Nano step sample scanning measurement type scanning electron microscope

An electron microscope and nanotechnology, applied in scanning probe technology, instruments, etc., can solve the problems that cannot be predicted and controlled, and the measurement uncertainty evaluation of scanning electron microscope is difficult to carry out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with preferred embodiments.

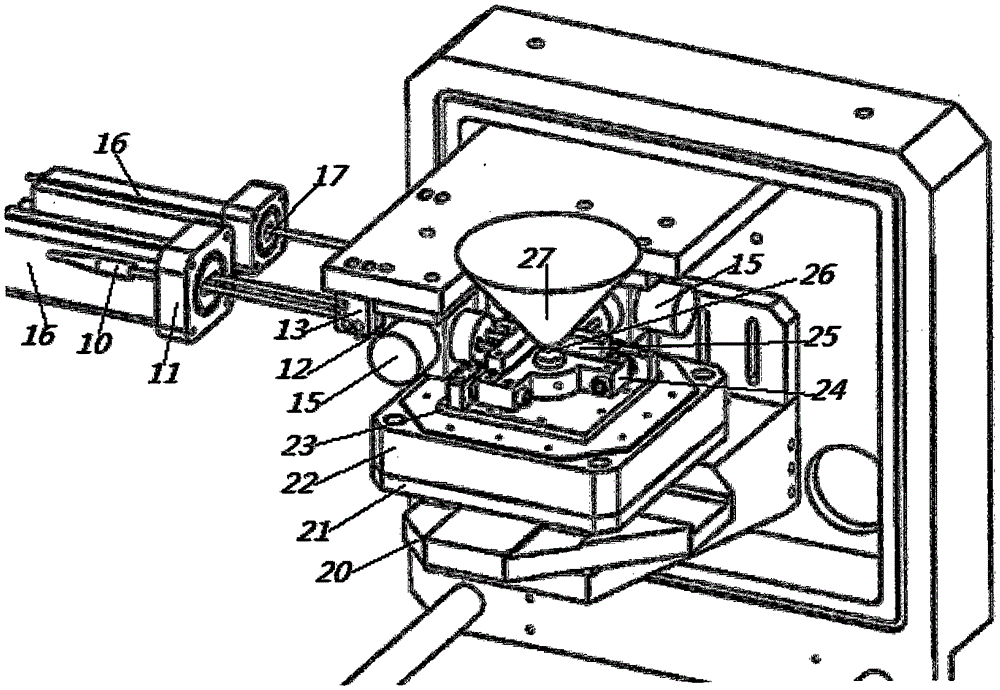

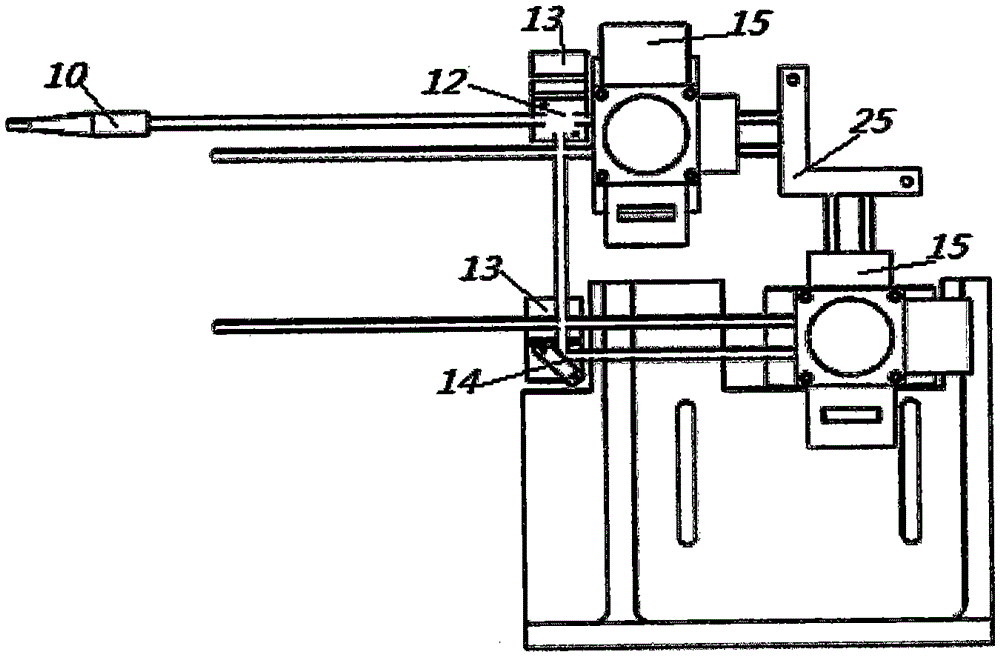

[0024] The present invention provides a nano-stepping sample scanning metrology scanning electron microscope including a high-speed nano-displacement scanning stage, a two-dimensional laser interferometer and an ultrasonic motor coarse-adjustment displacement stage, and the ultrasonic motor coarse-adjustment displacement stage does not include control electron beam deflection the coil. In order to reduce the impact of electron beam drift on the measurement, the ultrasonic motor coarse-adjustment displacement platform adopts a nano-displacement scanning platform with an elastic hinge system whose natural resonance frequency can reach more than 200 Hz when the load is 0.5 kg. The invention uses a two-dimensional laser interferometer to measure the position of the sample stage. The laser beams in two directions intersect with the electron beam of the electron micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com