Industrial material drying device

A drying device and material technology, applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problems of inability to dry materials, unreasonable structural design, and increase enterprise costs, etc., to achieve good drying effect, Improve the stirring effect and the effect of drying quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

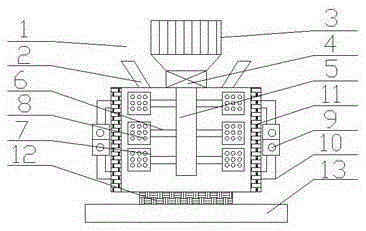

[0011] Such as figure 1 As shown, an industrial material drying device includes a body 1, the body 1 includes a feed port 2, a frequency conversion motor 3, a reducer 4 and a base 13, and a plurality of feed ports 2 are arranged on the top of the body 1; A variable frequency motor 3 is arranged above the body 1; the output part of the variable frequency motor 3 is connected to a reducer 4; the output part of the reducer 4 is connected to a stirring shaft 5; and the surface of the stirring shaft 5 is provided with a plurality of Connector 6; the top of the connector 6 is provided with a plurality of stirring pieces 7; the outer wall of the body 1 is provided with a fan 9; the bottom of the body 1 is provided with a base 13; a buffer is provided between the base 13 and the body 1 Layer 12.

[0012] The fan 9 communicates with the inside of the main body 1 through the air duct 10, and can timely pass air into the inside of the main body 1, so that the material inside the main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com