Needle Assembly

A technology of puncture needles and components, applied in the direction of puncture needles, trocars, etc., can solve the problems of inaccurate puncture points, retreat into the right atrium cavity, serious complications, etc., and achieve the effect of reducing the difficulty of operation techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

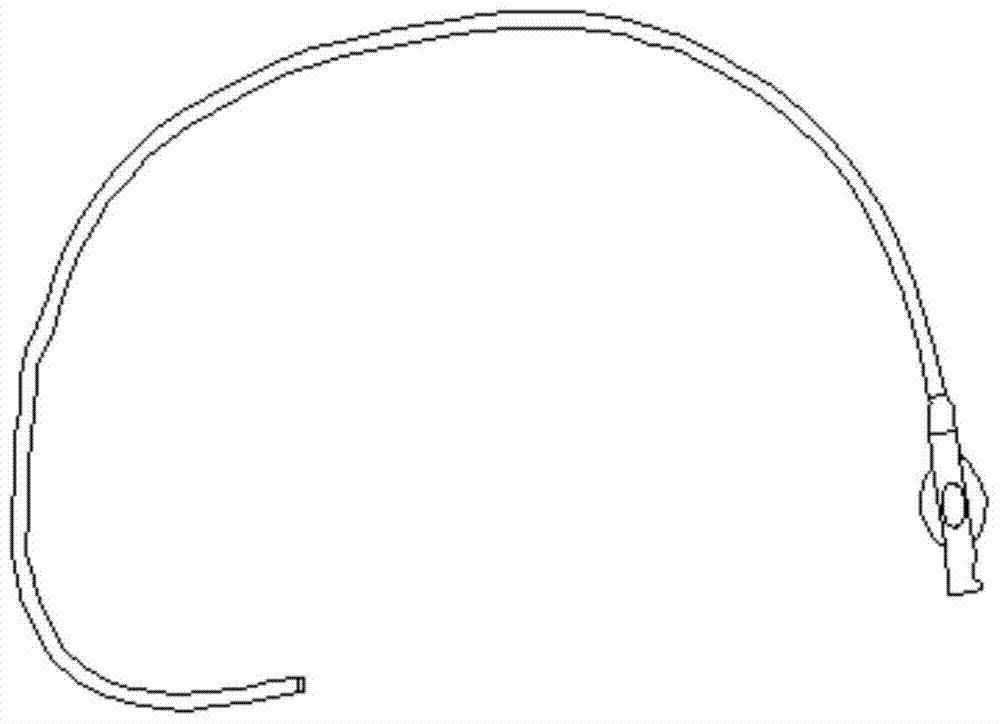

[0033] Such as figure 1 , figure 2 and image 3 As shown, the puncture needle assembly of the present invention includes a puncture needle, a guide wire, a sheath with a dilator, and a three-dimensional stereotaxic positioning device, and the guide wire is arranged inside the puncture needle to form an integrated guide wire A solid-core puncture needle in the shape of a guide wire is respectively connected with the sheath tube with a dilator and the three-dimensional stereotaxic orientation device.

[0034] In the puncture operations such as interventricular septal puncture and atrial septal puncture through venous puncture, when the puncture needle assembly of the present invention is used, the three-dimensional stereotaxic positioning device is used to objectively select the interventricular septal puncture target, and the guide wire The solid core puncture needle is used to pass through the interventricular septum according to the puncture target point and establish a gu...

Embodiment 2

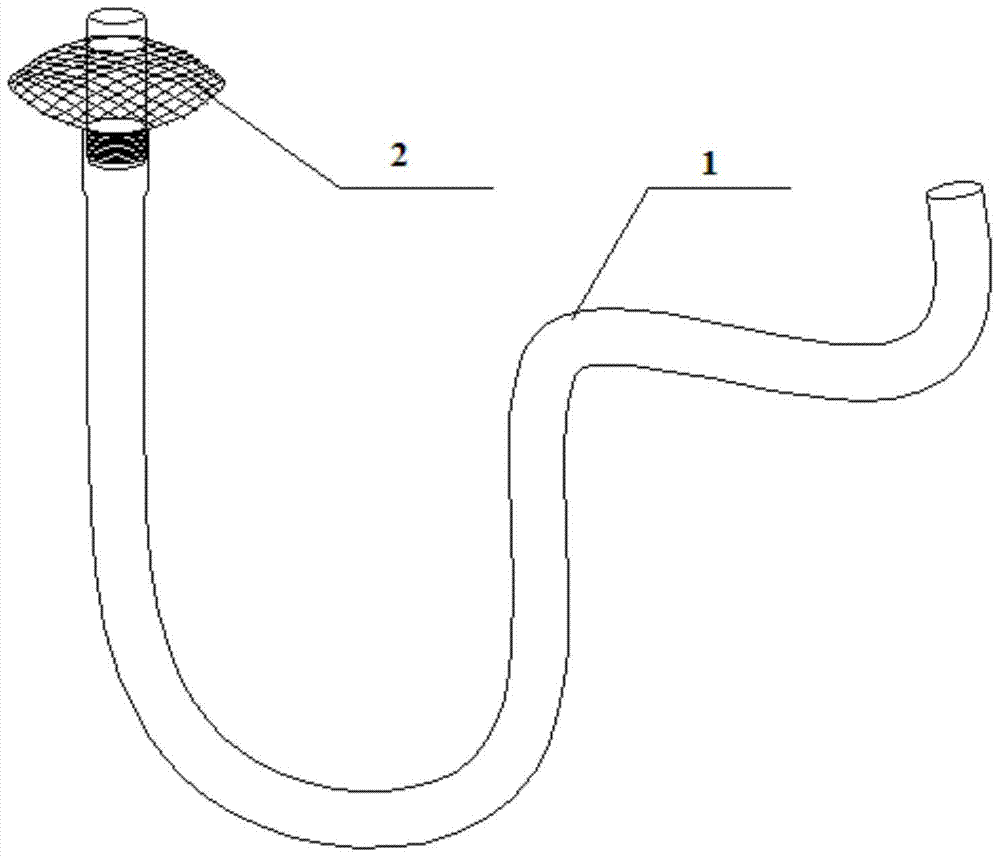

[0036] Such as Figure 1 to Figure 5 As shown, the puncture needle assembly of the present invention has the same basic structure and application as in Embodiment 1. Specifically, it also has the following settings: the three-dimensional stereotaxic orientation device is composed of a connected delivery cable 1 and a three-dimensional stereotaxic positioner 2 It consists of two parts; a central cavity is provided in the delivery steel cable 1, and the guide wire-shaped solid core puncture needle is set in the central cavity of the delivery cable 1 and is perpendicular to the plane where the three-dimensional stereotaxic positioner 2 is located.

[0037] In the above embodiments, in order to ensure the precise positioning of the puncture target and the stability of long-term use, such as Figure 5 The head end of the three-dimensional stereotaxic localizer 2 shown is a metal mesh cage type, which is woven by shape memory alloy wire; as Figure 4 The conveying steel cable 1 sho...

Embodiment 3

[0043] Such as Figure 1 to Figure 5 As shown, the basic structure and application of the puncture needle assembly of the present invention are the same as those in Embodiment 1 or Embodiment 2. Specifically, it also has the following settings:

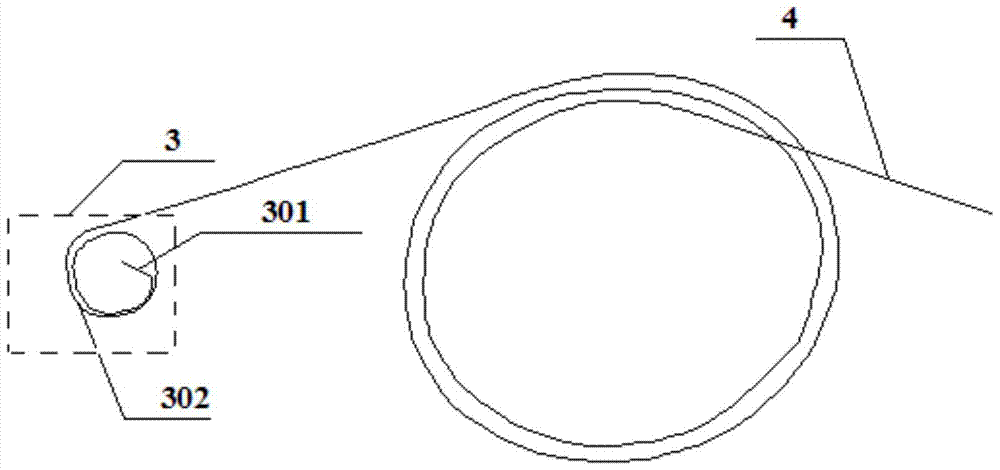

[0044] The guide wire-shaped solid core puncture needle comprises a connected head 3 and a body 4, the body 4 is a linear structure, and the head 3 is a needle-shaped structure with a tapered tip; the head 3 includes a corresponding Connected straight tough section 301 and curved section 302, the curved section 302 is a soft segment structure coiled in a circumferential shape, the straight tough section 301 is a needle tip section part with a needle point, the circumferential plane of the straight tough section 301 and the curved section 302 perpendicular to each other.

[0045]In the above-mentioned embodiments, in order to ensure the puncture effect and fully protect the surrounding organs and tissues, the body 4 is preferably a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com