fuel high pressure pump

A high-pressure pump and fuel technology, applied in the direction of fuel injection pump, fuel injection device, liquid fuel engine, etc., to achieve the effect of simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

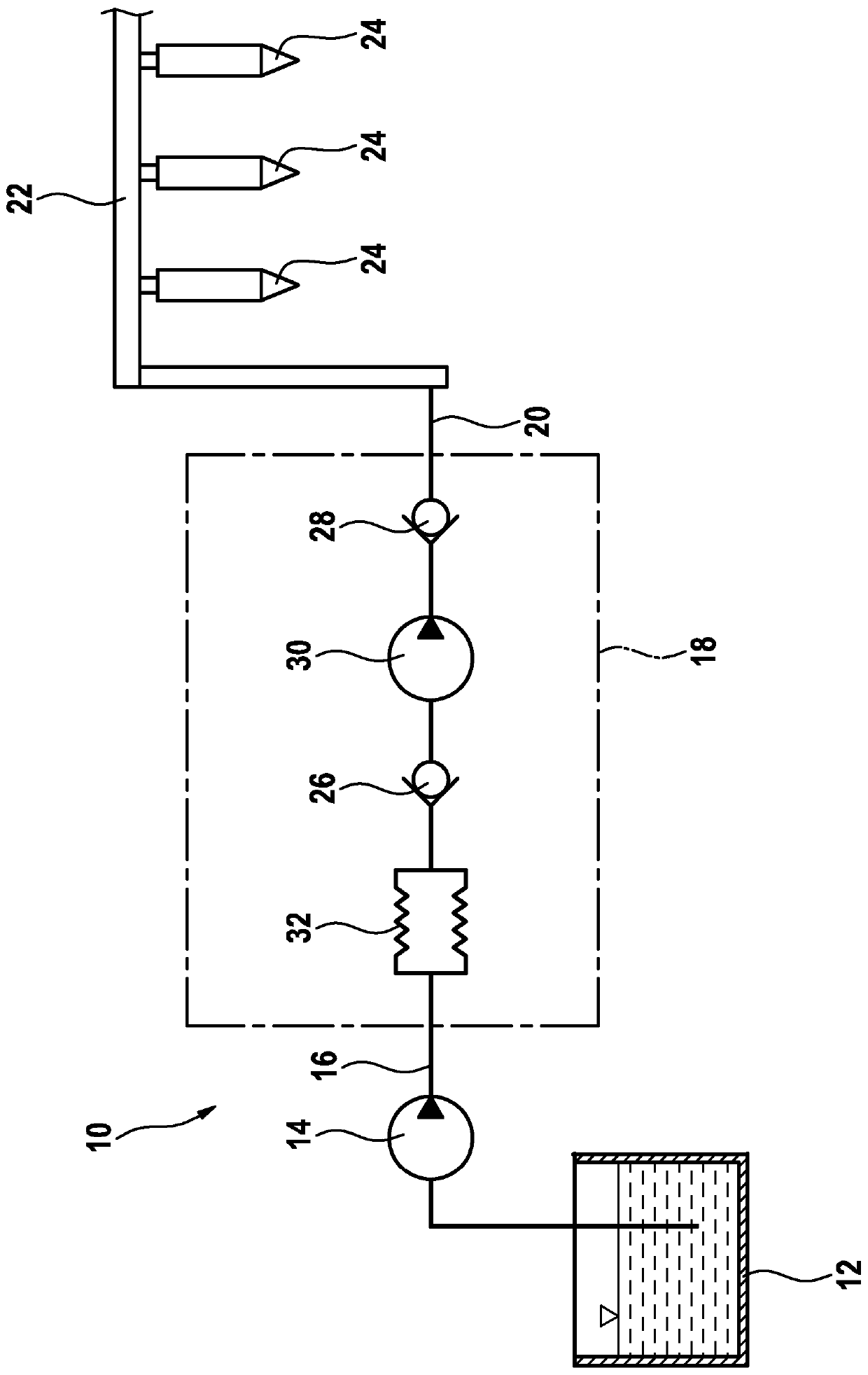

[0015] exist figure 1 , the fuel system of the internal combustion engine is generally designated with reference numeral 10 . The fuel system includes a fuel container 12 for receiving fuel. Connected to the fuel container 12 is an electric backing pump 14 . A low-pressure line 16 is again attached to the electric backing pump 14 . This low-pressure line leads to a high-pressure fuel pump 18 , which is generally indicated by a dash-dotted line and is designed in the exemplary embodiment in the form of a piston pump. A high-pressure line 20 leads from the high-pressure fuel pump to a fuel rail 22 . A plurality of injectors 24 are attached to the fuel rail 22 . A fuel delivery flow in fuel system 10 is directed from fuel container 12 to injector 24 .

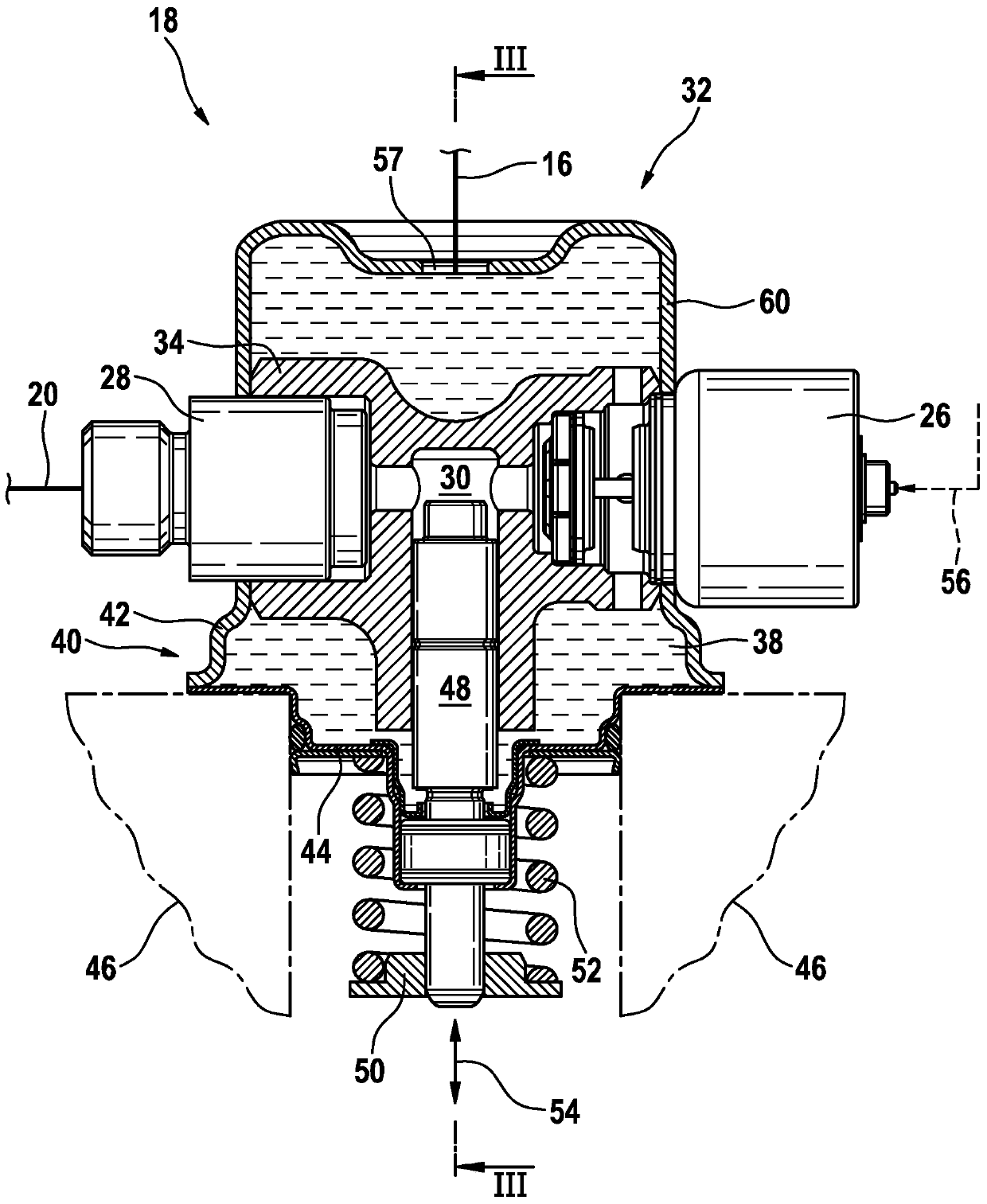

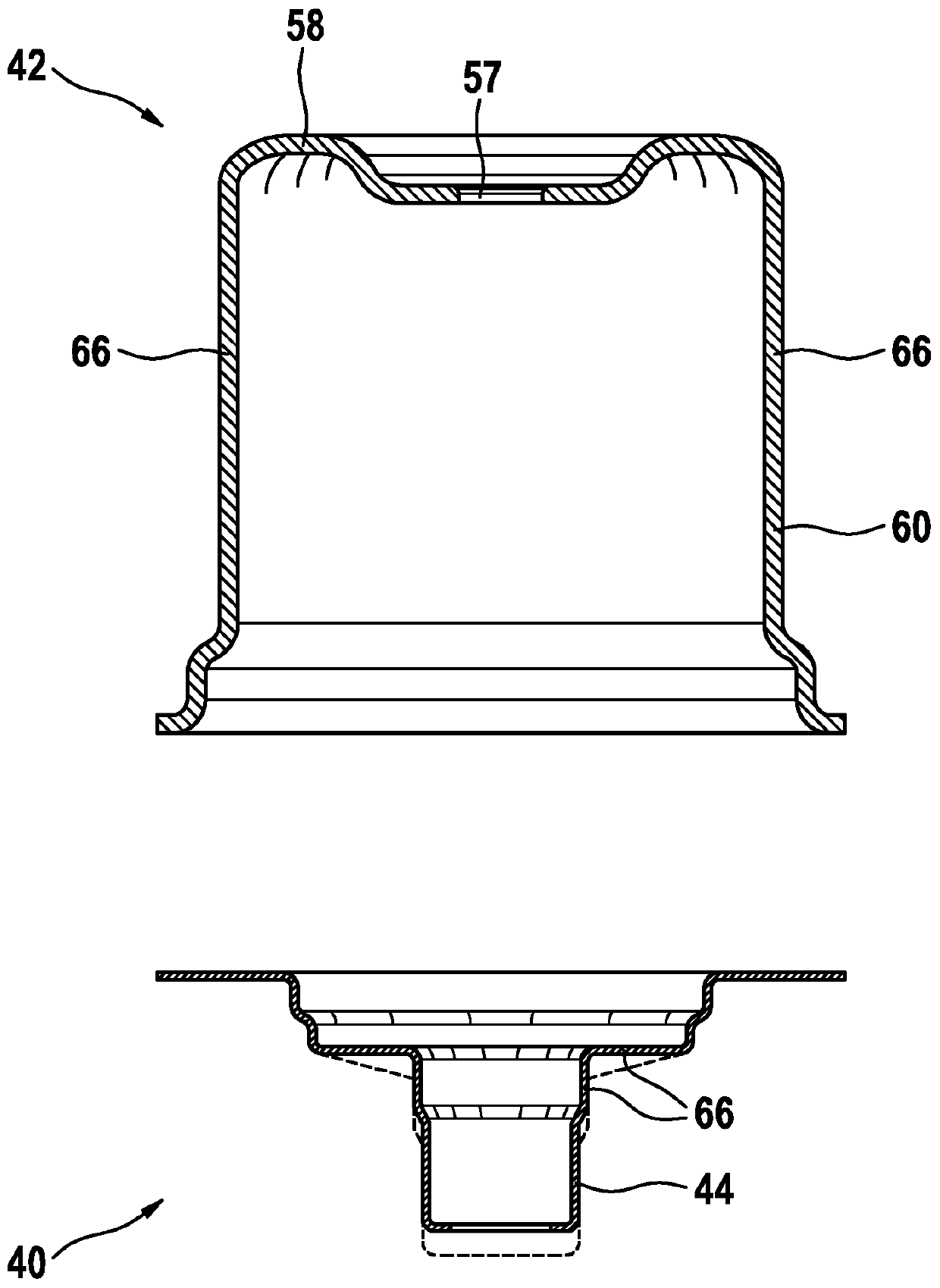

[0016] The high-pressure fuel pump 18 comprises an inlet valve 26 embodied as a check valve and an outlet valve 28 embodied as a check valve, as well as a displacement chamber 30, which in the figure 1 are shown by known pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com