Self-adaptive valve bank for rock drilling machine

A rock drilling rig, self-adaptive technology, applied in mechanical equipment, servo motor components, fluid pressure actuating devices, etc., can solve the problems of affecting the hole forming effect, user loss, slow return, etc., to improve the lifting response control features, the effect of reducing the time to rework, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

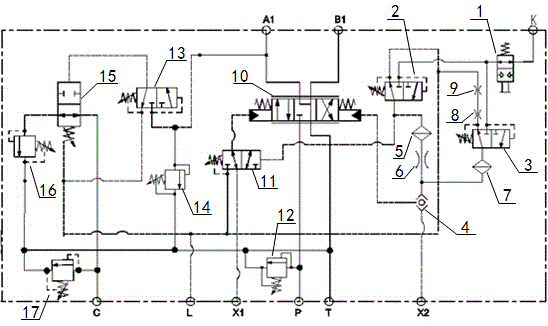

[0018] Such as figure 1 In the self-adaptive valve group of the rock drilling rig shown, the oil inlet of the manual switch valve 1 communicates with the rotary pressure signal port K, and the pressure oil enters from the rotary pressure signal port K of the valve group, and passes through the manual Switch valve 1 and then flow into the first sequence valve 2 and the second sequence valve 3 of the valve group. The anti-seize function of the present invention can be closed by the manual switch valve 1 . When closed, the maximum rotational pressure is limited to the maximum pressure set by the system.

[0019] The oil inlet port of the first sequence valve 2 communicates with the oil outlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com