Controllable 3D printer

A 3D printer, controllable technology, applied in the direction of additive processing, can solve the problems of time-consuming, laborious, manual completion, etc., to achieve the effect of improving the recycling effect, facilitating the operation, and reducing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

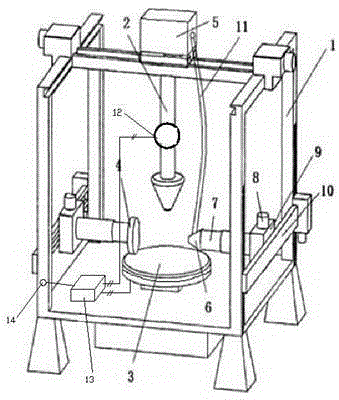

[0013] Such as figure 1 As shown, a controllable 3D printer includes a frame 1, a printing device 2 arranged on the top of the frame 1, and a workbench 3 arranged at the bottom of the frame 1, and a frame 1 is also provided on one side of the frame 1. There is a grinding device 4, a raw material tank 5 is arranged on the top of the printing device 2, and a suction nozzle 6 is arranged on the opposite side where the grinding device 4 is installed; On the slider 9, the slider 9 is installed on the horizontal guide rail 10, and the horizontal guide rail 10 is installed on the frame 1 through the same slider 9 with the servo motor 8; the suction nozzle 6 passes through the hose 11 and the Said raw material tank 5 links to each other;

[0014] It is characterized in that, the surface of the bottom plate of the frame 1 and one side of the workbench 3 are provided with a PLC controller 13, and the PLC controller 13 is connected with a control button 14, and the control button 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com