Aluminum-based tapping type power transmission bus sectional material

A profile and busbar technology, applied in the direction of docking busbars, cooling busbar devices, fully enclosed busbar devices, etc., can solve the problems of easily affecting normal work, poor stability, and easy heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

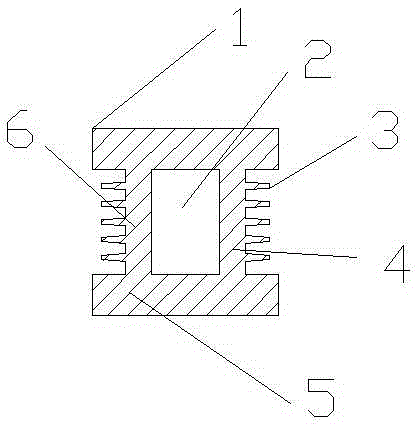

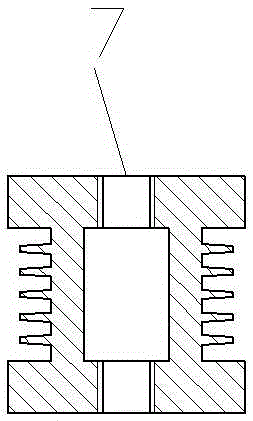

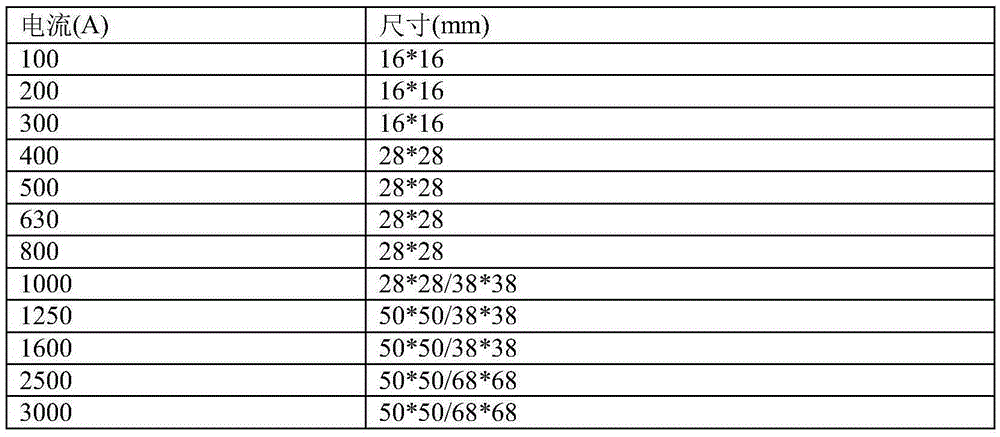

[0019] refer to figure 1 , figure 2 , an aluminum-based split-type power transmission bus profile, its cross-sectional shape is square, with straight holes 7 left on the upper panel 1 and lower panel 5, the cavity 2 is hollow, and the surfaces of the left panel 6 and right panel 4 have edge profiles 5 rows of heat fin structures 3 arranged in parallel and protruding along the length direction. When the power transmission bus section is connected, the upper and lower sides of the connecting plate are used for connection, and the specification below 1000A is left with a straight hole 7, and the bolt is passed through the straight hole 7, and the connection is opposite. For the power transmission bus with a load capacity of 1000A or more, the joints of the profiles are M10 screw holes, which are fastened on both sides.

[0020] After adopting this plan:

[0021] For the specifications below 1000A, a straight hole is left, and the bolt is passed through the straight hole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com