Maintenance-free slurry washer applied to hazardous environment and working method of maintenance-free slurry washer

A maintenance-free, scrubber technology, used in cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as personal injury, operator personal injury, accelerated damage to sealing materials of mechanical moving parts, etc. , to avoid maintenance and realize the effect of remote control operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

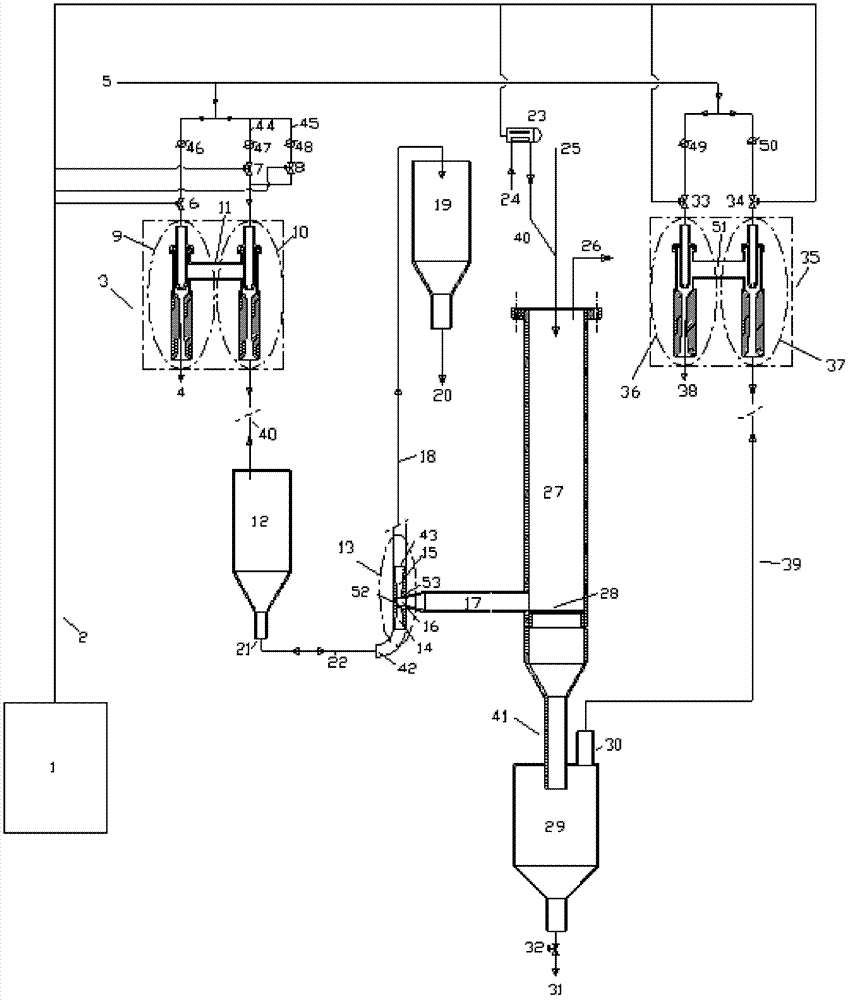

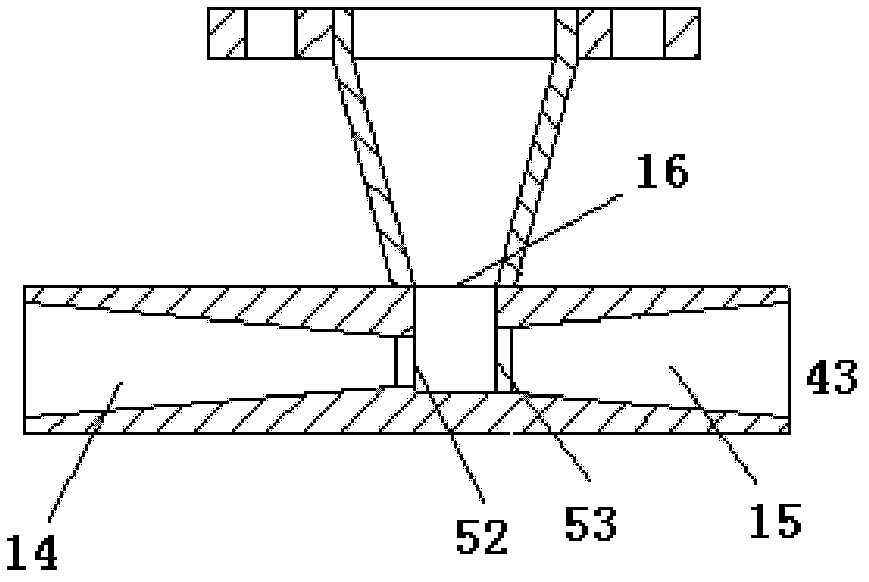

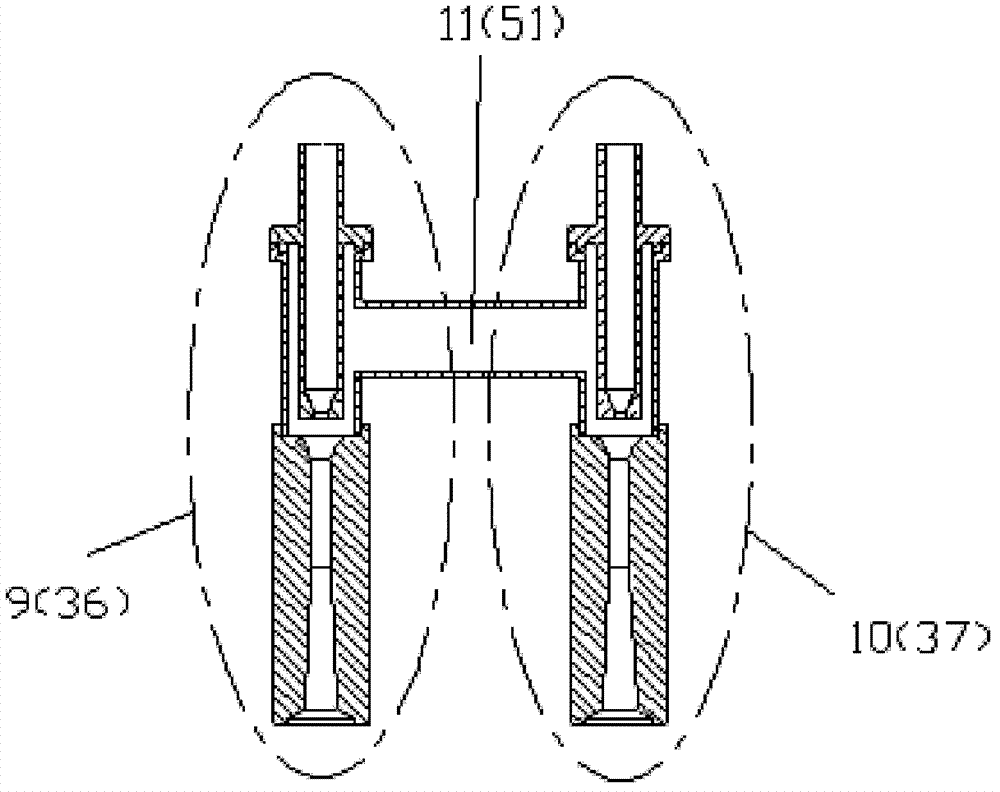

[0016] Such as figure 1 , figure 2 and image 3 As shown, a maintenance-free mud scrubber suitable for use in hazardous environments, the scrubber includes a gas-liquid-solid three-phase fluidized bed 27, the inner bottom of the three-phase fluidized bed 27 is provided with a stainless steel filter screen 28, and the three-phase fluidized bed 27 The bottom is connected with the suction filter box 29 through the pipeline 41; the side of the three-phase fluidized bed 27 is connected with the side port 16 of the jet conveyor 13 through the horizontal horizontal pipe 17; the inlet 42 of the nozzle 14 in the jet conveyor 13 The bottom opening 21 of the piston barrel 12 is connected through the pipeline 22; the outlet 43 of the diffuser 15 in the jet conveyor 13 is connected with the riser 18; the riser 18 is connected with the gas separator 19; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com