A zx circle marking and indexing device and circle marking and indexing method

An indexing device and circumference technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of complex circle marking and indexing, and achieve the effects of high marking accuracy, weight reduction and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

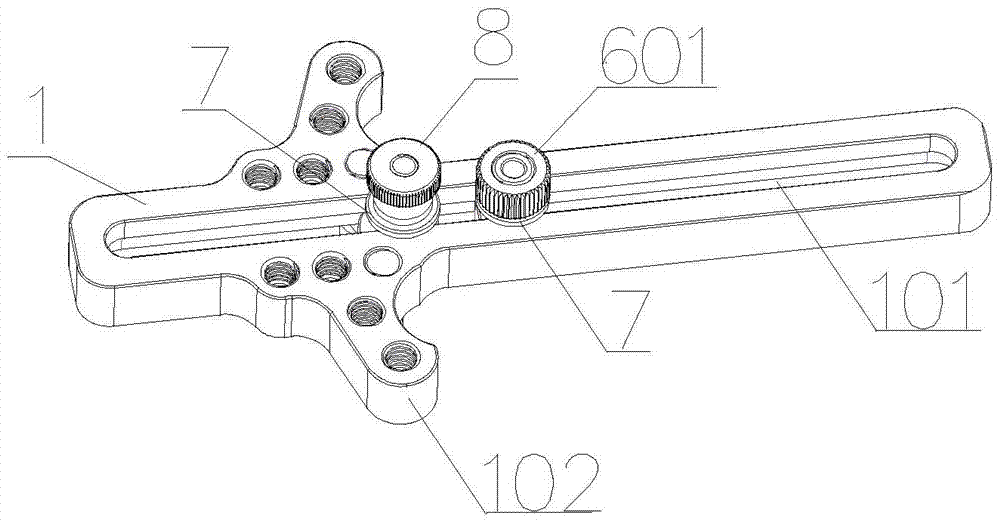

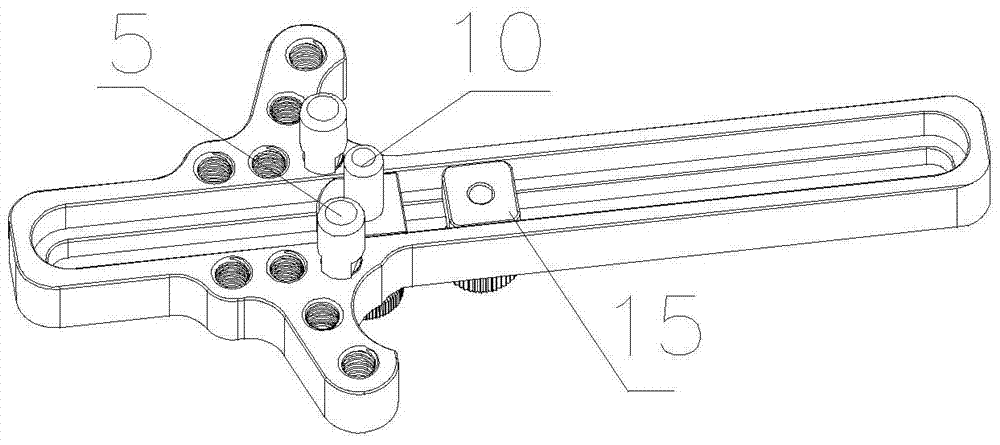

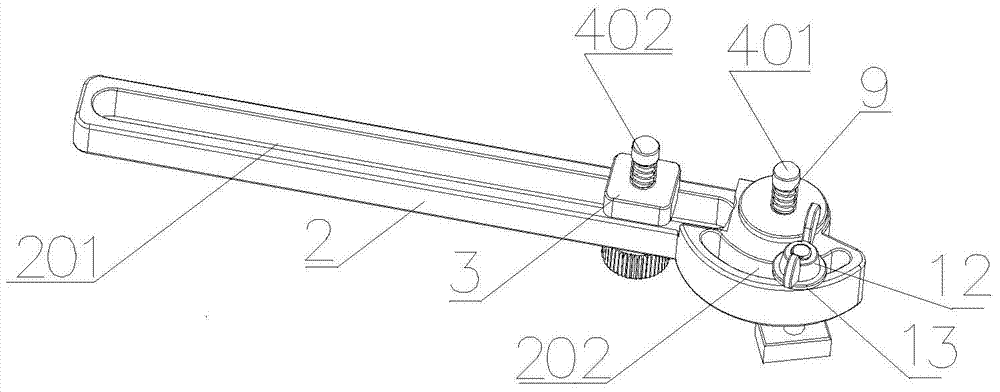

[0079] figure 1 The front axonometric view of the positioning plate of the ZX circular marking indexing device provided for the embodiment of the present invention; figure 2 The rear axonometric view of the positioning plate of the ZX circular marking indexing device provided for the embodiment of the present invention; image 3 The front axonometric view of the hole distance main ruler of the ZX circumferential marking indexing device provided for the embodiment of the present invention; Figure 4 The rear axonometric view of the hole distance main ruler of the ZX circumferential marking indexing device provided for the embodiment of the present invention; Figure 5 The front view of the overall structure of the ZX circumferential marking and indexing device provided by the embodiment of the present invention; Figure 6 The rear view of the overall structure of the ZX circumferential marking and indexing device provided by the embodiment of the present invention; Figure ...

Embodiment 2

[0110] Figure 13 It is a schematic diagram of using the ZX circular marking and indexing device with two hole distance main rulers to perform circumferential marking and indexing of large-sized parts in the way of inner hole positioning.

[0111] Using two hole distances from the main ruler, the positioning punches of the two hole distances from the main ruler are separated on both sides of the positioning plate chute, and the punching rod of one hole distance from the main ruler is inserted into the distance sleeve, and the other hole distance from the main ruler is inserted into the distance sleeve. The punching rod of the main ruler is fixed in the chute of the positioning plate;

[0112] Adjust and fix the positions of the two positioning punches so that the distance between the outer end of the punching rod in the distance sleeve and the outer ends of the two positioning punches is equal to:

[0113] That is to say, it can locate two foreign punching holes at the same...

Embodiment 3

[0117] Figure 14 Schematic diagram of the structure of the ZX circle marking and indexing device with fan-shaped indexing plate provided by the embodiment of the present invention.

[0118] A circle center fastening screw 20 is arranged at the center of the sector indexing plate 16 so that the sector indexing plate can slide or be fixed in the positioning plate chute 101 . Some evenly divided indexing chute 17 is set on the fan-shaped indexing plate 16, as Figure 14 The 9 pieces shown divide the fan-shaped indexing plate 16 into 8 parts; and the auxiliary punches 18 and auxiliary fastening screws 21 that can slide or be fixed in the indexing chute 17 are provided.

[0119] The apex angle of sector index plate 16 is typically 180° so that it has a straight edge 19 .

[0120] Figure 15 It is a schematic diagram of using the ZX circular marking and indexing device with a fan-shaped indexing plate to perform circumferential marking and indexing on parts in the way of inner h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com