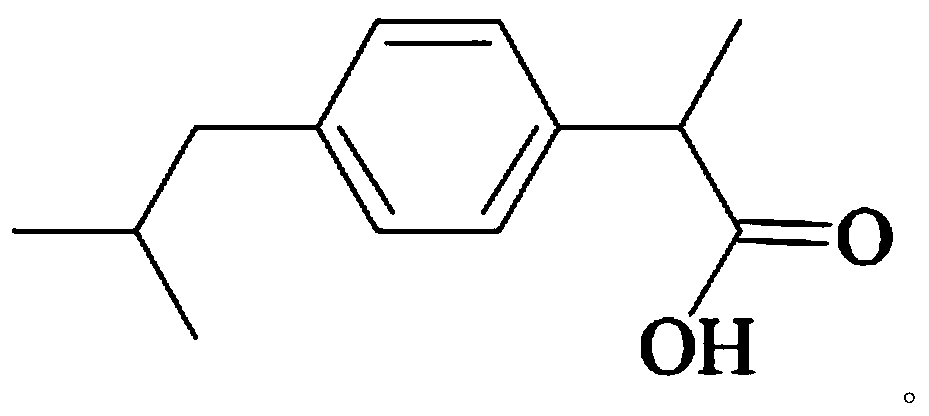

A kind of ibuprofen sustained-release pellets and preparation method thereof

A technology of slow-release pellets and slow-release materials, which is applied in the field of medicine, can solve the problems of poor slow-release effect and difficult control of drug release rate, and achieve good slow-release effect, stable sustained-release effect, and controlled drug release rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

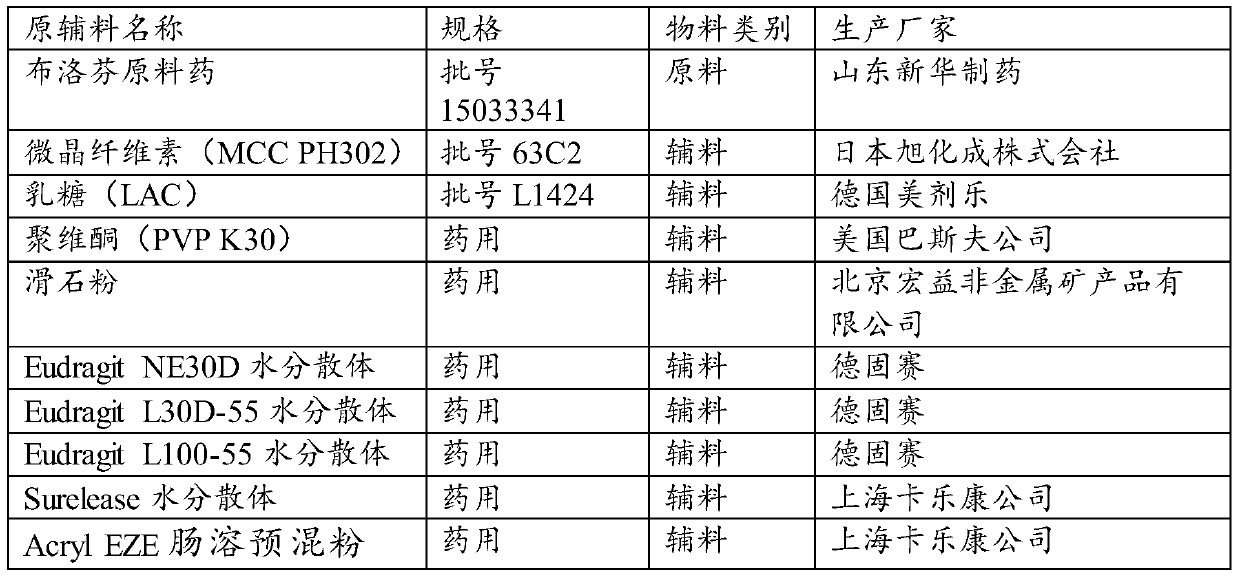

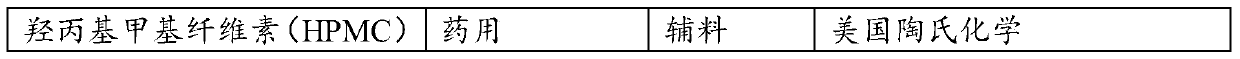

[0055] The present invention also provides a preparation method of the ibuprofen sustained-release pellets described in the above technical scheme, comprising the following steps:

[0056] a) granulating after mixing ibuprofen, disintegrating agent, filler and binding agent to obtain drug-containing pills; the disintegrating agent is microcrystalline cellulose;

[0057] b) coating the drug-containing pill with a sustained-release material to obtain ibuprofen sustained-release pellets;

[0058] The sustained-release material is polymethacrylate or ethyl cellulose.

[0059] In the present invention, the ibuprofen, the disintegrating agent, the filler and the binding agent are mixed and granulated to obtain the drug-containing pill. In the present invention, the ibuprofen is the main ingredient; the source of the ibuprofen is not particularly limited in the present invention, and commercially available products well known to those skilled in the art can be used. In the present ...

Embodiment 1

[0096] (1) Stir and mix 200g ibuprofen crude drug, 90g MCC PH302, and 10g LAC in a HLSH2-6 type wet mixing granulator, the chassis rotation speed of stirring is 600rpm, and the side disk rotation speed is 1200rpm to obtain the mixed powder; Then keep the stirring condition unchanged, add 100g of PVP K30 aqueous solution with a mass fraction of 10% to the above mixed powder to obtain a soft material.

[0097] (2) Move the above-mentioned soft material to the E50 extruder, and extrude it for 2 minutes under the condition of extrusion speed of 30rpm to obtain a strip; then the above-mentioned strip is spheronized in the s-250 spheronizer After 3 minutes, the rotating speed of spheronizing is 1200rpm to obtain vegetarian pills; then the above-mentioned vegetarian pills are dried in a CS101-2ABN type hot air circulation box for 12 hours at a drying temperature of 40°C; finally passed through a 20-30 mesh sieve to obtain drug-containing vegetarian pills.

[0098] (3) Get 16.7g Eudra...

Embodiment 2

[0105] (1) Stir and mix 200g ibuprofen crude drug, 80g MCC PH302, and 20g LAC in a HLSH2-6 type wet mixing granulator, the chassis rotation speed of stirring is 600rpm, and the side disk rotation speed is 1200rpm to obtain the mixed powder; Then keep the stirring condition unchanged, add 100g of PVP K30 aqueous solution with a mass fraction of 10% to the above mixed powder to obtain a soft material.

[0106] (2) Move the above-mentioned soft material to the E50 extruder, and extrude it for 2 minutes under the condition of extrusion speed of 30rpm to obtain a strip; then the above-mentioned strip is spheronized in the s-250 spheronizer After 3 minutes, the rotating speed of spheronizing is 1200rpm to obtain vegetarian pills; then the above-mentioned vegetarian pills are dried in a CS101-2ABN type hot air circulation box for 12 hours at a drying temperature of 40°C; finally passed through a 20-30 mesh sieve to obtain drug-containing vegetarian pills.

[0107] (3) get 32g Surelea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com