A Diode Clamp Power Switch Series High Voltage Inverter and Its Topological Structure

A technology of diode clamping and high-voltage inverters, which is applied in the direction of converting AC power input to DC power output, output power conversion devices, electrical components, etc. Problems such as voltage imbalance, to achieve the effect of increasing the number of components, good voltage clamping effect, increasing cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

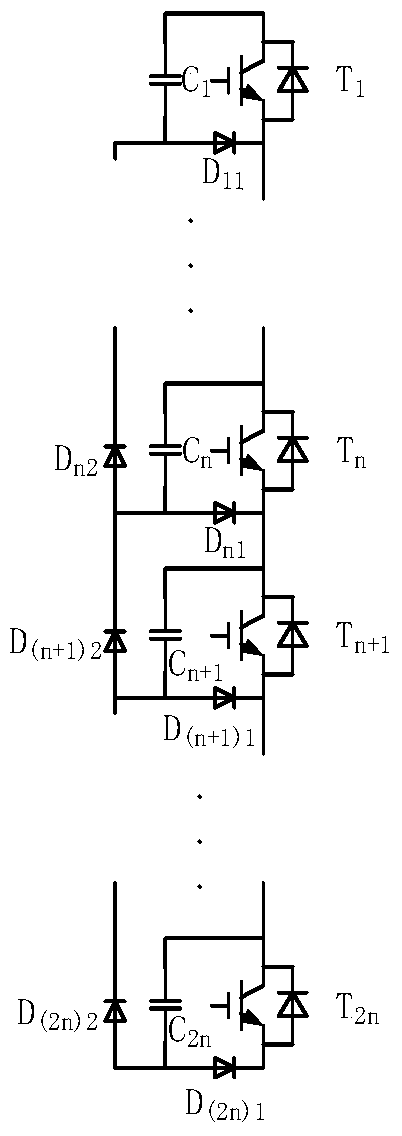

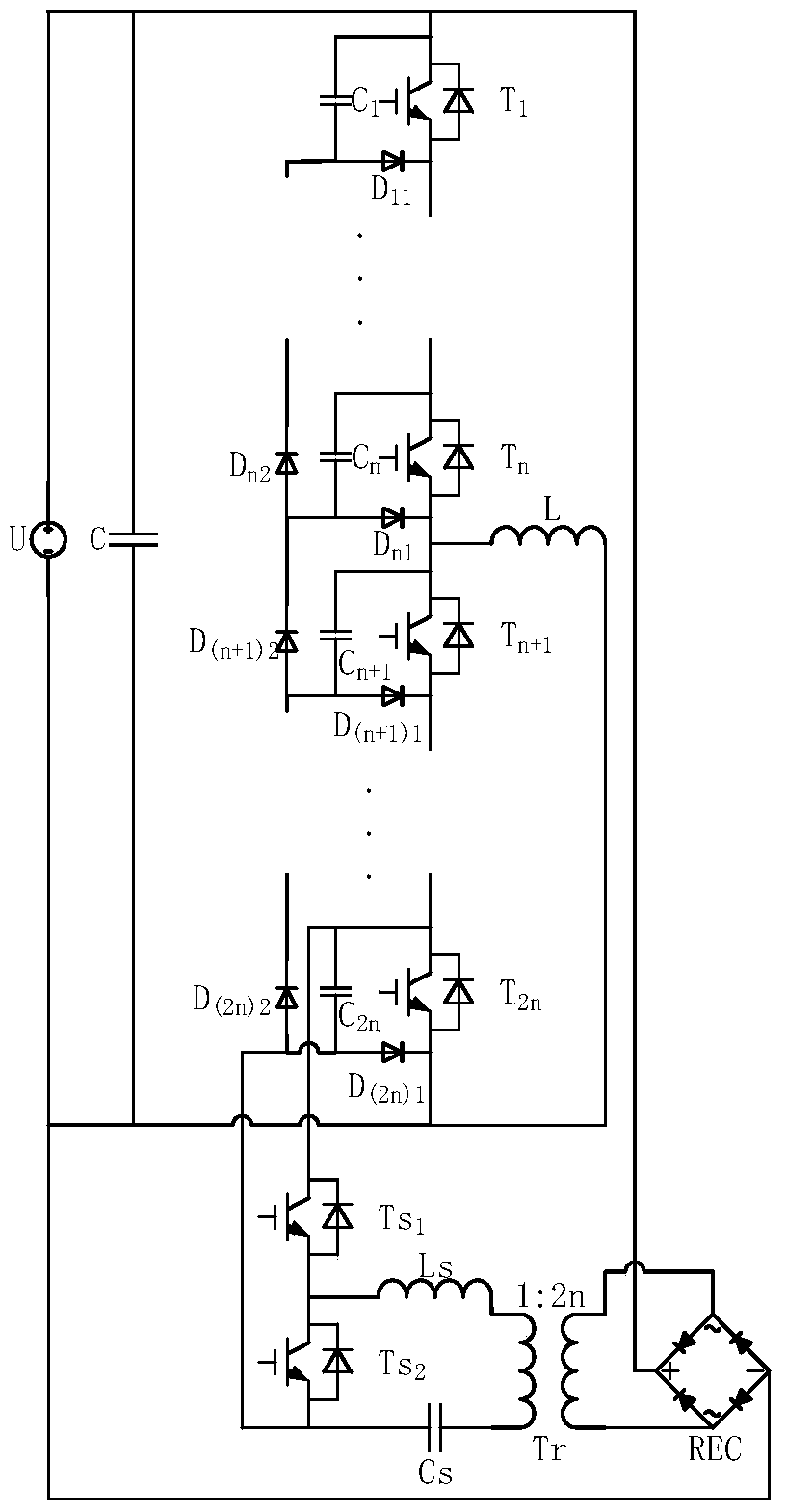

[0028] Embodiment 1: The number of diode-clamped power switch series voltage equalizing units required depends on the voltage level and power level of the working conditions. Take the use of 6 diode-clamped power switches connected in series as a voltage equalizing unit as an example for illustration.

[0029] Such as Figure 4 As shown, the topology disclosed in this embodiment is used for a diode-clamped power switch series high-voltage inverter, including a power switch T i (1≤i≤6), clamping diode D i1 (1≤i≤6), clamp capacitor C i (1≤i≤6), freewheeling diode D i2 (2≤i≤6), auxiliary circuit power switch Ts 1 and Ts 2 , Auxiliary circuit freewheeling inductance Ls, auxiliary circuit blocking capacitor Cs, auxiliary circuit high-frequency transformer Tr (primary and secondary transformation ratio is 1:2n), auxiliary circuit single-phase rectifier bridge REC. power switch Ti (1≤i≤6) collector and clamp capacitor C i (1≤i≤6) connected to one end, the clamping capacitor C ...

Embodiment 2

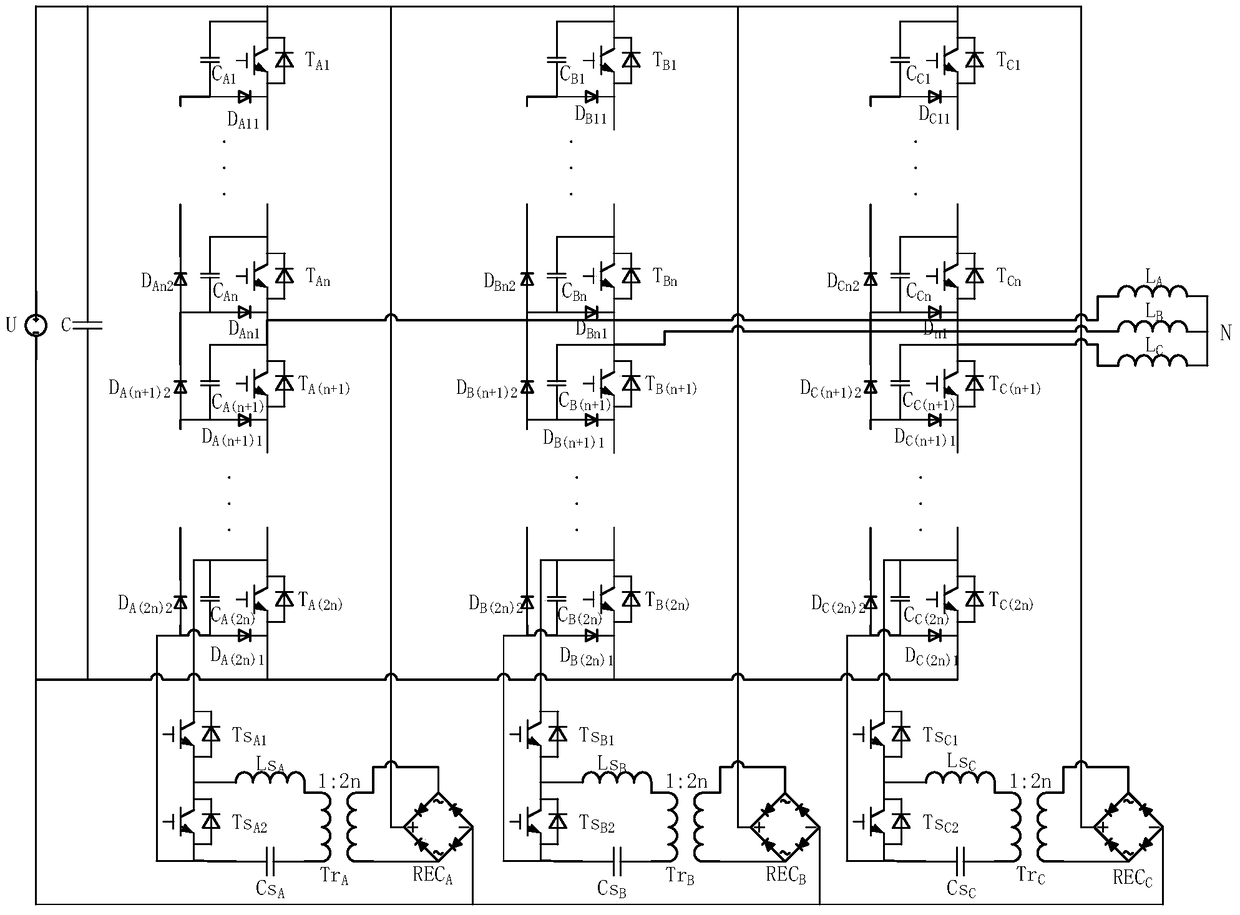

[0032] Embodiment 2: The number of diode-clamped power switch series voltage equalizing units required depends on the voltage level and power level of the working conditions. The single-phase diode-clamped power switch is connected in series with the high-voltage inverter, and 6 diode-clamped power switches are connected in series with the voltage equalizing unit. The three-phase diode-clamped power switch is connected in series with the high-voltage inverter, and 18 diode-clamped power switches are connected in series with the voltage-balancing unit. Take this as an example.

[0033] Such as Figure 6 As shown, a three-phase diode-clamped power switch series high-voltage inverter disclosed in this embodiment is a three-phase three-wire diode-clamped power switch series-connected high-voltage inverter, and the diode-clamped power switch series The high-voltage inverter is used as a single-phase diode-clamped power switch series high-voltage inverter, and the three-phase three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com