An on-site calibration device for a hydraulic displacement servo system

A servo system, on-site calibration technology, applied in the field of geometric measurement, can solve the problem of inability to calibrate hydraulic displacement servo system, and achieve the effect of eliminating disturbance influence, eliminating Abbe error and improving calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

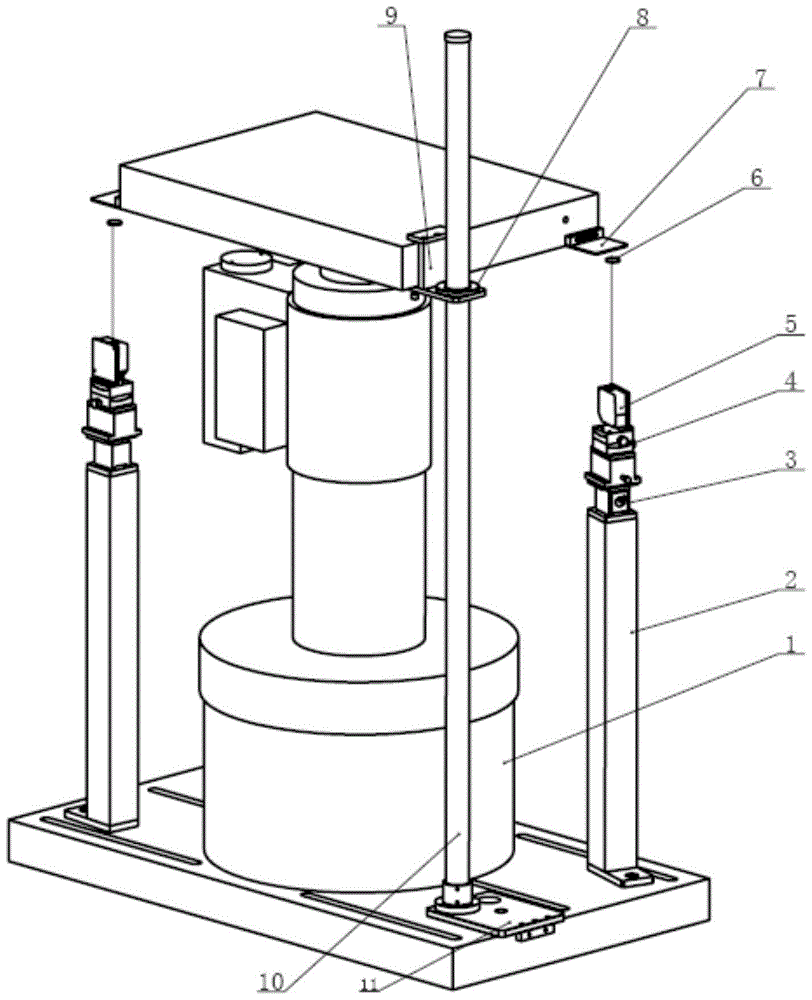

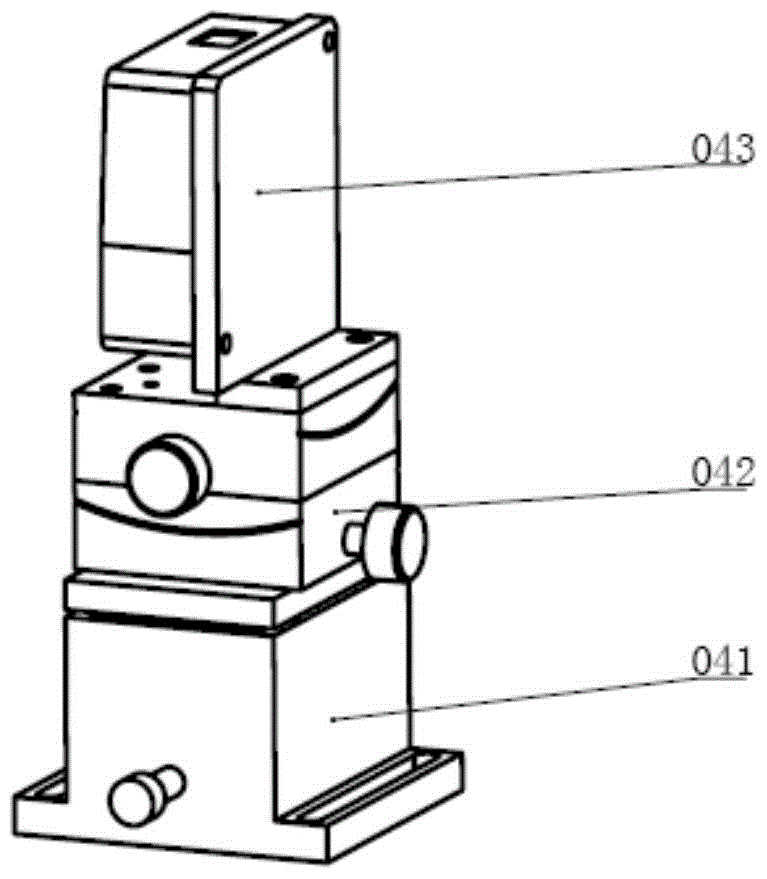

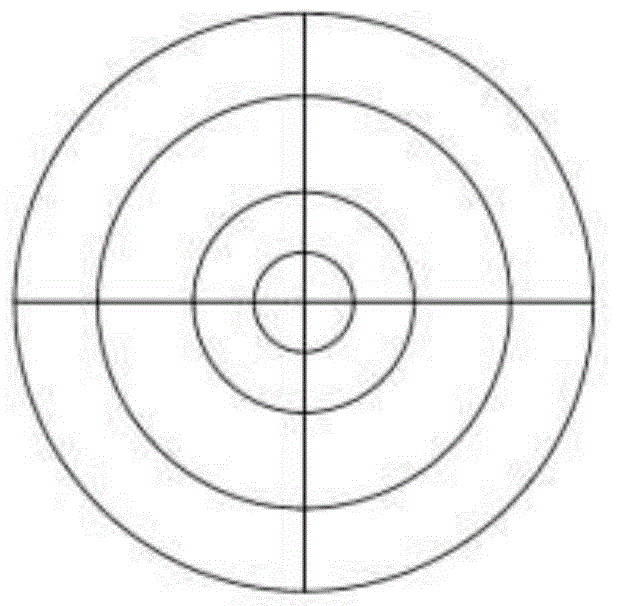

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an on-site calibration device for a hydraulic displacement servo system includes a two-way laser displacement sensor 5, a sensor pose adjustment mechanism 4, a column 2, a laser reflector 7, a magnetic target 6, and a guiding mechanism.

[0027] The two columns 2 are fixedly installed on the diagonally opposite positions of the hydraulic cylinder base, and the bottom of the column 2 is fixed by screws or the bottom of the column 2 is large and heavy enough so that the sensor pose adjustment mechanism can be placed stably, and it is placed directly on the hydraulic cylinder base. Yes, in order to make the device of the present invention highly versatile, the latter is adopted in this embodiment. The column can be made of aluminum profile, cast iron, steel and other materials, and the cross-sectional shape can be a stable shape such as a circle or a square. In addition, in order to facilitate installation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com