Ultra-high performance tire tread and synthesis method thereof

A tire tread, ultra-high performance technology, applied in special tires, tire parts, rolling resistance optimization, etc., can solve problems such as poor grip and wear, insufficient dry grip, and inability to meet UHP tires, and achieve rolling Effects of low drag, good wet grip, high cornering stability and safe drivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]Raw material components: 12 parts of natural rubber, 65 parts of solution polystyrene butadiene rubber ANS616 (manufacturer ZEON), 23 parts of solution polystyrene butadiene rubber BNS612, 25 parts of liquid glue LBR-307B (manufacturer KURARAYCO.LTD), 85 parts of high dispersion White carbon black, 25 parts of tackifying resin, 10 parts of anti-aging agent (3 parts of 6PPD, 2 parts of 3100, 2 parts of RD, 3 parts of microcrystalline wax), 2 parts of vulcanizing agent, 8 parts of coupling agent SI75, 2 parts of N220 carbon Black, 5 parts active agent (2 parts ZNO, 3 parts SA), 3 parts accelerator (1 part CZ, 1 part DPG, 1 part TBZTD).

[0051] Preparation process: (this process is carried out in a 270L internal mixer)

[0052] The first step: put in natural rubber, solution polystyrene butadiene rubber A, solution polystyrene butadiene rubber B, liquid glue, carbon black, 50% silica, anti-aging agent, active agent, tackifying resin and mix for 100-120 seconds, The mixing...

Embodiment 2

[0063] Raw material components: 11 parts of natural rubber, 65 parts of NS616, 15 parts of NS612, 15 parts of liquid glue LBR-307B, 75 parts of highly dispersed silica, 20 parts of tackifying resin, 7 parts of coupling agent SI75, 6 parts of anti-aging agent (2 parts of 6PPD, 1 part of 3100, 1 part of RD, 2 parts of microcrystalline wax), 2 parts of vulcanizing agent, 2.5 parts of N220 carbon black, 5 parts of active agent (2 parts of ZnO, 3 parts of SA), 1 part of accelerator TBZTD , 2 parts of other accelerators (1 part of CZ, 1 part of DPG).

[0064] Synthetic method is the same as embodiment 1.

Embodiment 3

[0066] Raw material components: 6 parts of natural rubber, 80 parts of NS616, 25 parts of NS612, 25 parts of liquid glue LBR-307B, 90 parts of high-dispersion silica, 18 parts of tackifying resin, 6 parts of anti-aging agent (2 parts of 6PPD, 2 parts of 3100, 1 part of RD, 1 part of microcrystalline wax), 2 parts of vulcanizing agent, 10 parts of coupling agent SI75, 1.5 parts of N220 carbon black, 6 parts of active agent (3 parts of ZnO, 3 parts of SA), 1 part of accelerator TBZTD , 2 parts of other accelerators (1 part of CZ, 1 part of DPG).

[0067] Synthetic method is the same as embodiment 1.

[0068] Table 1 Main technical indicators of tire tread rubber

[0069]

[0070] It can be seen from Table 1 that the tire tread of the present invention is much better than ordinary high-performance tire treads in terms of rolling resistance and wet grip, and has a better balance with dry grip.

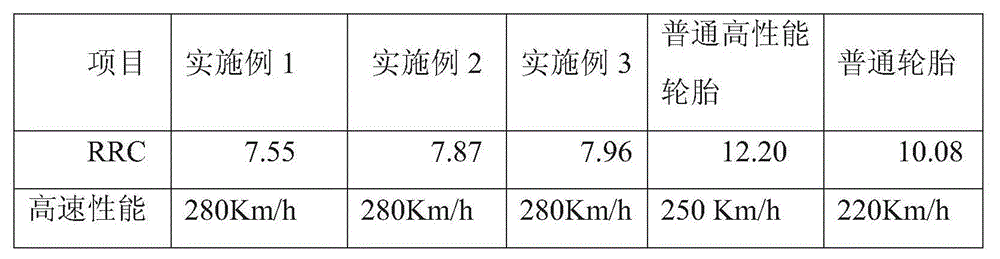

[0071] Table 2 Main technical indicators of tires

[0072]

[0073] Note: RRC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com