Hand-clamping prevention device of bottle blowing machine

The technology of an anti-pinch device and a bottle blowing machine is applied in the field of safety protection devices, which can solve the problems of easily hurting workers and the like, and achieve the effects of simple structure, reasonable design and good anti-pinch effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

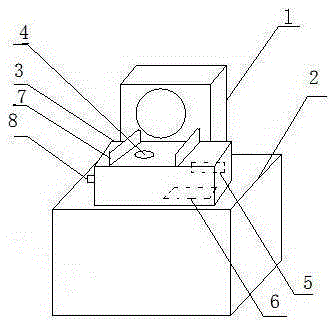

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a control cabinet 3 arranged on the upper part of the blow molding machine controller 2 on the front side of the blow molding machine 1, the blow molding machine controller 2 controls the operation and stop of the blow molding machine 1, and the upper surface of the control cabinet 3 is provided with an infrared sensor 4. The infrared sensor 4 is connected to the anti-pinch device controller 5 located inside the control cabinet 3; the inside of the control cabinet 3 is provided with a time relay 6; the anti-pinch device controller 5 is connected to the blowing bottle through the feedback control of the time relay 6 machine controller 2; the two sides of the infrared sensor 4 on the upper surface of the control cabinet 3 are provided with upright reflective baffles 7; the side surface of the control cabinet 3 has a setting button 8 for adjusting the setting time relay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com