A non-orthogonal structure casing processing method and fixture

A processing method and non-orthogonal technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of installation positioning, clamping and alignment difficulties, installation edge and casing cylinder are not perpendicular, difficult Guarantee the processing quality of the casing and other issues, and achieve the effect of solving the installation and positioning difficulties of milling and turning composite processing, good application prospects, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

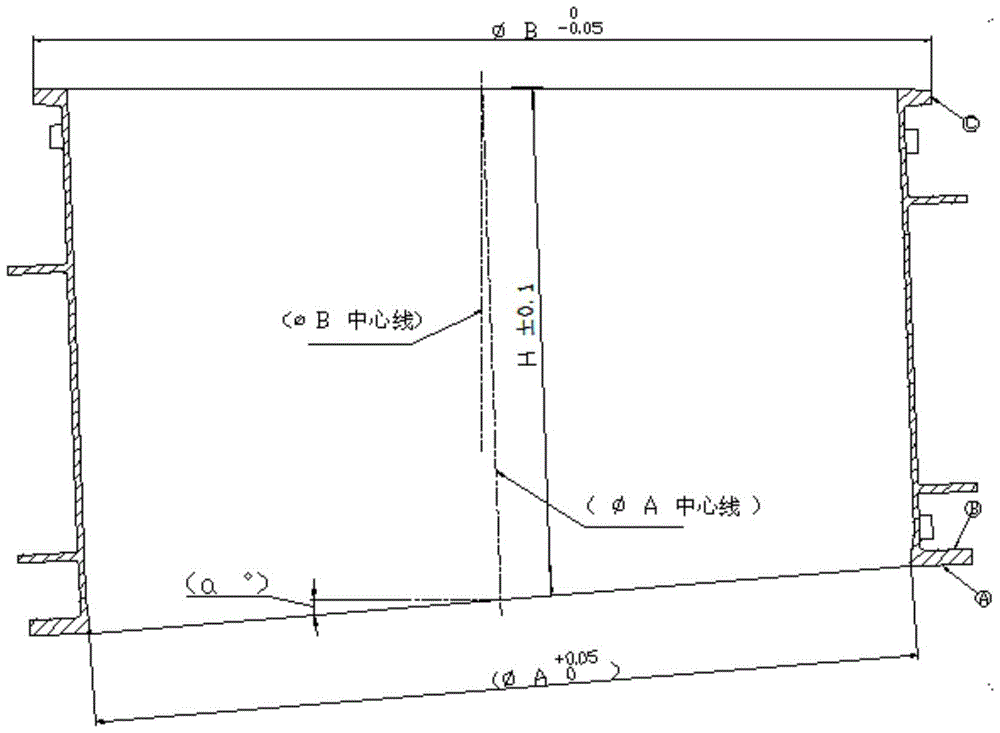

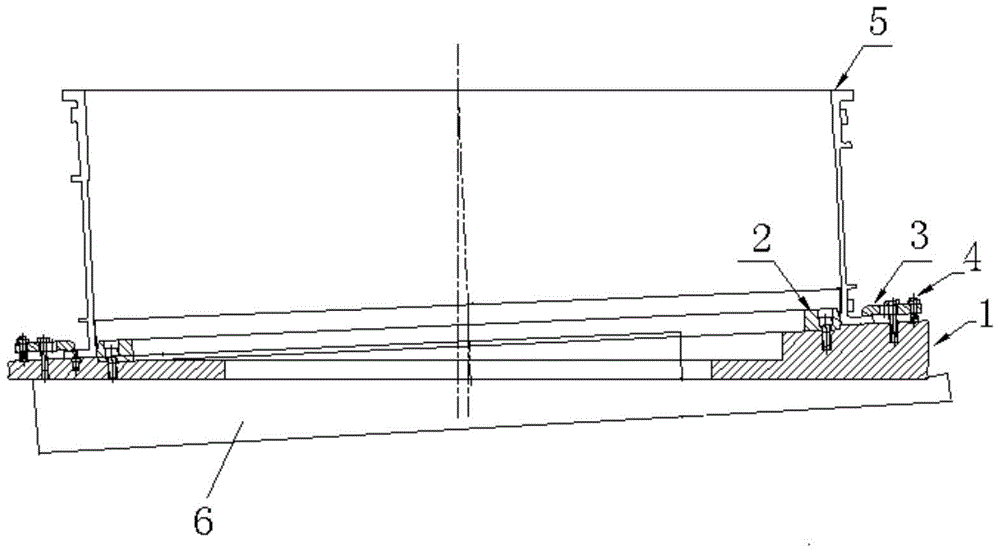

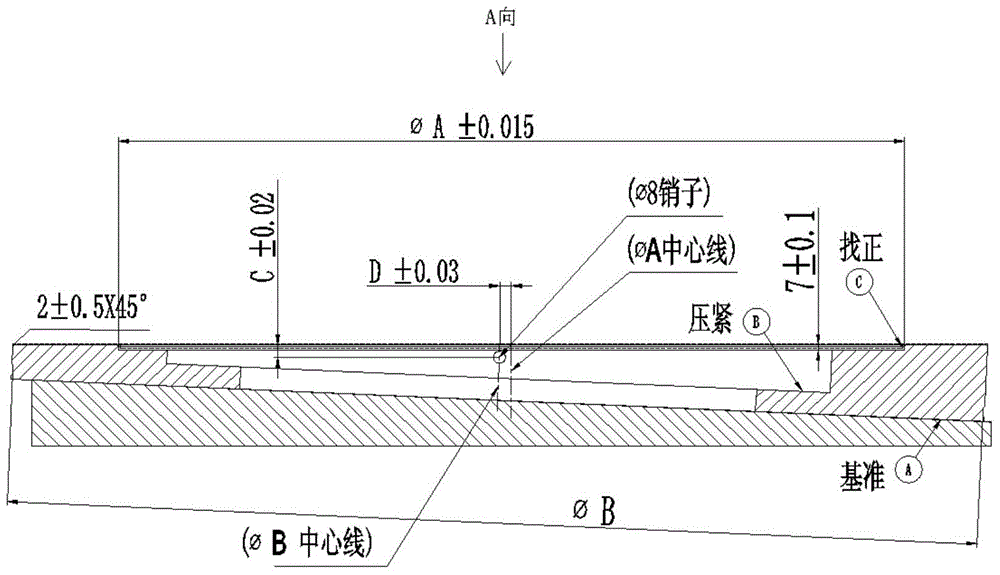

[0022] The structure of the present invention is as figure 2 As shown, it includes the bottom angle plate 6, the base 1 is set on the angle plate 6, and the positioning ring 2 is set on the base 1, and the positioning ring 2 is fixed on the base 1 by using a pressure plate and bolts 4; Pressing plate 2 3, pressing plate 2 is used to fix the outer bottom edge of the casing on the base; the positioning ring 2 matches the shape of the bottom of the casing 5, and the inclination angle between the upper surface of the base 1 and the horizontal plane is perpendicular to the center line of the casing The deflection angle between the directions is consistent; the base 1 can rotate relative to the angle plate 6, and a positioning pin is arranged between the base 1 and the angle plate 6; the positioning pin corresponds to the pin hole pre-set on the angle plate, and the pin hole The position of the machine is calculated and set according to the shape of the part to ensure the technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com