Fan shroud assembly

A technology for fans and shields, applied in the field of fan shield assemblies, can solve the problems of increased noise, increased pressure variation, and non-symmetrical shape of the fan shield assembly 20, and achieves the effects of reducing noise and preventing sticking or freezing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] best practice

[0045] Hereinafter, the fan shroud assembly according to the present invention as described above will be described in detail with reference to the accompanying drawings.

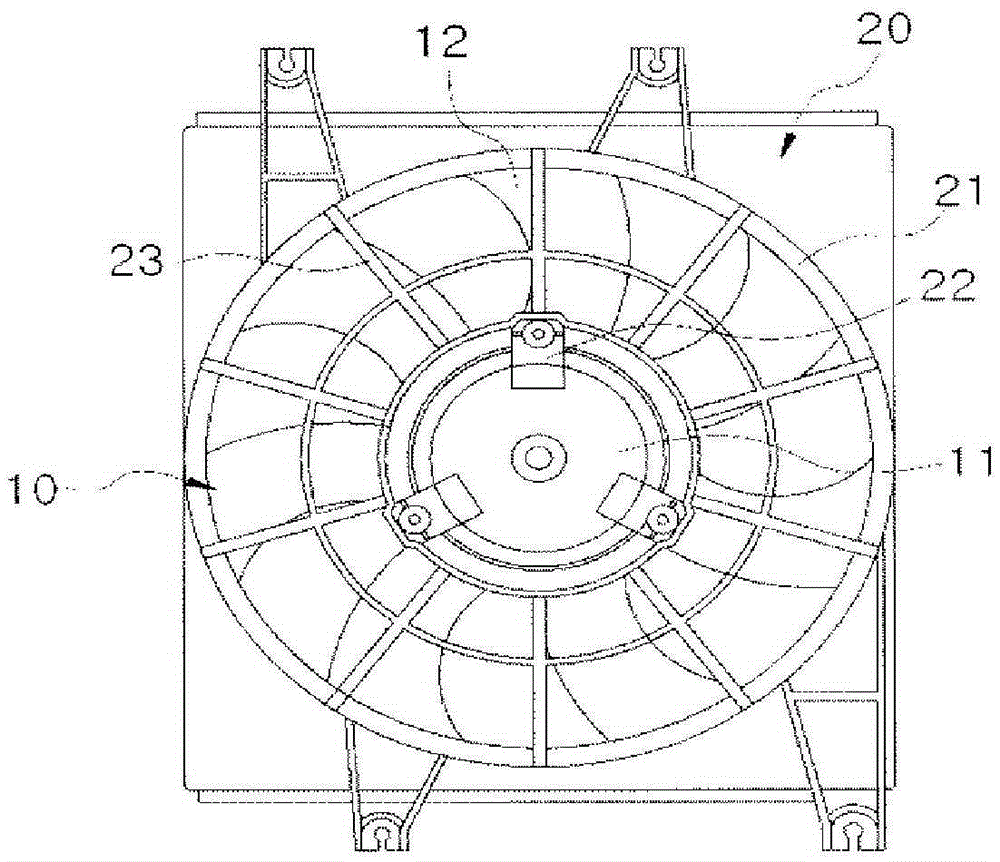

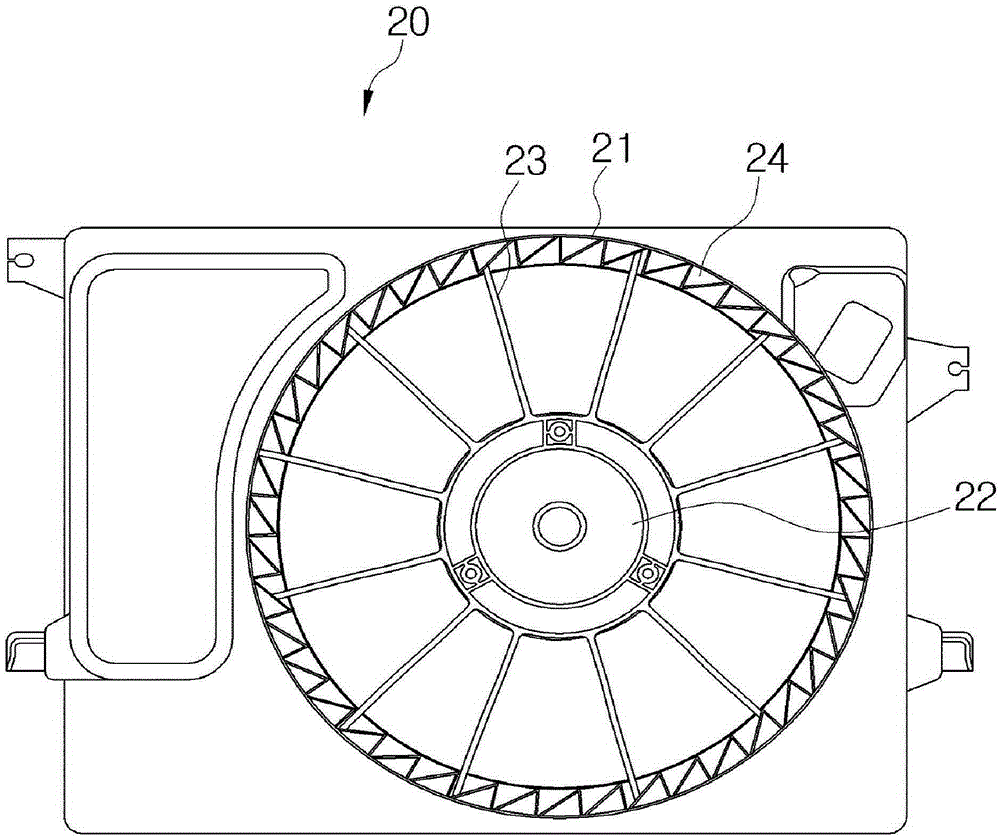

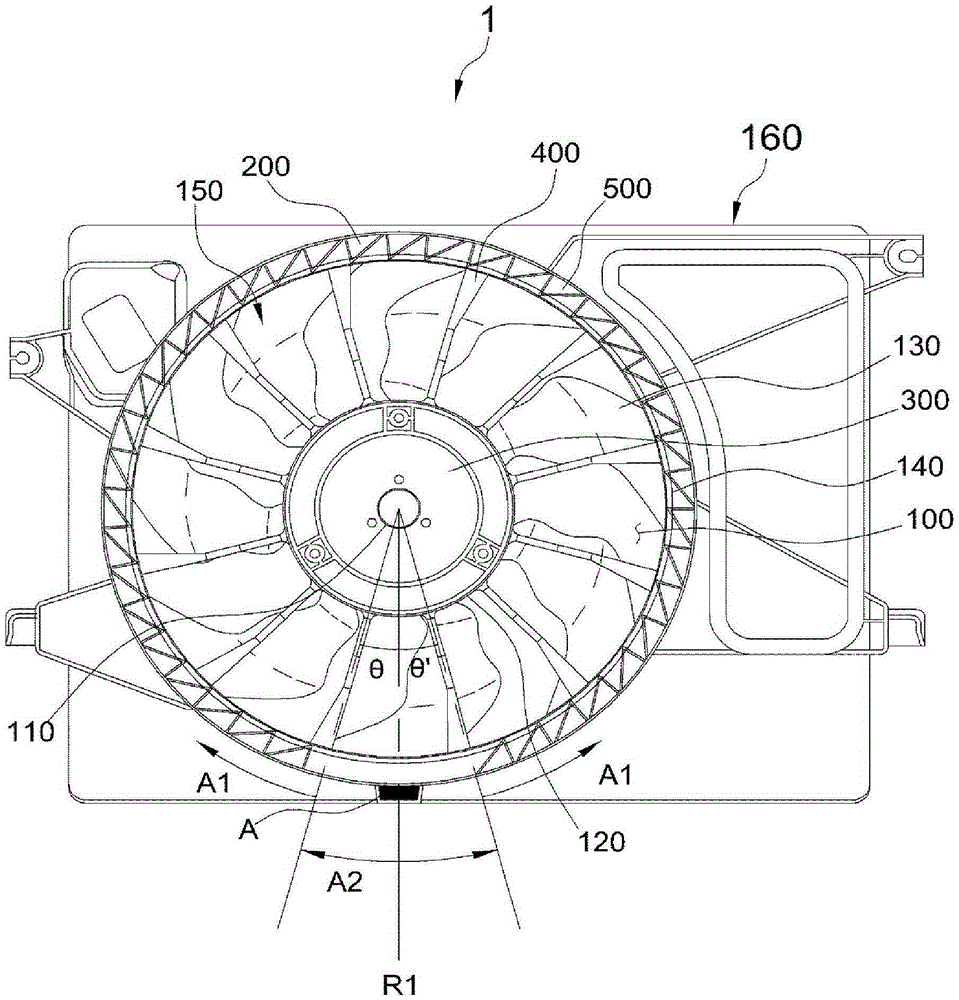

[0046] like image 3 As shown, the fan shroud assembly 1 according to the present invention is generally composed of a fan 150 and a shroud 160 .

[0047] First, the fan 150 is a rotary fan that transmits blown air to the heat exchanger of the vehicle while being rotated by the motor 110, and includes: a hub 120, blades 130 and a fan ring 140, and the shroud 160 includes: a cone Shaped mouth 200 , motor assembly part 300 and fixing piece 400 .

[0048] First, in order to move air by means of the fan 150, the tapered opening 200 forms an air blowing portion 100, which is a space in which a predetermined central area of a plenum portion is hollow.

[0049] The electrode assembly part 300 is a part for assembling the motor for driving the fan 150 , and is located in the central area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com