Pipeline external discharge type iron filings recovery device

A technology of recycling device and iron filings, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of easily hurting operators, troublesome collection, damage to Guan Jiedu, etc., and achieve easy collection and reduced potential energy. , the effect of improved controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

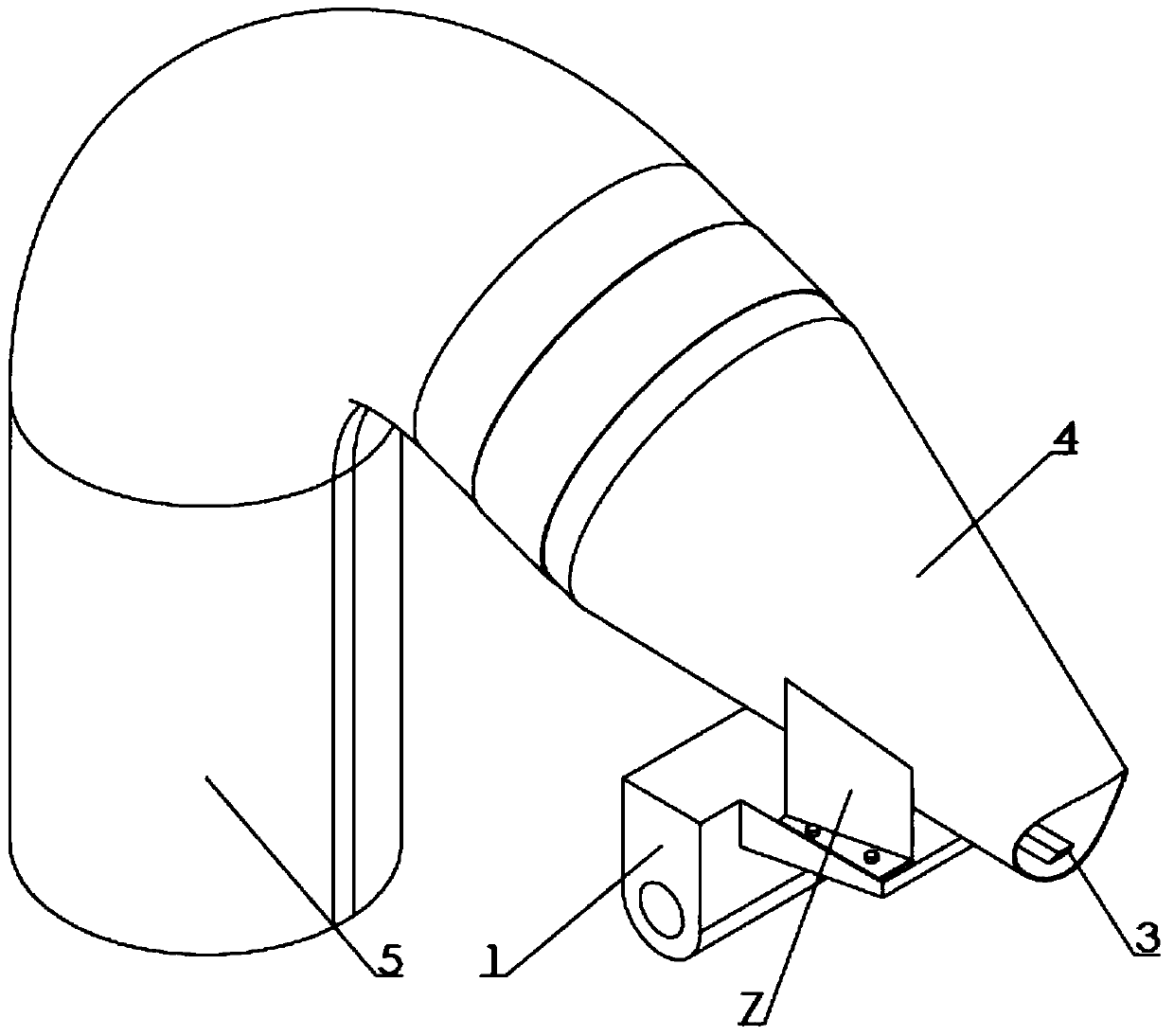

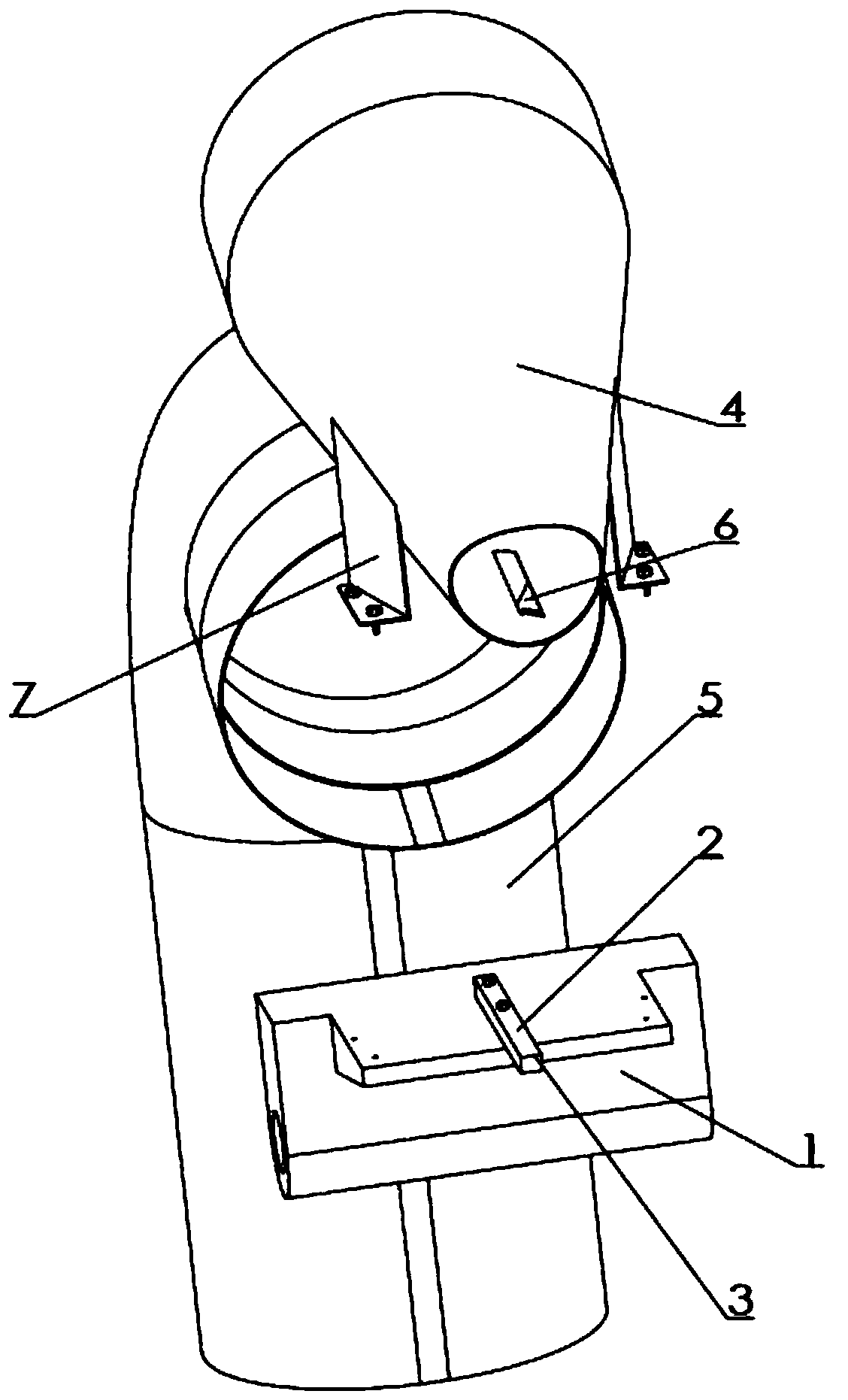

[0011] Examples of the present invention figure 1 , 2 As shown, this kind of pipeline external discharge type iron chip recovery device is provided with a two-dimensional support 1 and a turning tool 2 fixed on the two-dimensional support pointing to the workpiece. The two-dimensional support can move in two dimensions horizontally, close to the Part or move along the axial direction of the car part, the turning tool has a turning blade 3 pointing to the car part; a cone 4 is arranged above the two-dimensional support, the cone angle of the cone in this embodiment is small, and the implementation can be set larger , the guiding effect is stronger, the large-diameter end of the cone is connected to the chip discharge pipe 5 through the interface, the small-diameter end of the cone is facing the workpiece, and the side wall of the cone is provided with a strip-shaped hole 6 with the same width as the turning tool. The strip hole penetrates into the cone, and the turning blade p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com