Gas well under-pressure induced-flow plug-removal draining technique

A technology of induced blowout and gas well, applied in the direction of wellbore/well parts, earthwork drilling and production, etc., can solve the problems that cannot be realized with pressure swabbing, induce blowout, unplug and discharge liquid, etc., to fill the technological gap, safe and reliable process technology , the effect of reducing operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] A gas well pressure-induced blowout removal plugging removal process, the process steps are as follows:

[0065] 1. Construction steps of pumping and drainage under pressure:

[0066] Ⅰ Installation equipment

[0067] ① On-site layout, vehicle swinging, and derrick;

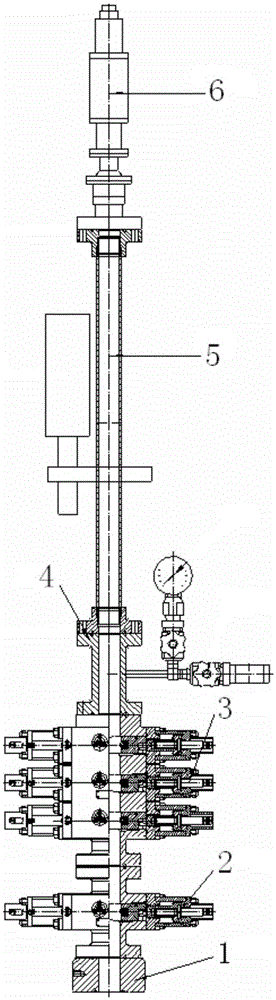

[0068] ② Ground connection wellhead blowout preventer: reducing flange 1, hydraulic single ram blowout preventer 2, hydraulic three ram blowout preventer 3, pressure relief tee 4, blowout preventer 5 connected in sequence, hydraulic The single ram BOP 2 and the hydraulic three ram BOP 3 form a BOP group, and the hydraulic three ram BOP 3 consists of a shear ram BOP, a fully sealed ram BOP and a semi-hydraulic three ram BOP The composition of the ram blowout preventer, such as figure 1 shown;

[0069] ③Install and inspect the wire rope sealer 6, the rope cap, and install the wellhead construction console;

[0070] ④ Remove the threaded flange on the upper part of the original gas production tree, install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com