Wire roll pay-off device during transformer winding process

A technology of pay-off device and transformer, applied in the direction of inductor/transformer/magnet manufacturing, transportation and packaging, electrical components, etc., can solve problems such as loose wires, avoid loosening, avoid self-rotation, and achieve the effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

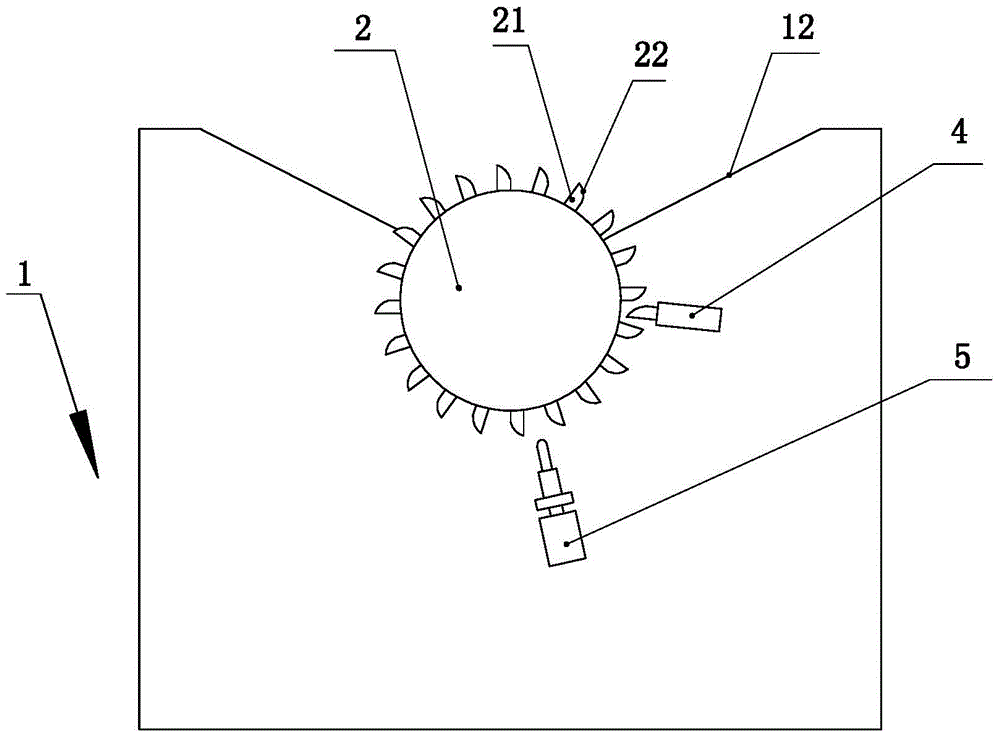

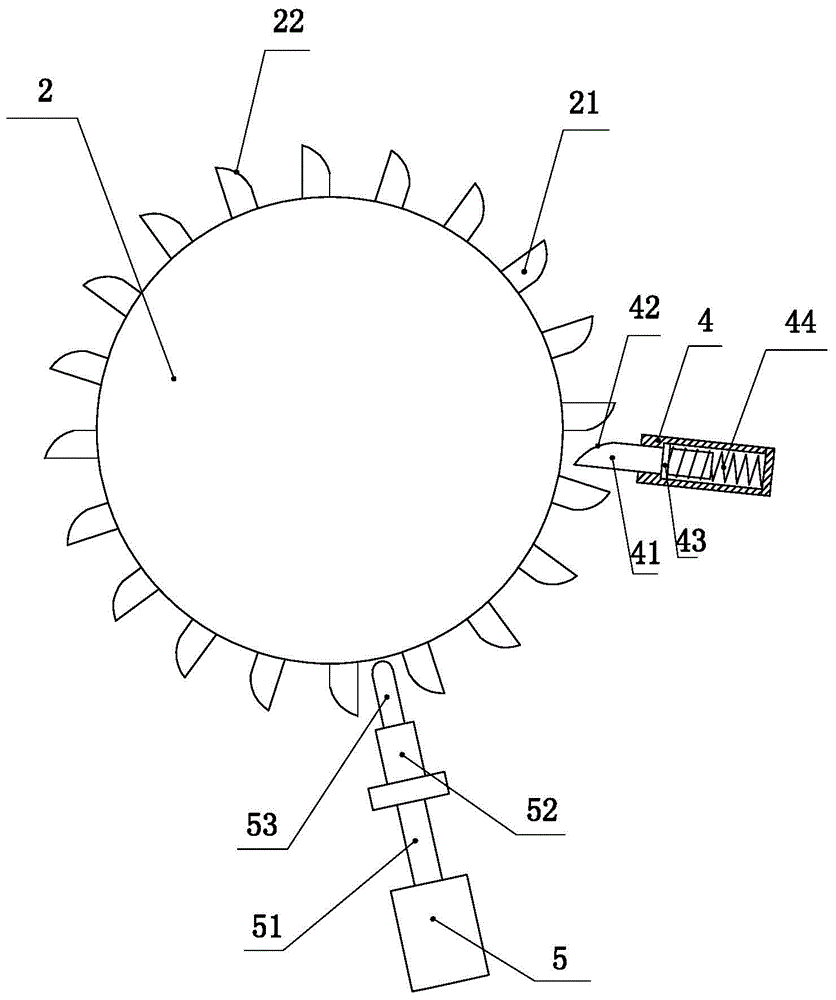

[0020] Such as Figure 1 to Figure 7 As shown, the present invention mainly includes a base 1, a runner 2, a fixer 3, a guide rail 4, a latch 41, a cylinder 5 and a stop pin 53, and the present invention will be described in detail below with reference to the accompanying drawings.

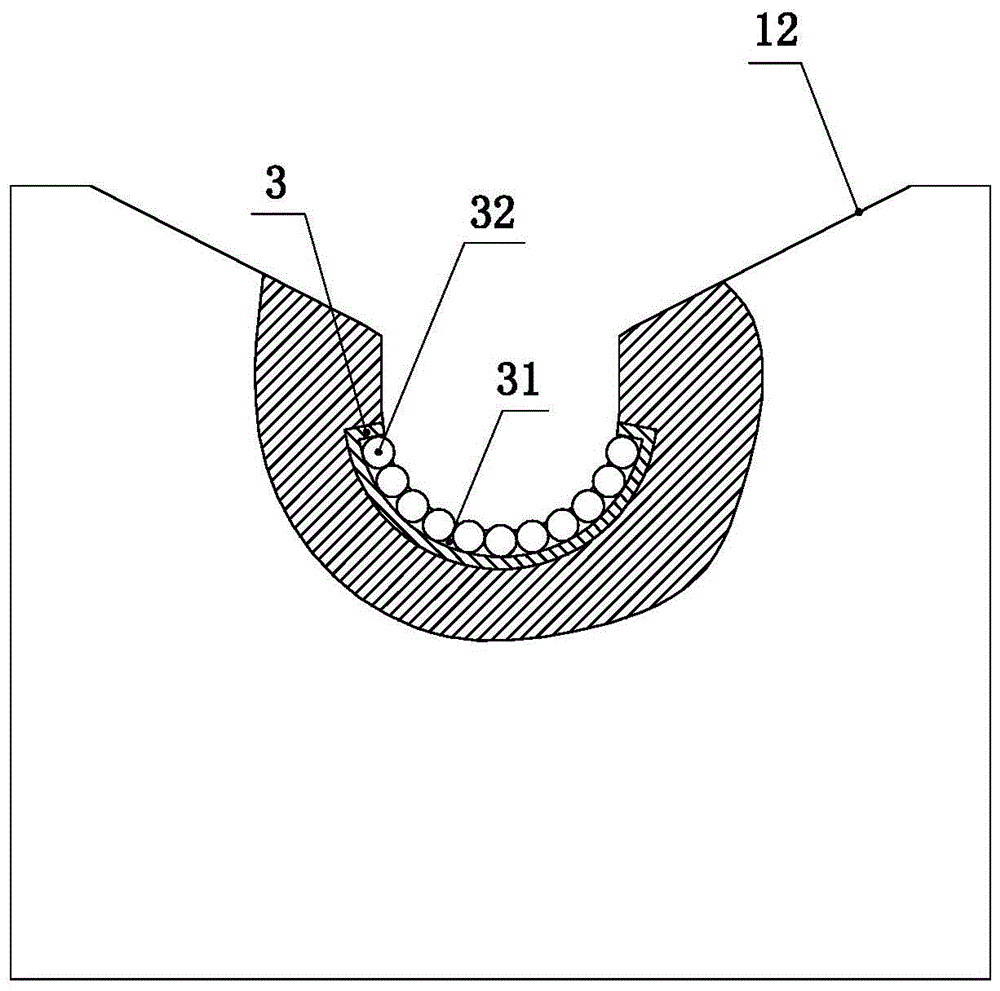

[0021] Such as Image 6 As shown, the base 1 is the base of the present invention, and the left and right sides of the top of the base are respectively provided with vertical plates 11, and the setting of the vertical plates makes the base into a "U" shape. A pair of inclined surfaces 12 are respectively arranged on the top of each vertical plate, and the paired two inclined surfaces are arranged symmetrically, and the lower ends of the two inclined surfaces are close to each other. The setting of the inclined surface is beneficial to place the wire roller on the base, and the axis of the wire roller rolls down along the inclined surface. The lower ends of the two slopes are provided with a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com