Grouting anchor and using method thereof

A technology of grouting bolts and bolts, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of affecting the construction speed of tunneling and supporting, increasing the amount of roadway tunneling and supporting engineering, and increasing project costs. Achieve the effect of simplifying the grouting reinforcement and support process of broken surrounding rock, solving multiple construction problems, and improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

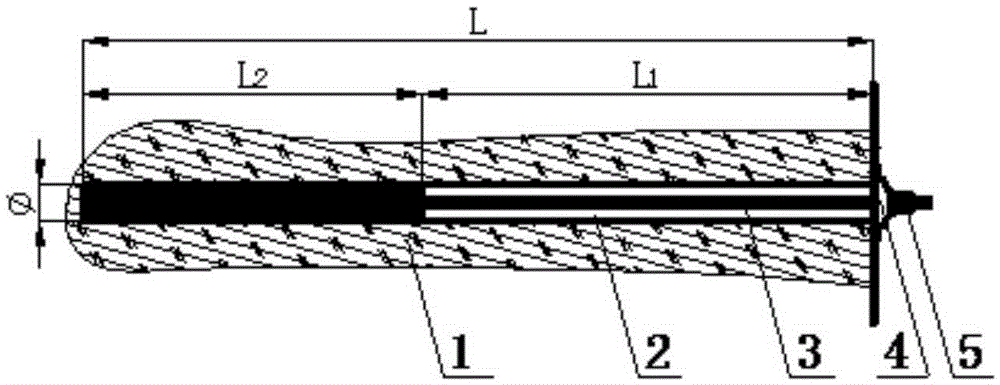

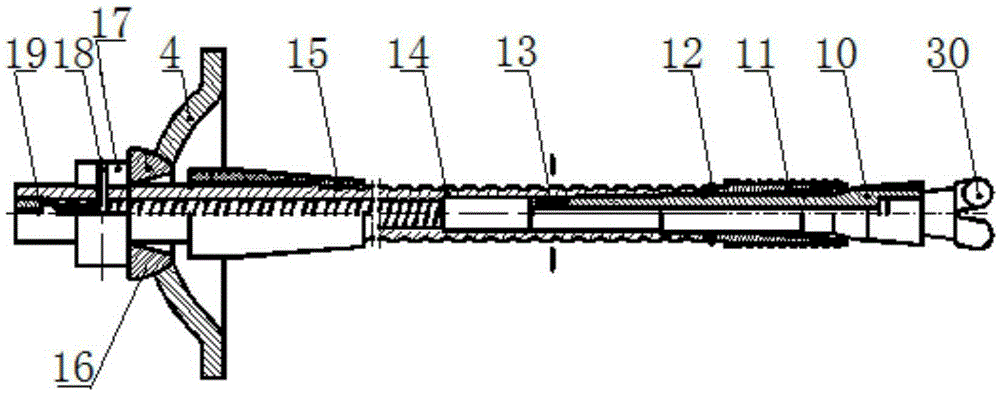

[0049] Such as image 3 As shown, a grouting anchor provided in this embodiment includes a coaxial anchor body, a wedge 10 and a drill bit 30, one end of the wedge 10 is connected to the anchor body, and the other end is connected to the drill bit 30, wherein the drill bit 30 Installed on the front end of the wedge body 10 through a right-handed thread, the front end and the rear end in this embodiment are the right end and the left end in the drawings respectively; there are grouting passages running through the anchor body, the wedge body 10 and the drill bit 30. The grout channel is set on the axis of the bolt body, the wedge body 10 and the drill bit 30, so that it has the function of grouting;

[0050] When the bolt body rotates in the same direction as the drill bit 30 cuts, the relative positions of the bolt body and the wedge body 10 and the drill bit 30 are fixed, and the bolt body drives the wedge body 10 and the drill bit 30 to rotate synchronously, and the drill bi...

Embodiment 2

[0072] A method for using a grouting anchor provided in this embodiment includes the following steps:

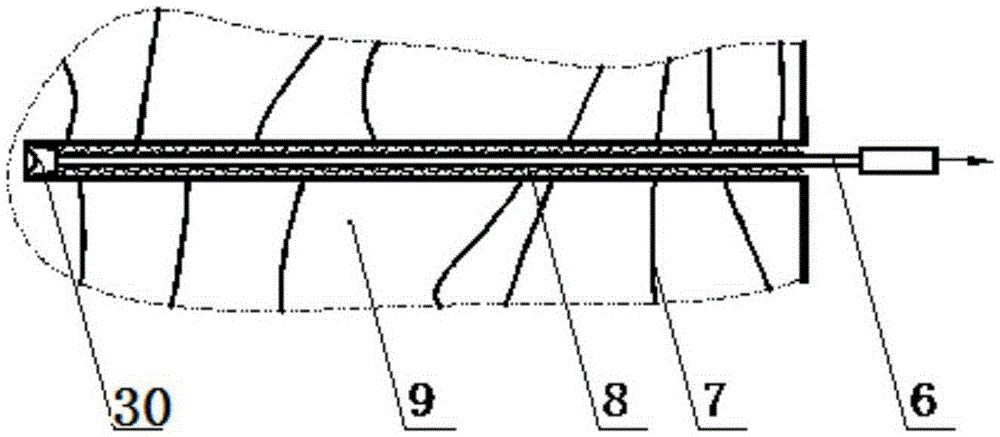

[0073] S1. Drilling: insert the rod tail nut 17 into the rocker drill sleeve, so that the rocker drill rotates forward (outlet shaft rotates to the right), even if the rocker drill rotates in the same direction as the drill bit 30 cuts, the sleeve passes through the rod tail Nut 17 and shear pin 18 drive rod body 14 to rotate clockwise, and the overrunning clutch transmission structure is locked, and wedge body 10 and rod body 14 rotate clockwise synchronously. The wedge body 10 drives the drill bit 30 to cut and break the surrounding rock 9 . As the drilling rig advances, the grouting bolt gradually penetrates into the broken surrounding rock 9 .

[0074] During the drilling process of the grouting bolt, the grouting bolt as a whole remains in the initial assembly state, that is, there is no relative rotation between the wedge body 10 and the rod body 14, the expansion she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com