Front shell component and metal front shell structure of electronic equipment

A technology of electronic equipment and front shell, which is applied in the field of electronic equipment, can solve the problems that are contrary to the development needs of light and thin electronic equipment, and the thickness of electronic equipment increases, and achieve the effect of meeting the development needs of light and thin and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

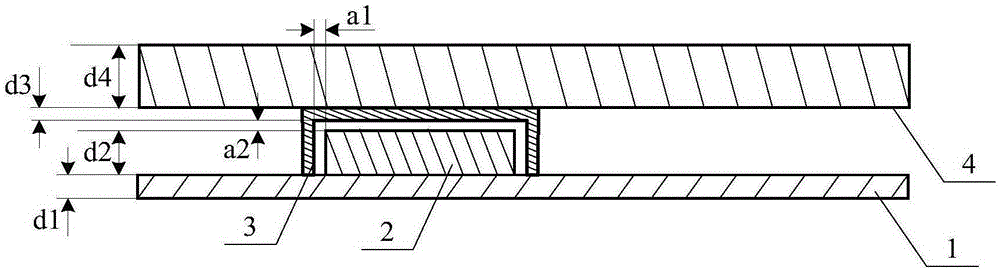

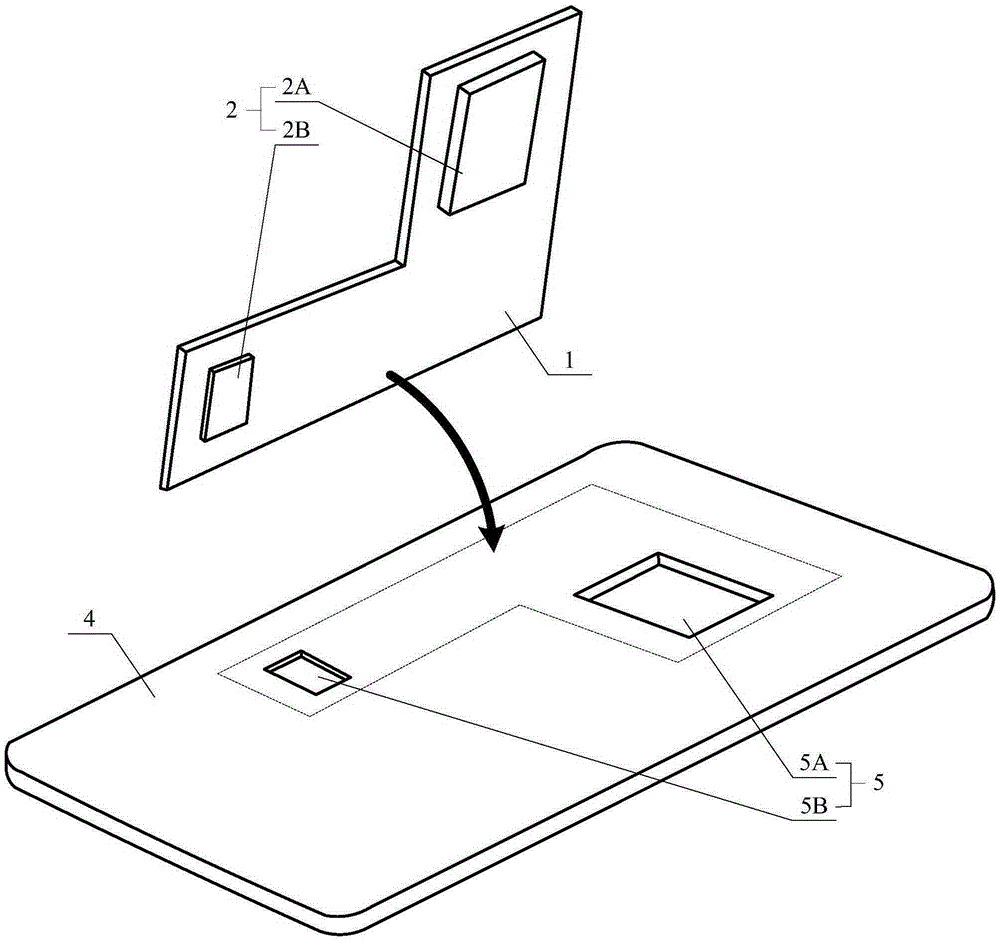

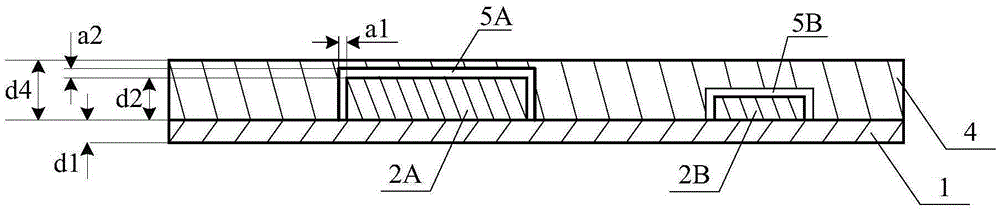

[0038] Figure 2A It is a three-dimensional schematic diagram of a metal front shell structure and a printed circuit board of an electronic device according to one of the exemplary embodiments, such as Figure 2A As shown, the electronic device is provided with a printed circuit board 1 adjacent to the metal front shell structure 4, and the side of the printed circuit board 1 close to the metal front shell structure 4 is provided with a number of devices to be shielded 2 (such as devices to be shielded) 2A and the device to be shielded 2B); where:

[0039] The metal front shell structure 4 is provided with a number of grooves 5 corresponding to the device to be shielded 2 (for example, groove 5A corresponding to the device to be shielded 2A, and groove 5B corresponding to the device to be shielded 2B), and each The opening position and size specifications of a groove 5 are matched to the corresponding device to be shielded 2, so that when the metal front shell structure 4 and the ...

Embodiment 2

[0045] Figure 3A Is a cross-sectional view of an electronic device according to the second exemplary embodiment, such as Figure 3A As shown, this embodiment provides a front housing assembly of an electronic device, and the front housing assembly includes:

[0046] The metal front shell structure 4 is provided with a number of through holes 5'(such as through holes 5'A and through holes 5'A and 2B) corresponding to the device to be shielded 2 (such as the device to be shielded 2A and the device to be shielded 2B) one-to-one Through hole 5'B etc.);

[0047] The metal sheet 6 closes the end of the through holes 5'far away from the printed circuit board 1 in the electronic device, so that the metal sheet 6 and the through holes 5'form corresponding groove structures (in the figure Not labeled); wherein, the metal sheet 6 is also electrically connected to the metal front shell structure 4;

[0048] Wherein, the opening position and size specifications of each through hole 5'are matche...

Embodiment 3

[0058] Figure 4 Is a cross-sectional view of an electronic device according to the third exemplary embodiment, such as Figure 4 As shown, the current case assembly includes a number of metal sheets 6 (such as metal sheets 6A and metal sheets 6B, etc.) corresponding to a number of through holes 5'(such as through holes 5'A and through holes 5'B, etc.), and each When a metal sheet 6 respectively closes the end of the corresponding through hole 5'far away from the printed circuit board 1 to form a corresponding groove structure, each metal sheet 6 can be respectively embedded in the corresponding through hole 5', and the metal The outer surface of the sheet 6 and the side of the metal front shell structure 4 away from the printed circuit board 1 are on the same plane.

[0059] Therefore, in this embodiment, by embedding several metal sheets 6 into the through holes 5', Figure 2B The structure shown in the first embodiment is similar; however, compared with the structure shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com