Automatic element inserting machine control system based on industrial robot

An automatic plug-in machine and industrial robot technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problem of low assembly progress of plug-in machines, and achieve the effects of precise plug-in, strong anti-interference, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be clearly and completely described below.

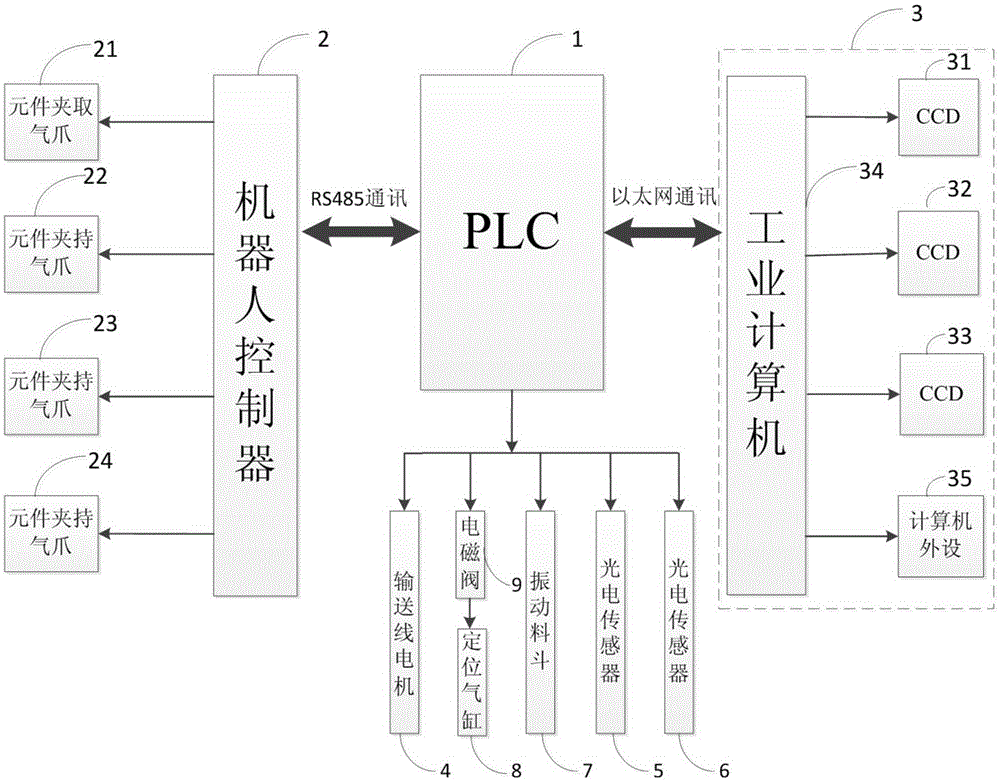

[0031] figure 1 It is a structural block diagram of an industrial robot-based automatic plug-in machine control system provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the control system includes a conveyor line motor 4, a photoelectric sensor 5, a photoelectric sensor 6, a material picking device, a vibrating hopper 7, a clamping and positioning device, a robot controller 2, a PLC controller 1 and a vision subsystem 3.

[0032] Conveyor line motor 4 , photoelectric sensor 5 , photoelectric sensor 6 , material picking device, vibrating hopper 7 , clamping and positioning device, robot controller 2 and vision subsystem 3 are all connected to PLC controller 1 . Specifically, the PLC controller 1 communicates with the robot controller 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com