Impregnation method and impregnation device of reinforced material

A technology of reinforcing material and wetting device, applied in the coating and other directions, can solve the problems of affecting the appearance and functional properties of the sheet, increasing the viscosity of the resin glue, affecting the appearance of the bonding sheet, etc., to improve the appearance and increase the wetting ability. , the effect of bubble overflow smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

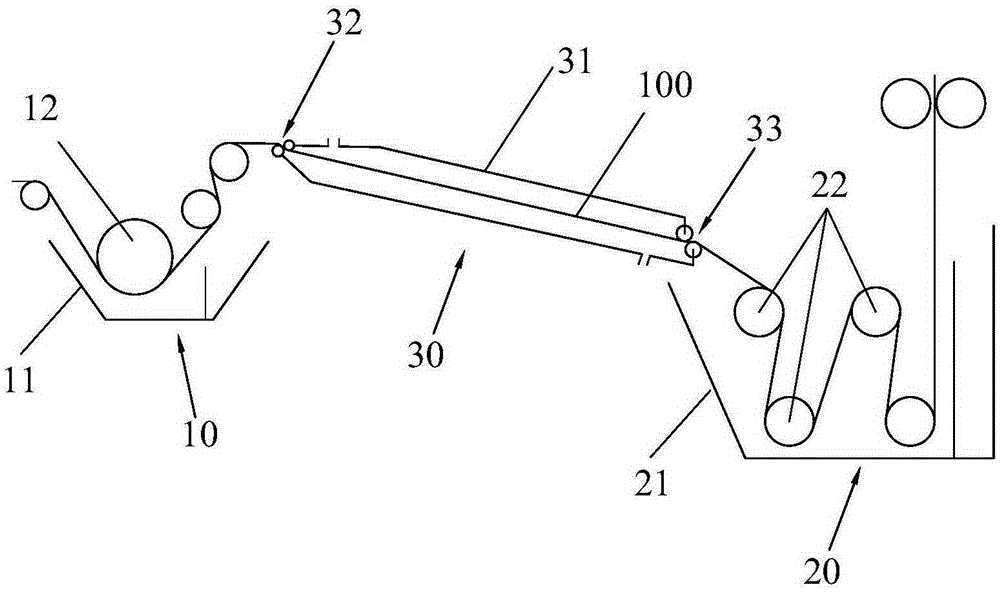

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

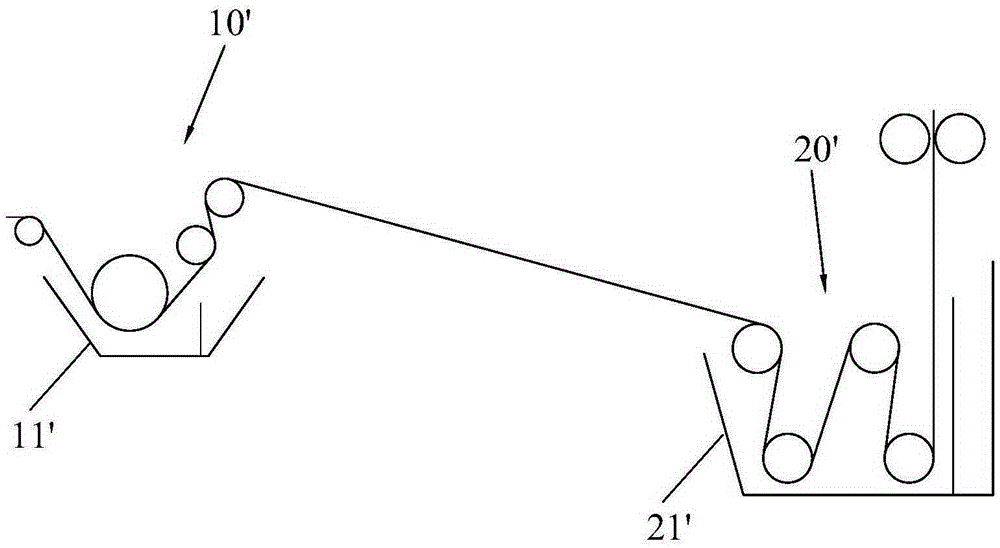

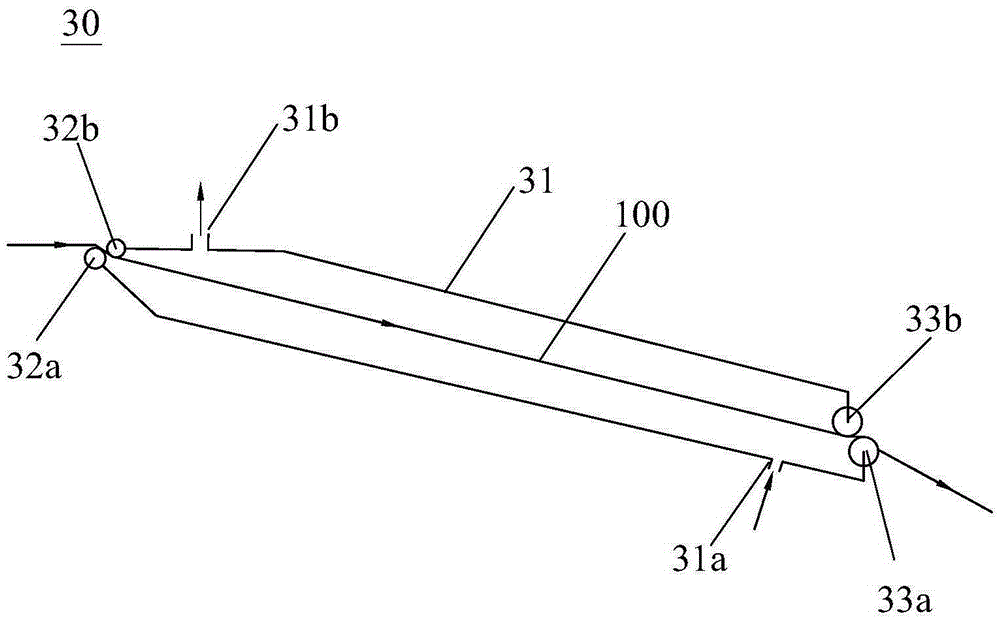

[0031] like figure 2 As shown, a wetting device for reinforcing material 100 is used for wetting with resin glue with filler, including a prepreg 10 for prepreg, a main impregnation 20 for main impregnation and a A re-dipping part 30 between the pre-dipping part 10 and the main dipping part 20; wherein, the re-dipping part 30 includes a closed re-dipping tank 31, and the entrance of the re-dipping tank 31 is close to the pre-dipping part 10, so as to The reinforcing material 100 coming out of the prepreg 10 enters the re-dipping tank 31 in a short time, and the outlet of the re-dipping tank 31 is close to the main dipping part 20, so that the reinforcing material 100 coming out of the re-dipping tank 31 takes a short time. Into the main immersion section 20; wherein, the re-immersion section 30 also includes a first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com