Pneumatic quick stacker crane for container

A pneumatic, container technology, applied in the stacking of objects, de-stacking, transportation and packaging of objects, etc., can solve the problems of unsatisfactory stacking speed and complex structure of the stacker, so as to shorten the packing time and structure. The effect of simplicity and simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

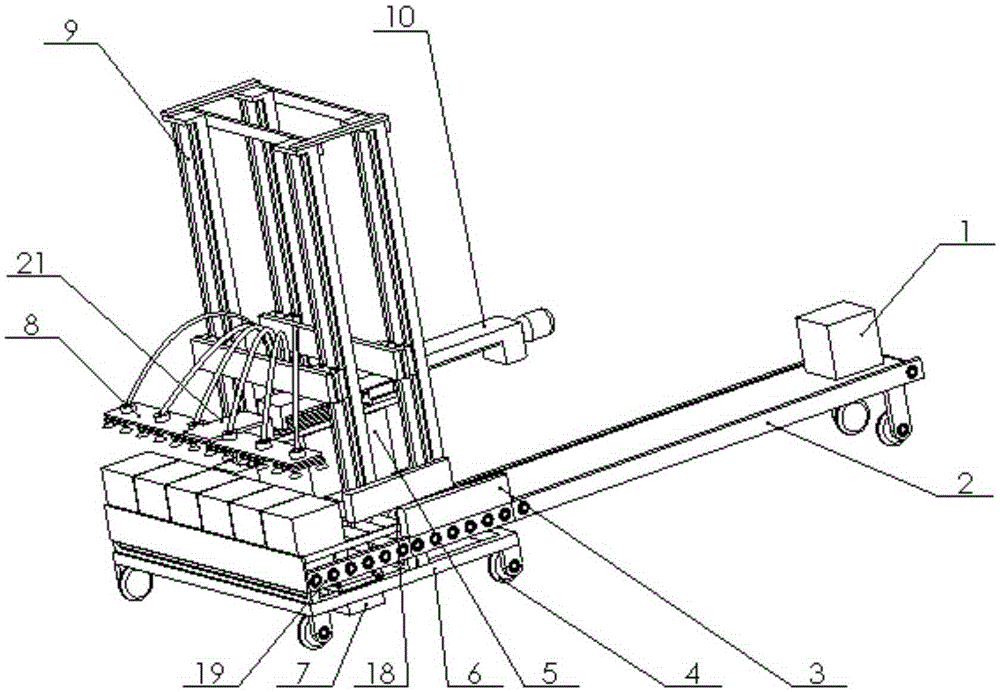

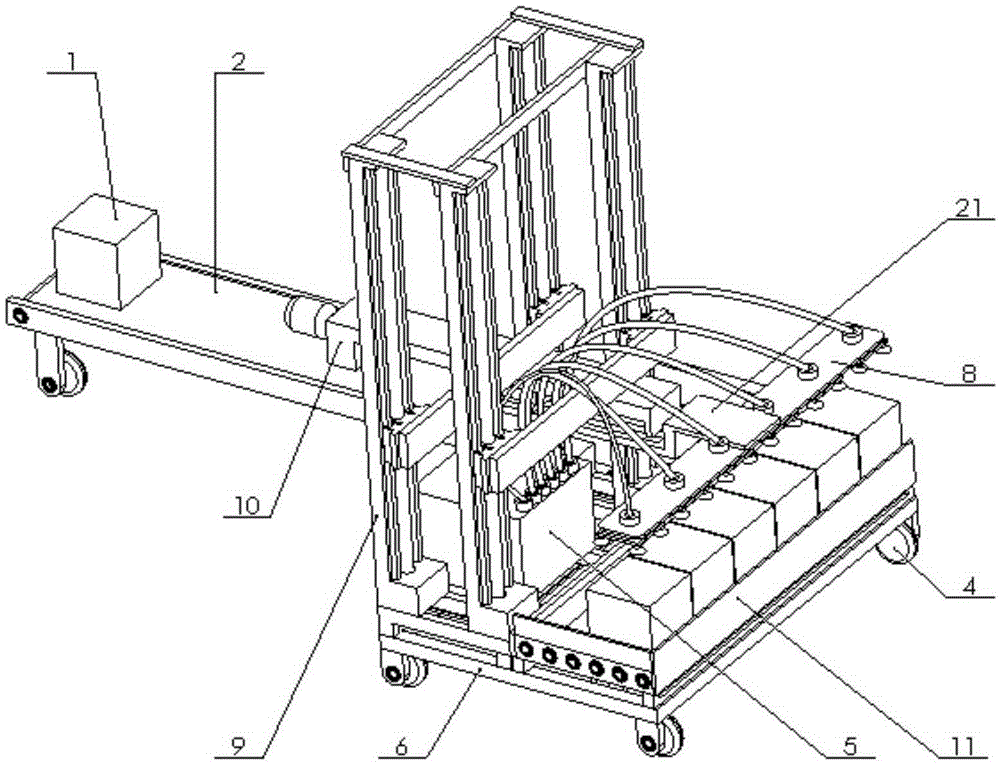

[0021] The present invention will be further described below in conjunction with accompanying drawing.

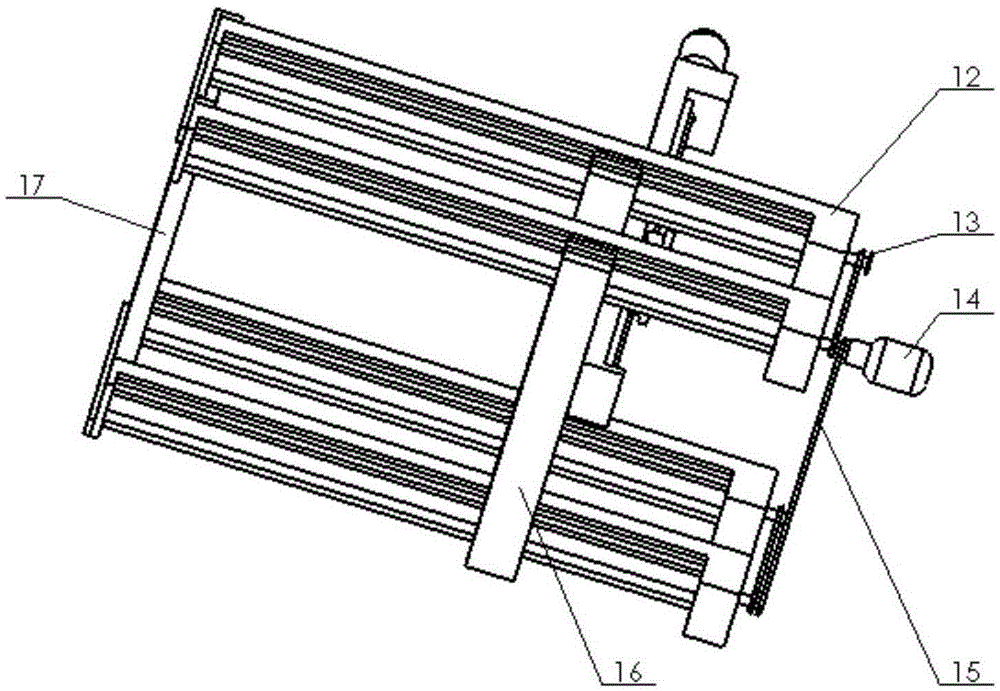

[0022] see figure 1 and 2 , container pneumatic fast palletizer, including frame drive mechanism, PLC controller 5, frame 6, horizontal pushing box mechanism 7, suction cup mechanism 8, lifting mechanism 9, longitudinal pushing mechanism 10 and conveyor belt mechanism 18; lifting mechanism 9 includes four screw guide rail slides 12; the guide rails of the four screw guide rail slides 12 are all fixed to the vehicle frame 6; the front part of the vehicle frame 6 is provided with a roller platform 19, and the driving parts of the horizontal push box mechanism 7 are arranged on the roller platform 19 bottoms, the horizontal push plate 20 is arranged on the top of the roller platform 19 and is driven by the driving parts; the conveyor belt mechanism 18 is arranged on the side of the vehicle frame 6; Push the packing boxes 1 to be placed in a row on the roller platform 19; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com