Suspension oil cylinder and crane

A technology for suspending oil cylinders and cylinder barrels, which is applied in the direction of load suspension components, transportation and packaging, fluid pressure actuation devices, etc., which can solve problems such as poor adaptability and achieve good sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

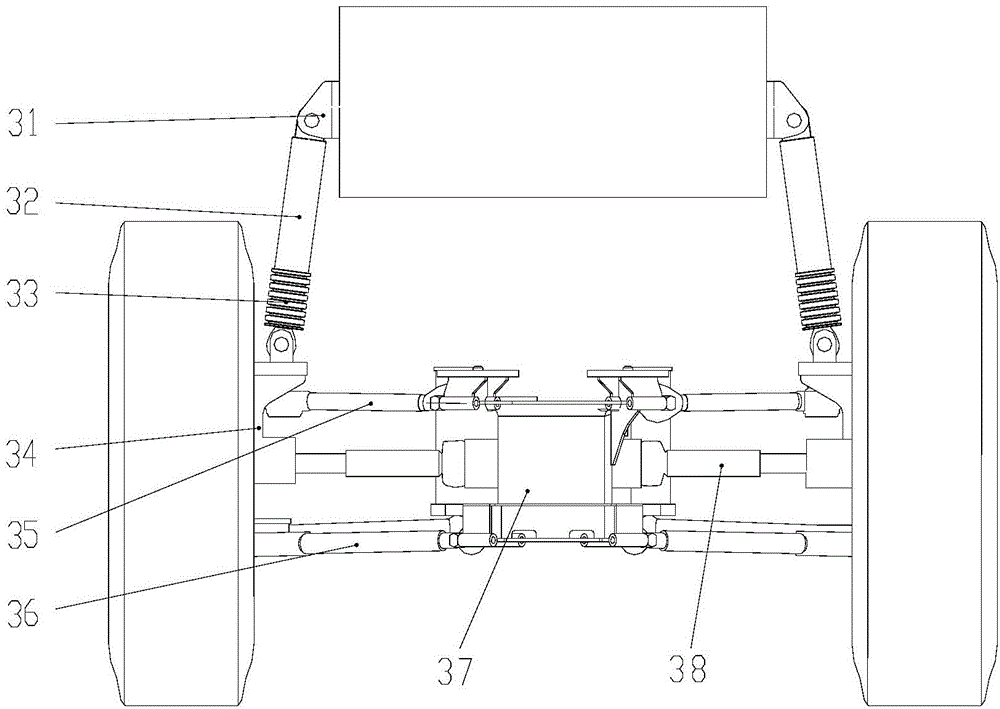

[0064] Such as Figure 6 ~ Figure 7 As shown, the suspension oil cylinder provided by the embodiment of the present invention includes a cylinder barrel 59, a piston rod 512 and a shock absorber, and the shock absorber includes an anti-falling body (preferably an end cover 52, the bottom surface or the side surface of the end cover 52 A layer of elastic material can also be provided or coated, and the elastic material can be rubber), connecting seat 53, flexible pad 54 (preferably rubber pad) and ball joint bearing inner ring 55, wherein: connecting seat 53 forms the ball joint bearing outer ring. A piston 515 can be provided at the end of the piston rod 512 , for example, the piston 515 can be provided at the end of the piston rod 512 .

[0065] The connection seat 53 , the flexible pad 54 and the inner ring 55 of the ball joint bearing are all provided with connection through holes. The anti-off body abuts against the part of the connecting seat 53 away from the cylinder ba...

Embodiment 2

[0083] Such as Figure 8 with Figure 9 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that in this embodiment, the anti-detachment body (preferably end cap 52) can be connected through a detachable connection structure (preferably with such as Image 6 The anti-loosening bolts 51 shown in the same structure or similar) are connected with the piston rod 64, the piston rod 64 is fixedly connected with the inner protective shell 62, and the cylinder barrel 63 is fixedly connected with the outer protective shell 61. The inner protective shell 62 is sheathed outside the cylinder 63 , and the cylinder 63 is interposed between the inner protective shell 62 and the piston 65 at the end of the piston rod 64 . The outer protective shell 61 is sheathed outside the inner protective shell 62 , and the inner protective shell 62 can slide relative to the cylinder barrel 63 and the outer protective shell 61 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com