Water/alcohol-soluble non-conjugated polymer interface material, organic solar cell device and preparation method thereof

A non-conjugated polymer and organic solar cell technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, electrical components, etc., can solve the problem of increasing the cost of organic/polymer solar cell materials and affecting the wide-ranging market application of solar cells , Prolonging the development cycle of materials and devices, etc., to achieve the effect of cumbersome synthesis methods, low cost, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

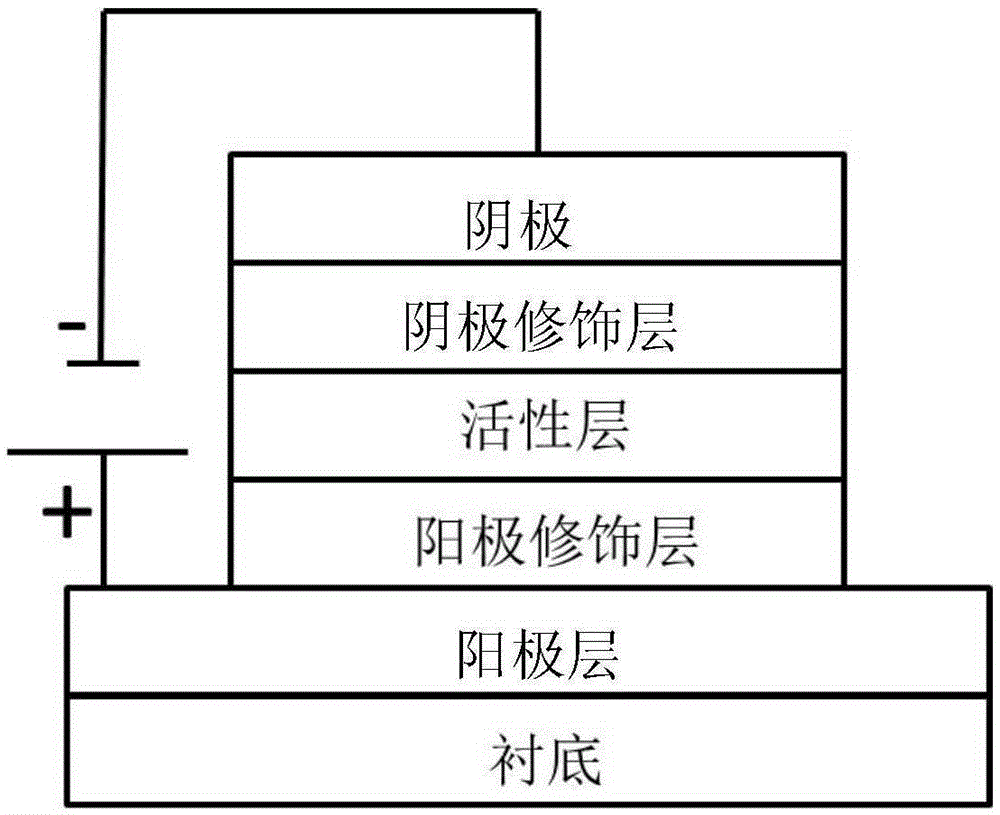

[0032] Embodiment 1 Preparation of upright organic / polymer photovoltaic device

[0033] ITO conductive glass, square resistance ~ 20Ω / m 2 , pre-cut into 15mm x 15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to ultrasonically clean in turn, and place in a constant temperature oven at 80°C for later use. Before use, clean ITO sheets were bombarded with plasma in an oxygen plasma etcher for 4 minutes. And with PEDOT:PSS water dispersion (mass concentration is 1% aqueous solution, purchased from Bayer company), buffer layer is spin-coated with glue homogenizer (KW-4A) at high speed, and thickness is determined by rotating speed, with surface profilometer (Tritek company Alpha-Tencor500 type) is measured and monitored, and the final film thickness is 40 nanometers. After the film is formed, it is annealed at 120° C. for 20 minutes in the air environment to remove residual moisture.

[0034] The conjugated pol...

Embodiment 2

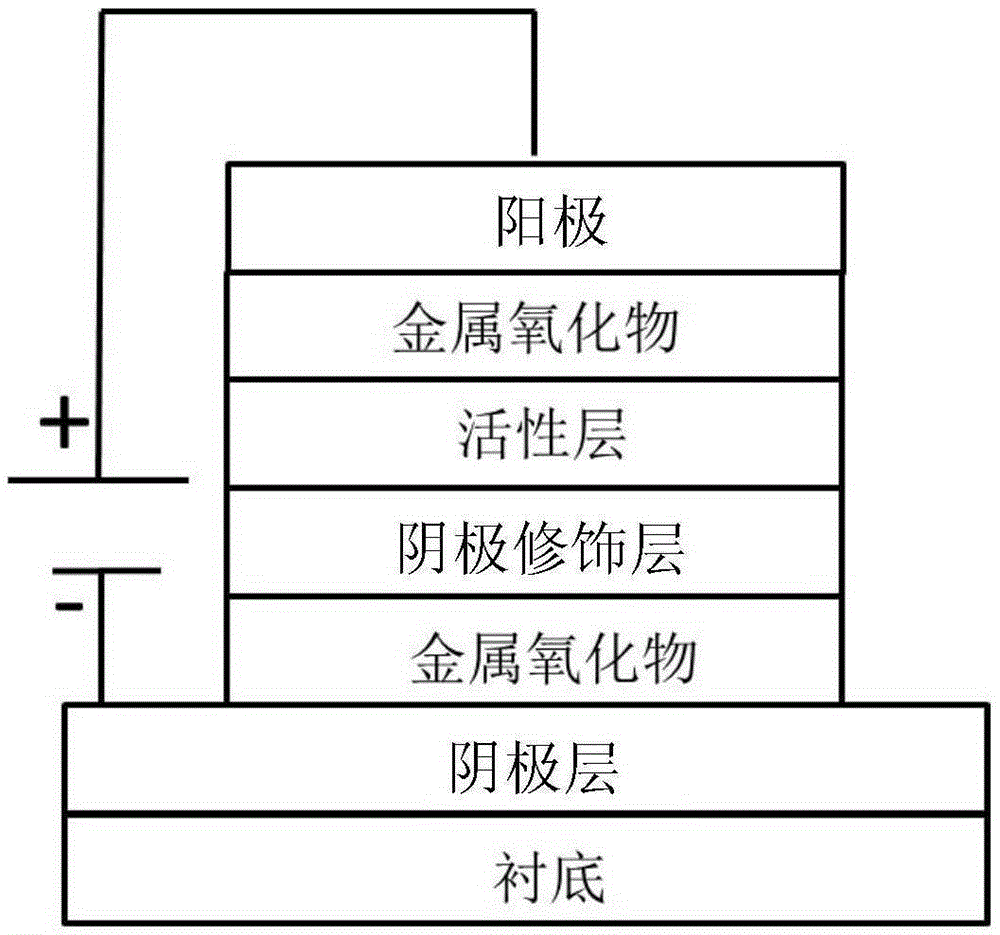

[0035] Embodiment 2 Preparation of inverted organic / polymer photovoltaic device

[0036] ITO conductive glass, square resistance ~ 20Ω / m 2 , pre-cut into 15mm x 15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to ultrasonically clean in turn, and place in a constant temperature oven at 80°C for later use. Then spin-coat a layer of zinc acetate solution on the ITO conductive glass, and then heat it at 200 degrees Celsius for one hour to make it completely hydrolyzed to form a zinc oxide layer. A polyvinylpyridine solution dissolved in an ethanol solvent is prepared on the zinc oxide film layer by spin coating to form a cathode interface modification layer.

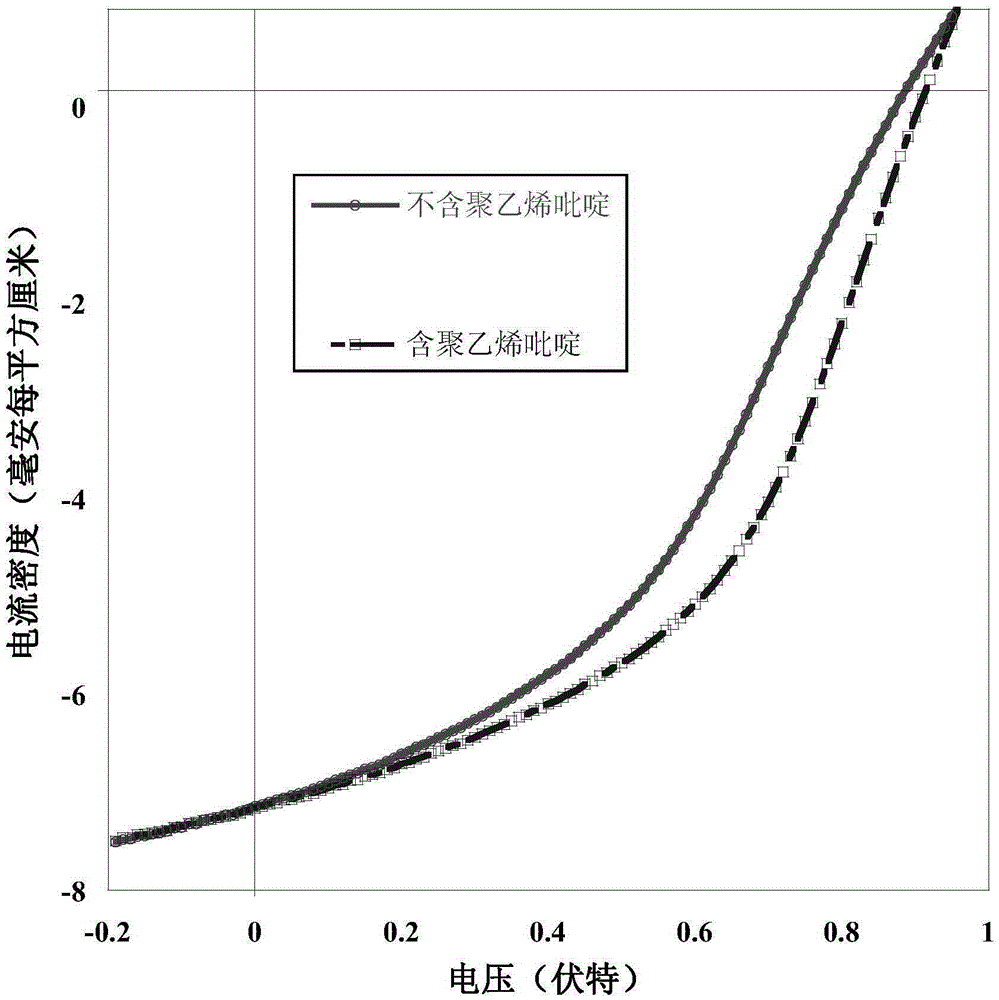

[0037] The conjugated polymer donor material (HBXF: poly(4,9-dihydro-4,4,9,9-tetrakis(4-hexylphenyl)-benzobisindeno[1,2-b:5 ,6-b']dithiophene-alt-10,13-(11,12-difluoro-2,7-dioctyldibenzo[a,c]phenazine)) was weighed in a clean bottle, Go to a special glo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap