Anti-jamming bird feed crusher

An anti-seize and pulverizer technology, applied in feed, grain processing, food science and other directions, can solve the problems of wear of the pulverizing device, affecting work efficiency, jamming, etc., to reduce the wear of parts, high pulverization efficiency, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

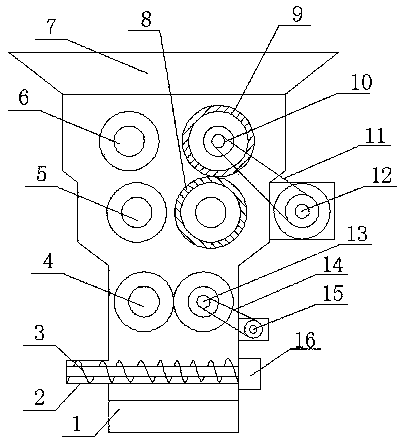

[0015] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention.

[0016] An anti-jamming feed grinder for poultry of the present invention comprises a base 1, a discharge pipe 2, an auger 3, a bottom wheel 4, a middle wheel 5, an upper wheel 6, a feed port 7, a driven gear 8, and a transmission gear 9 , transmission shaft 10, transmission belt 11, motor 12, rotating shaft 13, transmission chain 14, deceleration motor 15 and auger motor 16, wherein, base 1 top is fixedly provided with auger 3, and auger 3 one end end positions are socketed and connected with The other end of the discharge pipe 2 and the auger 3 are fixedly equipped with an auger motor 16, which is fixedly arranged on one side of the box body, and the bottom wheel 4 is arranged above the auger 3, and the bottom wheel 4 is two horizontally tangent Rollers, wherein one of the rollers is sleeved on the rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap