Single-probe three-coil maglev train gap sensor with fault location function

A gap sensor and fault location technology, applied in the direction of instruments, using electromagnetic means, measuring devices, etc., can solve the problems of inability to install, reduce magnetic field interference, and different signal source frequencies, etc., to facilitate installation, reduce the size of the probe, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

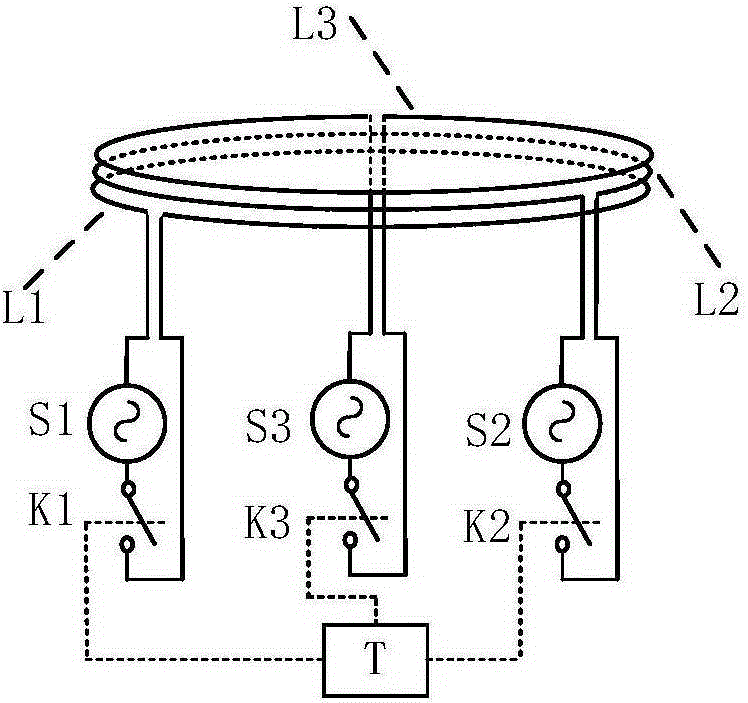

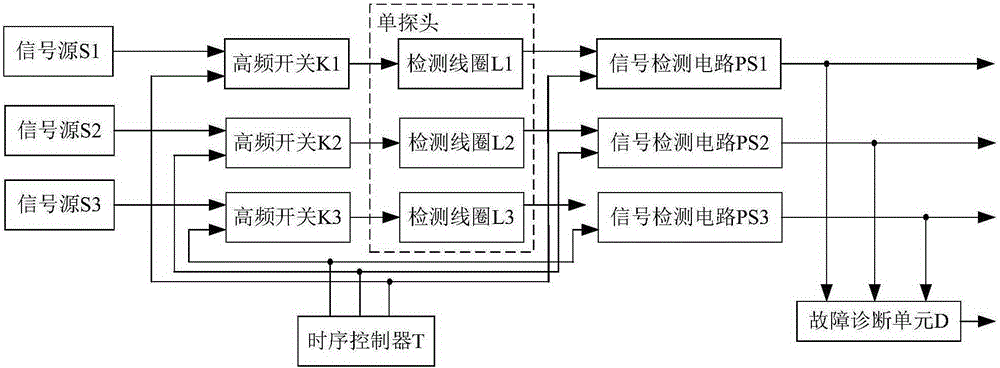

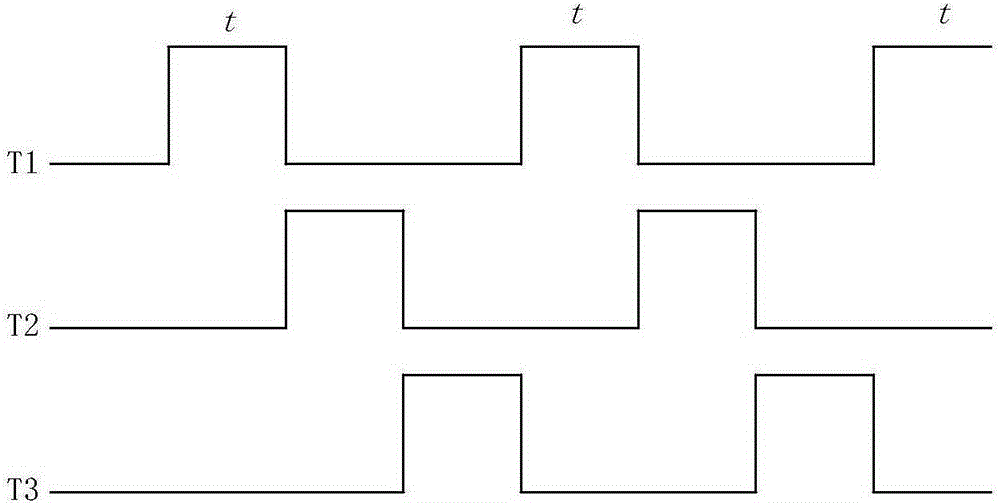

[0019] figure 1 and figure 2 As shown, a specific embodiment of the present invention is: comprising a controllable high-frequency switch connected to the high-frequency signal source on the vehicle body, a probe coil connected to the controllable high-frequency switch, a signal detection circuit connected to the probe coil, A self-diagnosis unit connected to the signal detection circuit; characterized in that the sensor is composed of a single probe, and there are 3 detection coils (L1, L2 and L3) in the probe; the size and winding of the 3 detection coils (L1, L2 and L3) The same direction, and completely overlapped in space; the input terminals of the three detection coils (L1, L2 and L3) are respectively connected to the three high-frequency signal sources (S1, S2) through three controllable high-frequency switches (K1, K2 and K3) and S3); the output terminals of the three detection coils (L1, L2 and L3) are respectively connected to the independent signal detection circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com