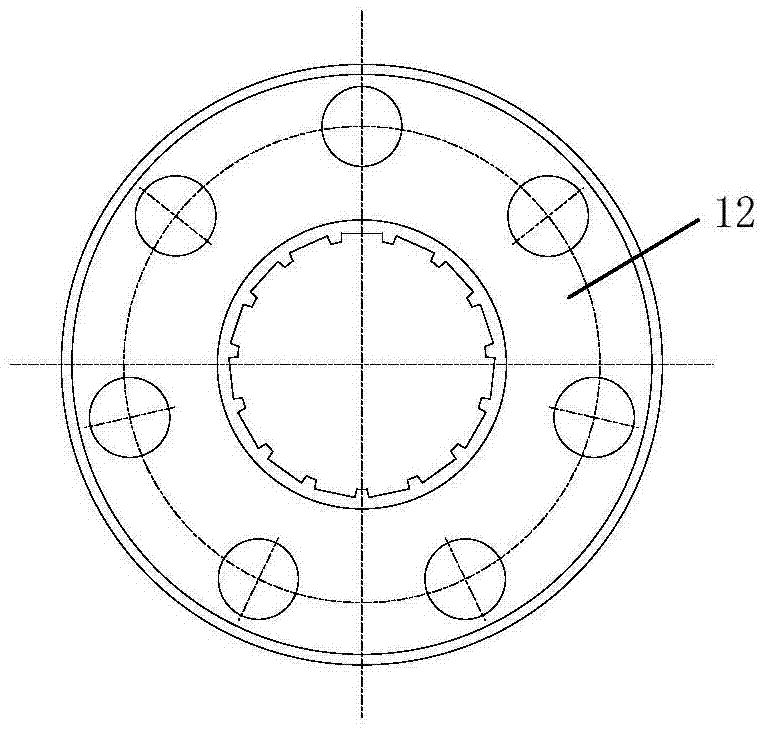

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a swash plate axial piston pump supported by a decentralized cup-shaped cylinder and rolling bearings, including a drive shaft 18, the left and right ends of the drive shaft 18 are installed on the left end cover 3 through the first bearing 2 and the second bearing 16 respectively And on the right end cap 14, the left end cap 3, the right end cap 14 and the shell 5 are screwed together, and the first sealing end cap 1 and the second sealing end cap 17 are respectively installed on the outside of the left end cap 3 and the right end cap 14, and the driving The right side of the middle part of the shaft 18 is connected with the swash plate 12 through a drum-shaped spline, the left end surface of the swash plate 12 is connected with several plungers 10 through a ball joint, the right end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com