Rotating base for welding

A technology of rotating the base and the base plate, which is applied in the field of tooling and fixtures, can solve problems such as unsatisfactory, inability to use fast welding, and inability to improve production efficiency, etc., to solve poor welding efficiency, improve welding efficiency and welding quality, and solve uneven welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

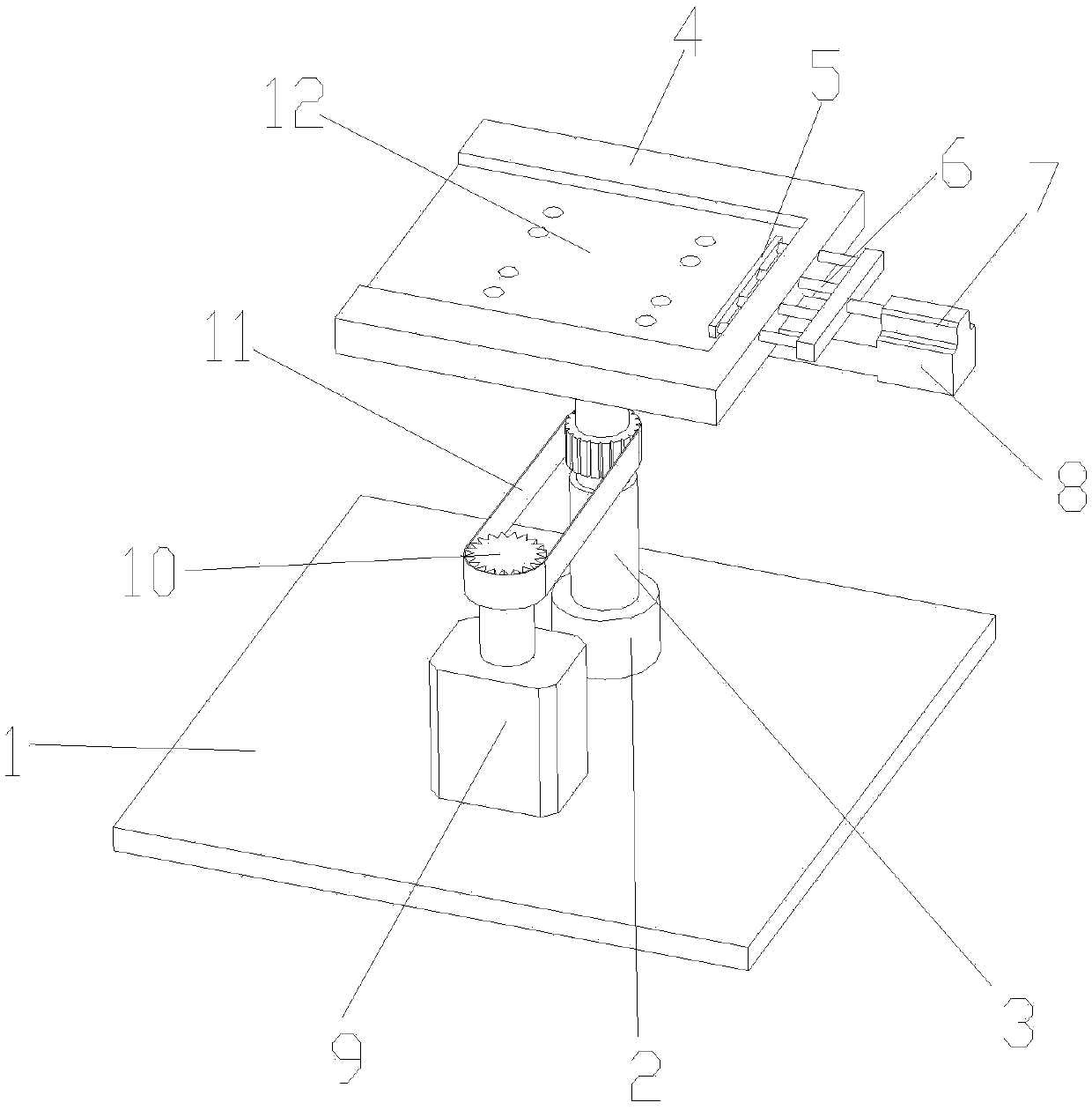

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 Shown is a rotating base for welding according to the present invention, including a base plate 1; a rotating shaft seat 2 is provided on the base plate 1; a support plate 4 connected to a rotating shaft 3 is installed on the rotating shaft seat 2 , the upper surface of the support plate 4 is provided with a card seat groove 12, which is used to place the matching welding card seat and play the role of fixing and clamping. ; The support plate 4 is provided with a push plate 5; the push plate 5 is connected to the push cylinder 7 through the connecting rod 6; the push cylinder 7 is installed on the support plate 4 by a fixed plate 8; One side of the rotating shaft seat 2 is provided with a rotating motor 9; the rotating shaft of the rotating motor 9 is provided with a pulley 10; Belt pulleys 10 used in conjunction with each other; the two pulleys 10 are driv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap