Bragg grating biochemical sensor and method at interface between fiber core and cladding

A biochemical sensor and optical fiber core technology, applied in the field of Bragg grating biochemical sensors, can solve the problems of weak resonance intensity of reflected cladding mode and fiber core mode, low resonance reflection intensity of cladding mode, etc. The results are stable and reliable, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

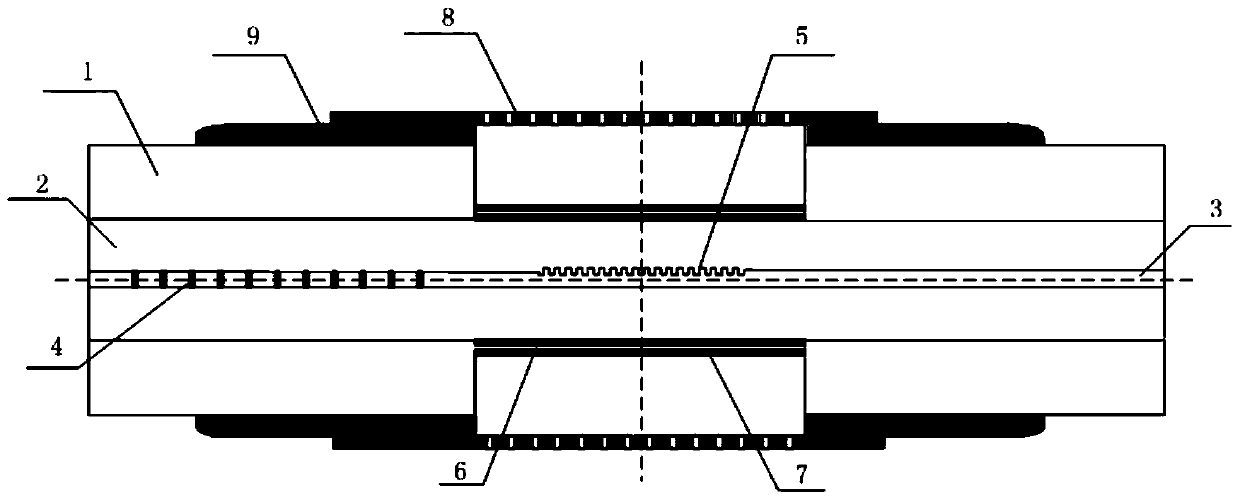

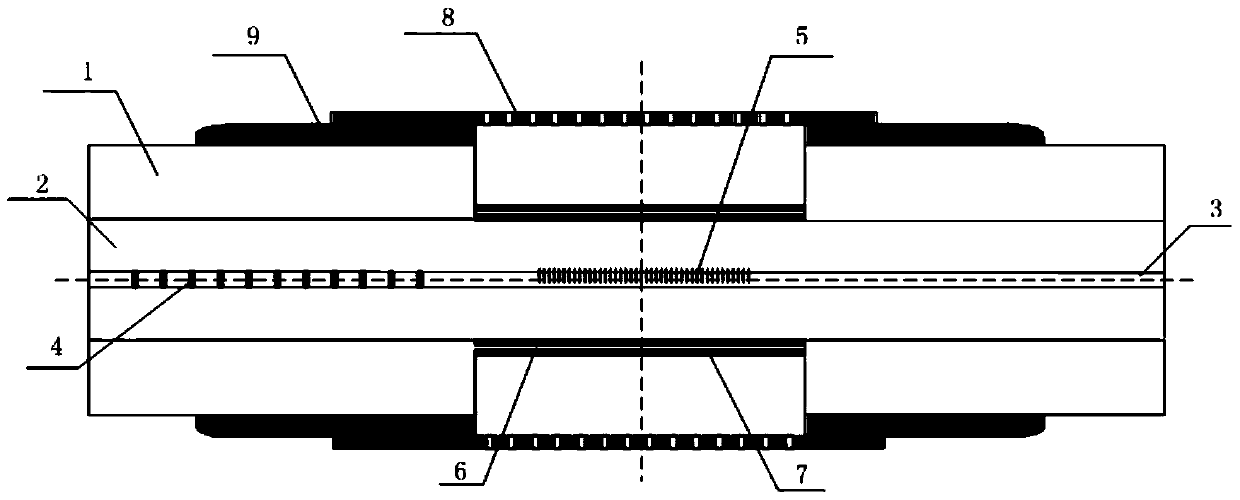

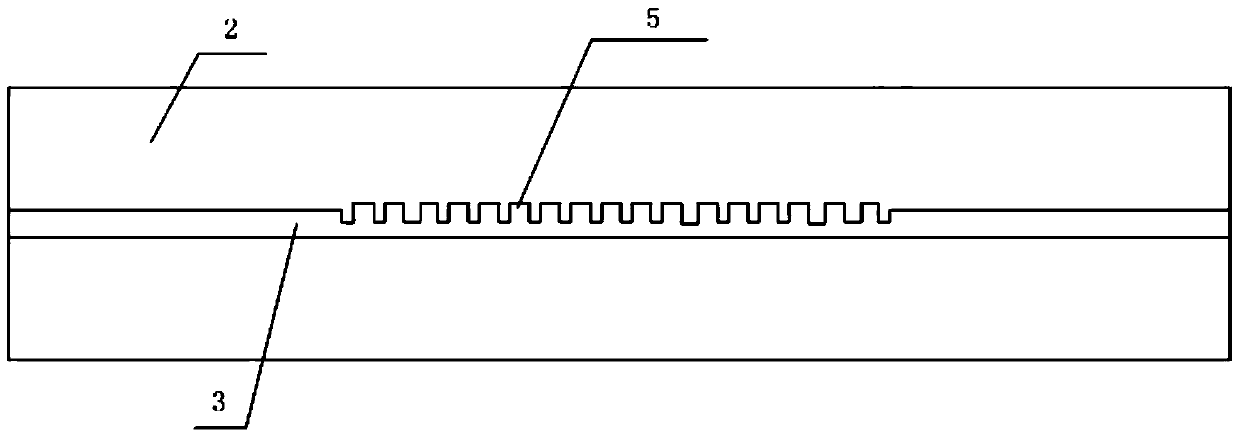

[0031] See Figure 1 to Figure 6 , The Bragg grating biochemical sensor at the interface of the fiber core and the cladding, including the fiber core 3 and the fiber cladding 2 that wraps the fiber core 3, characterized in that: a long-period fiber grating 4 is provided in the front section of the fiber core 3 The long-period fiber grating 4 is used as an optical resonant coupler of the fiber core 3 and the fiber cladding 2, and is used to couple the core mode to the same direction cladding mode or the cladding mode to the core mode; The middle section is located at the interface between the fiber core 3 and the fiber cladding 2 with a Bragg grating 5 at the interface between the fiber core and the cladding; the Bragg grating 5 at the interface between the fiber core and the cladding is composed of a number of linear grooves or It is composed of a number of dot-shaped grooves; the linear grooves or dot-shaped grooves present a periodic distribution along the axial direction of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| coupling | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com