An Optical Alignment Measurement Method Based on Rigid-Flexible Transformation Platform

A measurement method and optical technology, which is applied in the field of optical alignment measurement based on a rigid-flexible conversion platform, can solve the problems of low alignment accuracy and reliability, and achieve the effect of fast observation speed and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] An optical centering measurement method based on a rigid-flexible conversion platform, the specific steps of which are:

[0035] The first step is to build the optical centering device

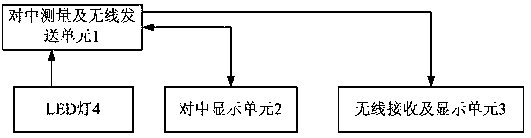

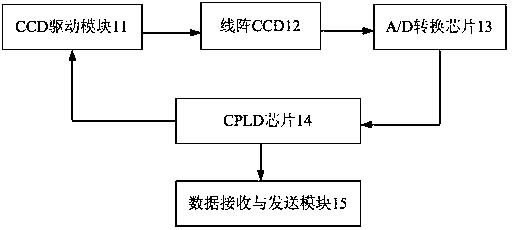

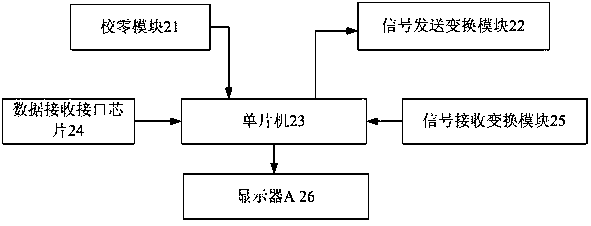

[0036] The optical centering device includes: a centering measurement and wireless sending unit 1 , a centering display unit 2 , an LED light 4 and a wireless receiving and displaying unit 3 . Among them, the centering measurement and wireless sending unit 1 includes: CCD driver module 11, linear array CCD12, A / D conversion chip 13, CPLD chip 14 and data receiving and sending module 15; centering display unit 2 includes: zero calibration module 21 , signal transmission conversion module 22, single-chip microcomputer 23, data receiving interface chip 24, signal reception conversion module 25 and display A26; wireless receiving and display unit 3 comprises: CPU31, power supply 34, display B32 and wireless data receiving module 33.

[0037] The output end of the alignment measurement and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com